Kifaa cha kupanda miche | Mashine ya kupanda | Mashine ya kupanda mboga

Kifaa cha kupanda miche | Mashine ya kupanda | Mashine ya kupanda mboga

Plantskola såmaskinen är specifikt utformad för att så och odla plantor, kapabel att exakt så olika grönsaksfrön i brickor. Genom att täcka undertryck, enhetlig vattning och vetenskaplig hantering möjliggör den att frön snabbt utvecklar rötter och gror inom en kort period.

Jämfört med traditionell manuell plantodling minskar såmaskinen avsevärt arbets- och tidskraven. Den sänker också effektivt sjukdomsfrekvensen, förbättrar överlevnadsgraden för plantor och ger pålitligt stöd för storskalig jordbruksproduktion.

Oavsett om det är i växthus, varmbäddar eller jordlös plantodlingsmiljöer, hjälper såmaskinen bönder att uppnå effektiv och standardiserad plantförvaltning, vilket gör att plantor kan växa hälsosamt i oberoende utrymmen och lägger en solid grund för efterföljande transplantation.

Förutom denna typ av plantskola såmaskin har vi en annan typ, som visas i följande video:

De två frö såmaskinerna har samma funktion och olika utseenden. Kunder kan välja enligt sina behov.

Fördelar med plantskola såmaskin

- Såmaskinen uppnår precis "ett hål, ett frö" sådd, vilket säkerställer att endast en planta växer i varje såhål och förhindrar fröavfall.

- Olika såplattor och frösughuvuden kan bytas ut enligt storleken på olika grödfrön och såddkrav, flexibelt möta kundernas personliga behov.

- Den oberoende håldesignen ger varje planta sitt eget oberoende växtutrymme, vilket förhindrar störningar mellan fukt och näringsämnen.

- Plantodlingscykeln förkortas med 10-20 dagar jämfört med traditionella metoder, vilket resulterar i snabbare tillväxt.

- Rotssystemet förblir intakt och mindre benäget för skador, vilket minimerar transplantationschock. Plantor är mer toleranta mot transport och lämpliga för långdistans transport och standardiserad hantering.

- Frön kan sås i hela brickor på en gång istället för rad för rad, i kombination med en 750-watts importerad roterande fläkt för stark sugning, vilket säkerställer effektiv och kontinuerlig drift.

- Olika typer av såplattor och brickor kan anpassas enligt kundens behov för att rymma olika plantodlingsmetoder och produktionsskala.

Två typer av plantskola såmaskin

Vi har två typer av plantskola såmaskiner: en manuell plantskola såmaskin och den andra är en automatisk plantskola såmaskin. De har alla sina egenskaper och fördelar. Följande är en introduktion med två modeller som exempel.

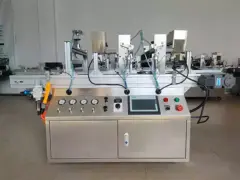

2BXP-5500 frö såmaskin

- Lämplig för stora frön (som sojabönor, ärtor, majs och pumpor), små frön (som petunior, selleri och kål) och konventionella grönsaksfrön (som auberginer, paprikor, tomater och sallad), som uppfyller plantodlingsbehoven för olika grödor med en maskin som tjänar flera syften.

- En enda operation slutför håltagning, fröåtervinning och sådd, vilket effektivt minskar arbetsinsatsen.

- Kompakt storlek, lätt design, enkel struktur, fungerar på 220V ström, redo för omedelbar användning.

- Manuell drift är flexibel, vilket gör att flera användare kan samarbeta, vilket möjliggör snabb storskalig produktion av plantor och förbättrar produktionseffektiviteten.

- Precisionssådd säkerställer enhetlig fröväxt i varje hål, vilket främjar hälsosam plantutveckling.

- Robust konstruktion, lätt underhåll, låga långsiktiga driftskostnader, lämplig för plantproduktionsoperationer av alla skala.

Driftsprocess för manuell frö såmaskin

För det första steget måste du manuellt sätta odlingsjorden i pluggen; i det andra steget, placera pluggen på maskinen, och använd dina fötter för att trampa på maskinen för att uppnå syftet med att trycka hålet och såddoperationen på en gång; det sista steget, ta bort pluggen och lägg sedan lite odlingsjord på den övre delen av pluggen.

