ہماری فیکٹری نے 4 سیٹ مونگ پھلی کے بیج کے چھلکے نکالنے والی مشینیں تیار کیں اور انہیں تنزانیہ بھیج دیا۔ صارف مونگ پھلی کے تیل کے پریسنگ اور مصنوعات برآمد کے شعبے میں مصروف ہے، جس میں مونگ پھلی کی بنیادی پروسیسنگ، خوردنی تیل کی پیداوار، اور زرعی مصنوعات کی بین الاقوامی تجارت شامل ہے، اور سالانہ تقریباً 5000-8000 ٹن چھلے ہوئے مونگ پھلی کا ہینڈل کرتا ہے۔

مشینوں کی بنیادی طلب

- تنزانیہ میں مونگ پھلی کی پروسیسنگ طویل عرصے سے دستی چھلکے اتارنے پر انحصار کرتی ہے، جس میں ٹوٹنے کی شرح زیادہ ہے اور یہ یورپی یونین کے خوردنی تیل برآمدی معیار کو پورا کرنے میں مشکل ہے۔

- TBH-800 مشین کا ہائی-پریسیژن اسکرین سسٹم (2 معیاری 2 اضافی) مختلف اقسام کی مونگ پھلی کے لیے موزوں ہے، اور ٹوٹنے کی شرح کو 5% سے کم کنٹرول کیا جا سکتا ہے۔

- تنزانیہ میں کم از کم 10% بجلی کی فراہمی کے موجودہ حالات کے سبب، یہ سامان 8hp ڈیزل انجن سے چلتا ہے۔

- 1330x750x1570mm کے کم حجم کے ساتھ، اسے دور دراز کے علاقوں میں عارضی پروسیسنگ سائٹس قائم کرنے کے لیے استعمال کیا جا سکتا ہے، فصل کی کٹائی کے دوران مرکزیت سے پروسیسنگ کے مسئلے کو حل کرتا ہے۔

گراؤنڈ نٹ بیج کے چھلکے نکالنے والی مشین کی خصوصیات

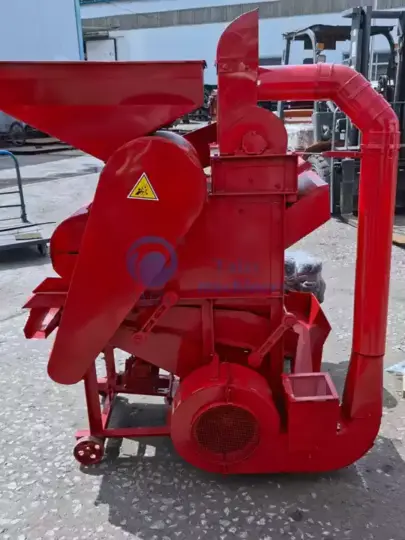

اس وقت فراہم کی گئی TBH-800 مونگ پھلی کے چھلکے نکالنے والی مشین تین اہم انوکھائیوں کو حقیقت بناتی ہے جو افریقی مارکیٹ کی خصوصیات کے مطابق ہیں۔

- 4 قابلِ تبدیل اسکرینیں مختلف مونگ پھلی کی اقسام اور عمل کے مراحل کے لیے موزوں ہیں۔

- ڈبل بلیور ڈیزائن چھلکوں اور بیجوں کی مؤثر علیحدگی کو ممکن بناتا ہے، اور ثانوی دستی صفائی کے اخراجات کو کم کرتا ہے۔

- 8hp انجن مستحکم آپریشن کو یقینی بناتا ہے بغیر کسی گرڈ کے ماحول میں، اور ہُوکا ساختہ مشین کے ارتعاش کی مزاحمت کو بڑھاتا ہے۔

اس گراؤنڈ نٹ بیج کے چھلکے نکالنے والی مشین کے بارے میں مزید جاننے کے لیے یہاں کلک کریں: مونگ پھلی کے چھلکے نکالنے والی مشین برائے گراؤنڈ نٹ کی فصل

اس تعاون کو ایک نقطہ آغاز کے طور پر لیتے ہوئے، صارف 30% پیداوار کی صلاحیت میں اضافہ کرنے کا ارادہ رکھتا ہے، اور مونگ پھلی کے تیل، مونگ پھلی کے مکھن، اور دیگر گہرے عمل شدہ مصنوعات کی علاقائی مارکیٹوں جیسے کینیا اور جنوبی افریقہ میں توسیع کی حمایت کرتا ہے۔