Mesin Ekstraksi Minyak Kacang Tanah dan Wijen Mesin Ekstraksi Biji Minyak

Mesin Ekstraksi Minyak Kacang Tanah dan Wijen Mesin Ekstraksi Biji Minyak

Peralatan ekstraksi minyak | Pemeras minyak otomatis

Fitur Sekilas

Mesin ekstraksi minyak otomatis pemeras minyak sekrup adalah peralatan ekstraksi minyak yang efisien dan hemat energi, yang banyak digunakan di pabrik minyak kecil dan menengah serta bengkel keluarga dengan tingkat konversi minyak 20%-50%.

Dibandingkan dengan metode ekstraksi minyak tradisional, hasil minyak dari peralatan ini meningkat sebesar 4% hingga 6%, dan konsumsi energi berkurang sekitar 60%, yang secara signifikan meningkatkan efisiensi produksi dan manfaat ekonomi.

Seri mesin minyak ini mudah dioperasikan, memerlukan ruang kecil, dan cocok untuk pengepresan panas dan dingin berbagai tanaman minyak. Cocok untuk lebih dari 30 tanaman biji minyak seperti kacang tanah, kedelai, wijen, rapeseed, dll. Tingkat residu minyak dari ampas kering hanya 0,5%-3,5%, dan kapasitas produksi mesin tunggal berkisar dari 15kg/jam hingga 550kg/jam.

Menurut kebutuhan produksi yang berbeda, tersedia berbagai model seperti 6YL-60, 6YL-70, 6YL-80, 6YL-100, 6YL-125, dll., untuk memenuhi kebutuhan beragam pengguna.

Mesin pemeras minyak sekrup yang laris

Mesin pemeras minyak otomatis dapat mewujudkan filtrasi vakum. Suhu yang berbeda dapat diatur sesuai bahan yang berbeda.

Memutar pegangan dapat menyesuaikan tekanan yang diperlukan untuk memeras bahan. Jumlah minyak yang diperas sekaligus juga berbeda untuk tekanan yang berbeda, dan ketebalan ampas minyak juga berbeda.

