เราได้ส่งมอบหน่วยขัดข้าวขาว 15 ตันต่อวัน (TPD) ให้กับลูกค้าในมาลาวีอีกครั้ง หน่วยงานแปรรูปธัญพืชที่กำลังเติบโตนี้ ตั้งอยู่ในภูมิภาคผลิตข้าวหลักของมาลาวี มุ่งมั่นที่จะจัดหาข้าวขาวคุณภาพสูงเพื่อตอบสนองความต้องการในตลาดท้องถิ่นและภูมิภาค

ทำไมต้องซื้อหน่วยขัดข้าว?

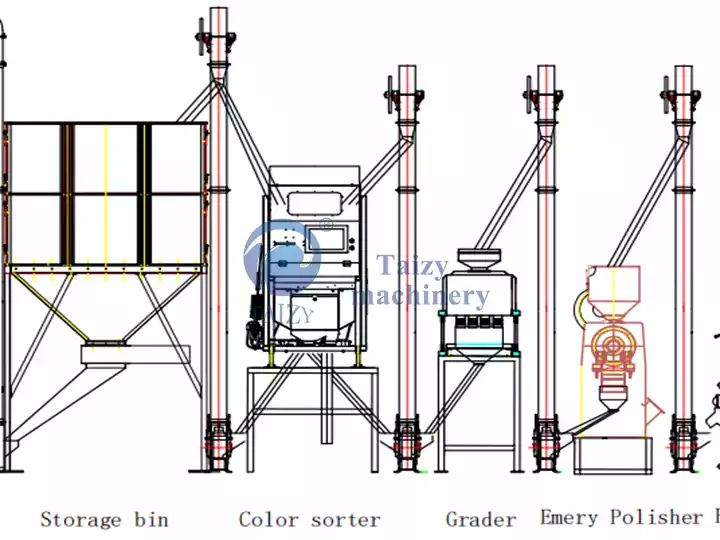

ลูกค้าเลือกใช้เครื่องจักรของเราเนื่องจากมีความเสถียรใช้งานง่าย และครอบคลุมกระบวนการผลิตทั้งหมด—from การขัดและคัดแยกสีจนถึงการคัดแยกสี

เนื่องจากวัตถุดิบของลูกค้าเป็นข้าวขาวคุณภาพสูง การออกแบบสายการผลิตจึงให้ความสำคัญกับกระบวนการขัดและคัดแยกข้าว เพื่อให้ข้าวขาวที่ได้มีลักษณะเรียบเนียนและสีสม่ำเสมอ ตรงตามมาตรฐานการส่งออกและตลาดระดับสูง

เอกสารการโหลดตู้คอนเทนเนอร์หน้างาน

อุปกรณ์ที่ส่งมอบประกอบด้วย: เครื่องขัดข้าว เครื่องคัดแยกข้าว เครื่องคัดแยกสี ถังเก็บ ตู้ควบคุมไฟฟ้า เพื่อความปลอดภัยในการขนส่ง แต่ละเครื่องถูกยึดด้วยกล่องไม้เฉพาะทางเสริมด้วยวัสดุดูดซับแรงกระแทก

ในฐานะอุปกรณ์หลักของสายการผลิตทั้งหมด เครื่องขัดข้าวขาวถูกวางไว้ใกล้ทางออกของตู้คอนเทนเนอร์เพื่อความสะดวกในการยกและติดตั้งในภายหลัง

กระบวนการโหลดตู้คอนเทนเนอร์ทั้งหมดเป็นไปอย่างมีประสิทธิภาพและเป็นระเบียบ โดยมีทีมโลจิสติกส์มืออาชีพคอยดูแลกระบวนการทั้งหมดเพื่อให้แน่ใจว่าอุปกรณ์ถูกโหลดเข้าไปในตู้และปิดผนึกอย่างปลอดภัย

สายการแปรรูปข้าวขาว 15TPD นี้ (รายละเอียดเพิ่มเติม: สายการแปรรูปข้าวปรับปรุง 15TPD พร้อมเครื่องคัดแยกสีและบรรจุภัณฑ์) จะช่วยเพิ่มคุณภาพข้าวและประสิทธิภาพการผลิตอย่างมีนัยสำคัญ ส่งมอบข้าวขาวคุณภาพสูงให้กับตลาดในท้องถิ่น

นอกจากนี้ ลูกค้ายังคาดหวังความร่วมมือระยะยาวกับบริษัทของเราเพื่อแนะนำอุปกรณ์แปรรูปธัญพืชที่มีประสิทธิภาพและอัจฉริยะมากขึ้น