Dimos la bienvenida a clientes de Egipto que representan pequeñas y medianas empresas locales de procesamiento de arroz con amplia experiencia en el molienda, envasado y ventas de arroz blanco. Estos clientes han enfrentado desafíos en sus procesos de producción, incluyendo rendimientos de molienda inestables, clasificación insuficientemente precisa y bajos niveles de automatización.

Para mejorar la calidad del producto y la eficiencia del procesamiento, los clientes buscan introducir equipos de molienda de arroz maduros para establecer una planta completa de procesamiento de arroz blanco. Esta línea realizará una serie de operaciones de precisión, incluyendo descascarado, pulido, clasificación y eliminación de piedras, satisfaciendo así la demanda del mercado de arroz de alta calidad.

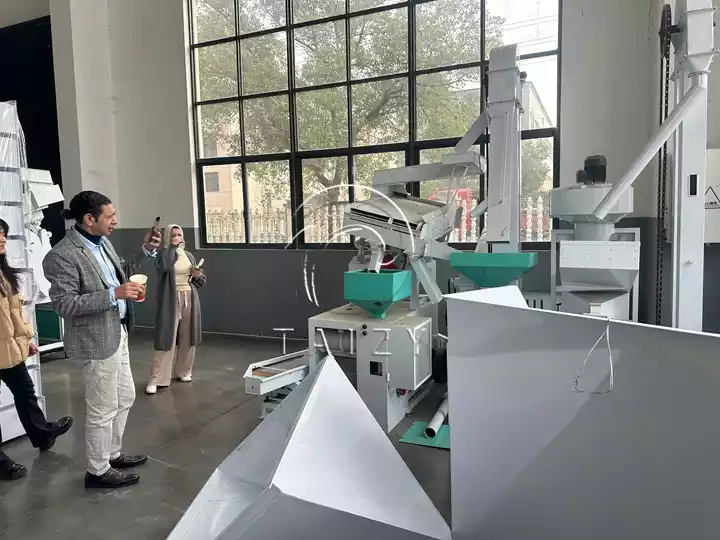

Tour por la fábrica y intercambio en el sitio

El equipo del cliente recorrió nuestro taller de producción de unidades de molienda de arroz, obteniendo información detallada sobre los procesos de operación del equipo y la capacidad de producción.

El personal técnico realizó demostraciones en vivo de los procedimientos de molienda, pulido, clasificación y eliminación de piedras, explicando consideraciones clave y métodos de mantenimiento para cada etapa.

Durante toda la visita, el cliente expresó un gran interés en el nivel de automatización del equipo, el rendimiento de molienda y la capacidad de producción. Participaron en discusiones en profundidad con nuestro equipo técnico sobre configuraciones personalizadas, ajustes de capacidad y servicio postventa.

La visita también abarcó áreas de montaje, pruebas e inspección de calidad, proporcionando al cliente una comprensión integral del rendimiento general del equipo y de nuestras capacidades de fabricación.

Colaboración en la planta de procesamiento de arroz

Tras la visita a la fábrica, el cliente elogió mucho la madurez y fiabilidad de nuestro equipo de molienda de arroz. Indicaron que la inspección de la instalación proporcionó una referencia crucial para sus decisiones de adquisición posteriores. Planeamos confirmar aún más los modelos específicos de equipos y las soluciones de configuración para avanzar en la construcción de la línea de procesamiento de arroz blanco local en Egipto.