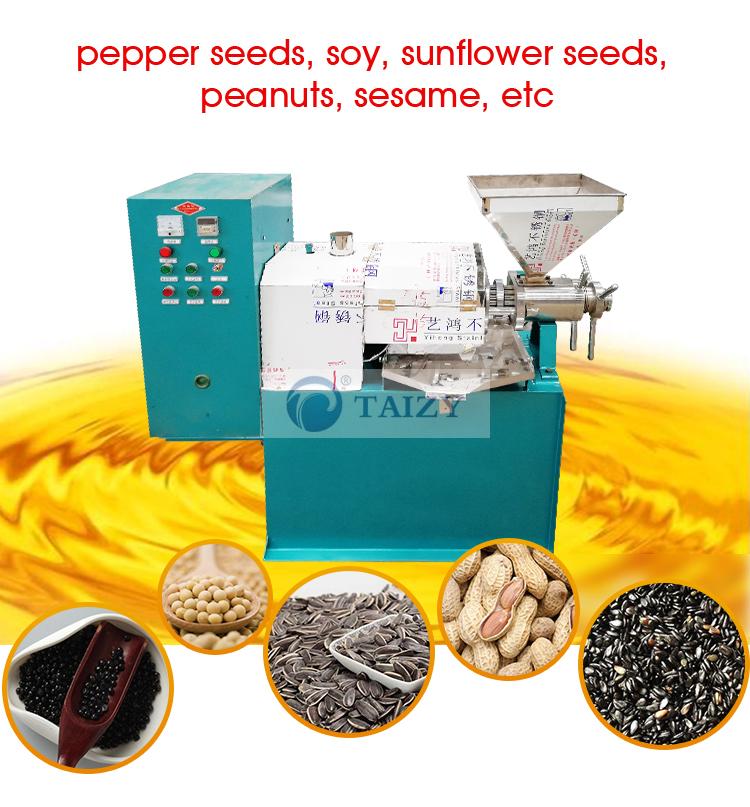

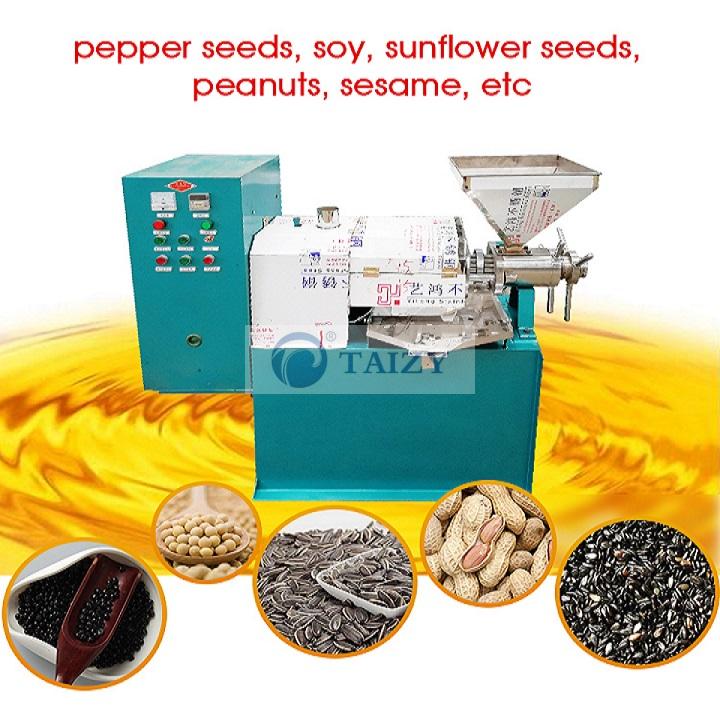

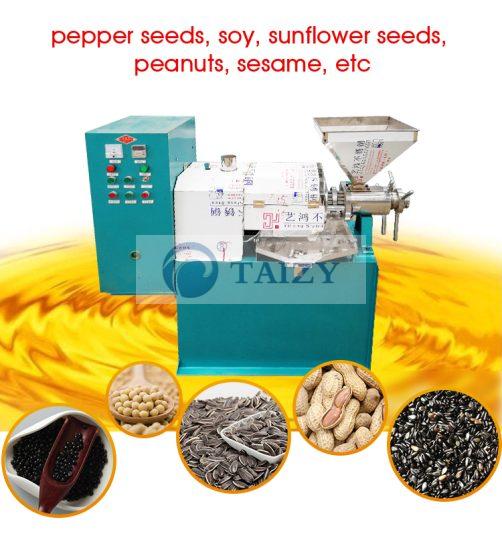

Bahan yang cocok untuk pemeras minyak sekrup

Mesin pemeras minyak sekrup kami cocok untuk kacang tanah, rami, wijen, rapeseed, bunga matahari, biji kapas, kedelai, kenari, biji lada, biji tung, jarak pagar, almond, dll.

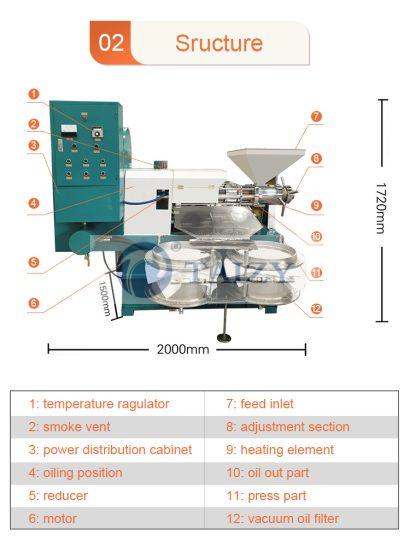

Struktur ekstraksi minyak dengan pemeras sekrup

Struktur mesin pemeras minyak sekrup mencakup pengatur suhu, ventilasi asap, kabinet distribusi bubuk, posisi pengolahan minyak, reduktor, motor, saluran masuk bahan, bagian penyesuaian, elemen pemanas, bagian keluaran minyak, bagian pengepres, filter minyak vakum, dll.

Prinsip kerja ekstraktor minyak sekrup

Dalam mesin pemeras minyak sekrup, bahan baku masuk ke ruang pengepres dari hopper. Kemudian, mereka didorong ke dalam oleh sekrup untuk diperas.

Tekanan tinggi dan gesekan antara bahan, sekrup, dan ruang menciptakan gerakan relatif dan menghasilkan panas, membantu proses ekstraksi minyak.

Diameter sekrup yang meningkat dan pitch yang menurun mendorong bahan ke depan dan keluar. Sementara panas gesekan membantu denaturasi protein, meningkatkan plastisitas, dan mengurangi viskositas, sehingga meningkatkan hasil minyak dan memungkinkan minyak mengalir keluar melalui celah di dalam mesin.