Teknisk parameter för 2BXP-5500

| Ukubwa | mm | 1140*630*840 |

| Turbofan | w | 750 |

| Applicerad bricka | mm | 540*280 |

| Totalt 1.5kw (inklusive 0.75kw blåsare) / 220V 50Hz 1-fas | v | 220 |

Hur fungerar maskinen för att så frön?

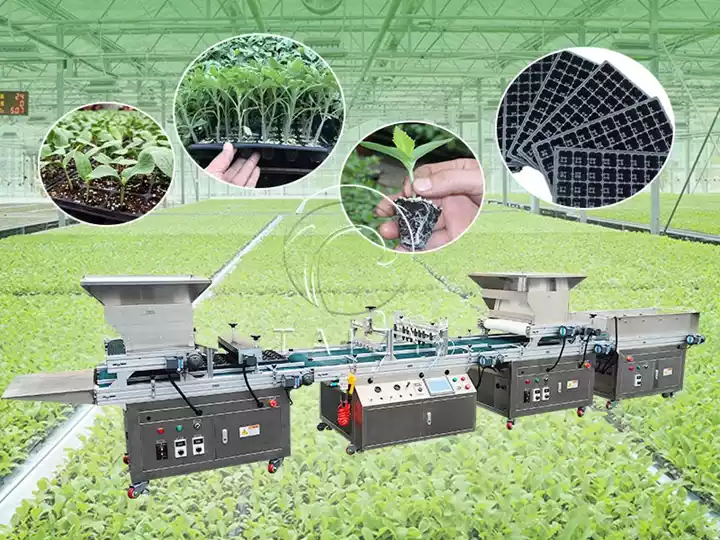

YMSCX-750 grönsaksfrö såmaskin

- Huvudenheten har pekskärmsdrift och integrerar ett jordfyllnadssystem, centralkontroll och hålpressningssystem, såddsystem och bältdrivsystem.

- Den långa produktionslinjens design kan slutföra cirka 750 plantbrickor per timme, vilket avsevärt minskar arbetsinsatsen.

- Säkerställer enhetlig tjocklek av bottenjord, frön och översta jorden, vilket garanterar enhetlig frögroning och enhetlig tillväxt.

- Enhetlig hantering av plantbrickor genom transportsystemet, med bekväm drift, lämplig för storskalig, standardiserad produktion.

Arbetsprocess för plantskola såmaskin

- Plantbrickor transporteras automatiskt på transportbandet

- Applicera bottenjord

- Precisionssådd

- Applicera översta jorden

- Kompakt och komplett transportering

Teknisk parameter för YMSCX-750 plantskola såmaskin

| Mfano | YMSCX-750YMSCX-750 |

| Så effektivitet | 750 brickor/timme |

| Såmetod | Nål sugning med luftblåsfunktion |

| Electric Power | Applicerad frö |

| Sferisk eller icke-sferisk 0.1-5mm (ytan ingen sudd) | Sånoggrannhet |

| Sferisk ≥95%; Icke-sferisk ≥90% | Yttre storlek 540*280mm (32 / 50 / 72 / 105 / 128 / 200 / 288 pluggar) |

| Applicerad bricka | Storlek / Vikt |

| 3350*890*1220mm / 500kg | Luftkompressor (valfritt) |

| ≥ 0.7MPa (för pneumatiskt cylinder drift) | Andra |

| KIMPO vakuumblåsare / 250w växel … | Teknisk data för plantskola såmaskin |

Nyaste arbetsvideon för plantskola såmaskin

Vår försäljningschef, Winnie, diskuterade alla frågor angående plantskola bricka såmaskin med kunden, inklusive produktionskapacitet, sugnålar, frötyper, spänning, fraktagenter och mer. Sedan sa kunden att han skulle återvända till vår fabrik.

En kund från Zambia har köpt en automatisk frö såmaskin från oss. Kunden är en utländsk maskinhandlare. Förutom plantskola såmaskinen köpte kunden också brickor från oss.

Här är en video av kunden som besöker plantskolan och fabriken. Tveka inte att prenumerera på vår YouTube-kanal och fråga om våra plantskola såmaskiner!

Zambisk kund besöker vår fabrik och plantskola såmaskin

Vår fabrik är stark och har tillräckligt med lager. Våra arbetare har rik erfarenhet och tar produktkvaliteten på stort allvar. Varje produkt har kontrollerats på olika nivåer, och kvaliteten kontrolleras strikt. När det gäller leverans använder vi trälådor för förpackning och leverans.

Fabrik

Fördelar med plantskola såmaskin