Parameter mesin pemeras minyak sekrup

| Model | 6YL-60 | 6YL-70 | 6YL-80 | 6YL-100 | 6YL-125 |

| Diameter sekrup(mm) | Φ55 | Φ65 | Φ80 | Φ100 | Φ125 |

| Kecepatan rotasi sekrup(r/menit) | 64 | 38 | 35 | 37 | 34 |

| Daya utama(kw) | 2.2 | 3 | 4 | 7.5 | 15 |

| Daya pompa vakum(kw) | 0.75 | 0.75 | 0.55 | 0.75 | 0.75 |

| Daya pemanas(kw) | 0.9 | 1.8 | 2.2 | 3 | 3.75 |

| Kapasitas(kg/jam) | 40-60 | 50-70 | 80-120 | 150-230 | 300-350 |

| Berat(kg) | 240 | 280 | 880 | 1100 | 1400 |

| Ukuran(mm) | 1200*480*1100 | 1400*500*1200 | 1700*110*1600 | 1900*1200*1300 | 2600*1300*2300 |

Keunggulan mesin ekstraksi biji minyak sekrup

- Hasil minyak tinggi: dibandingkan dengan peralatan lama, hasil minyak dapat meningkat 2-3 poin persentase. Untuk setiap 100 pon kacang tanah yang diproses, rata-rata 2-6 pon minyak dapat diproduksi.

- Hemat energi dan ramah lingkungan: hemat 40% listrik dengan output yang sama.

- Menghemat tenaga dan efisiensi tinggi: menghemat 60% tenaga kerja dengan output yang sama, 1-2 orang dapat mengoperasikan.

- Rentang aplikasi yang luas: satu mesin multi-fungsi, dapat memeras lebih dari 30 jenis tanaman minyak (seperti kacang tanah, wijen, bunga matahari, biji kapas, kedelai, dll.).

- Minyak murni: residu disaring dengan vakum, kualitas minyak murni dan sesuai standar karantina kebersihan.

- Ruang kecil: workshop pengepresan hanya membutuhkan 10-20 meter persegi untuk memenuhi kebutuhan produksi.

- Pengendalian suhu cerdas: sistem pengendalian suhu inframerah digunakan untuk secara otomatis mengontrol suhu dan kelembapan pengepresan, molekul minyak langsung dilunakkan dan diaktifkan, dan hasil minyak meningkat secara signifikan.

- Filtrasi berkualitas tinggi: menggunakan perangkat filtrasi presisi multi-tahap untuk meningkatkan tekanan filtrasi minyak dan suhu minyak mentah, kualitas minyak lebih murni dan proses filtrasi lebih cepat.

Petunjuk penggunaan penggiling minyak sekrup

- Periksa pengencang sebelum digunakan untuk memastikan tidak ada yang longgar; putar secara manual pegangan dan pulley untuk memastikan operasi lancar dan tidak ada suara abnormal.

- Isi reduktor dengan minyak 30#. Mesin harus di-grounding dengan baik sebelum dinyalakan.

- Hubungkan mesin ke sumber daya tiga fase empat kawat, dan spindle harus berputar berlawanan arah jarum jam setelah mesin dinyalakan.

- Sesuaikan termostat ke 120°C-160°C (tergantung minyak), nyalakan saklar pemanas mesin utama dan panaskan mesin terlebih dahulu.

- Setelah memasang mesin baru, perlu dilakukan masa break-in selama 4-8 jam: masukkan perlahan-lahan ampas minyak kering dari hopper, dan tekan kembali berulang kali untuk memoles ruang pengepresan.

- Jaga bahan yang dimasukkan secara merata, hindari pecahnya bahan atau terlalu banyak bahan, mesin dimuat secara normal, berjalan lancar, suara ritmis.

- Sebelum mematikan mesin, hentikan pengisian, masukkan sedikit residu ampas, tunggu sampai bahan sisa di ruang pengepresan dikeluarkan, dan matikan mesin setelah tidak ada lagi ampas yang keluar dari outlet ampas.

- Setelah mematikan mesin, putar sekrup pengatur searah jarum jam sebanyak 1-3 putaran, dan akhirnya matikan daya.

Pabrik kami memproduksi jenis lain dari penekan minyak , seperti penekan minyak hidrolik (Mesin Ekstraksi Minyak | Pemeras Minyak Sekrup | Penggiling Minyak Hidrolik ). Jika tertarik, Anda dapat mengisi formulir di sebelah kanan dan memberi tahu kami bahan baku dan kebutuhan spesifik Anda. Kami akan memberi Anda rekomendasi yang tepat untuk membantu bisnis pengepresan minyak Anda berjalan lancar.