Screw Oil Press Machine Peanut Sesame Oilseed Extraction Equipment

Screw Oil Press Machine Peanut Sesame Oilseed Extraction Equipment

Oil extraction equipment | Automatic oil expeller

Features at a Glance

The automatic screw oil press machine is a kind of efficient and energy-saving oil extraction equipment, which is widely used in small and medium-sized oil mills and family workshops with 20%-50% oil conversion rate.

Compared with the traditional oil extraction method, the oil yield of this equipment has been increased by 4% to 6%, and the energy consumption has been reduced by about 60%, which significantly improves the production efficiency and economic benefits.

This series of oil press is easy to operate, covers a small area, and is suitable for hot and cold pressing of various oil crops. It is suitable for more than 30 oilseed crops such as peanut, soybean, sesame, rapeseed, etc. The residual oil rate of dry cake is as low as 0.5%-3.5%, and the production capacity of the single machine covers from 15kg/h to 550kg/h.

According to different production requirements, a variety of models are available to choose from, such as 6YL-60, 6YL-70, 6YL-80, 6YL-100, 6YL-125, etc., to meet the diversified needs of users.

Hot selling screw oil press machine

The automatic screw oil press machine can realize vacuum filtration. Different temperatures can be set according to different materials.

Rotating the handle can adjust the pressure that people require to squeeze the material. The amount of oil squeezed out at a time is also different for different pressures, and the thickness of the oil cake is also different.

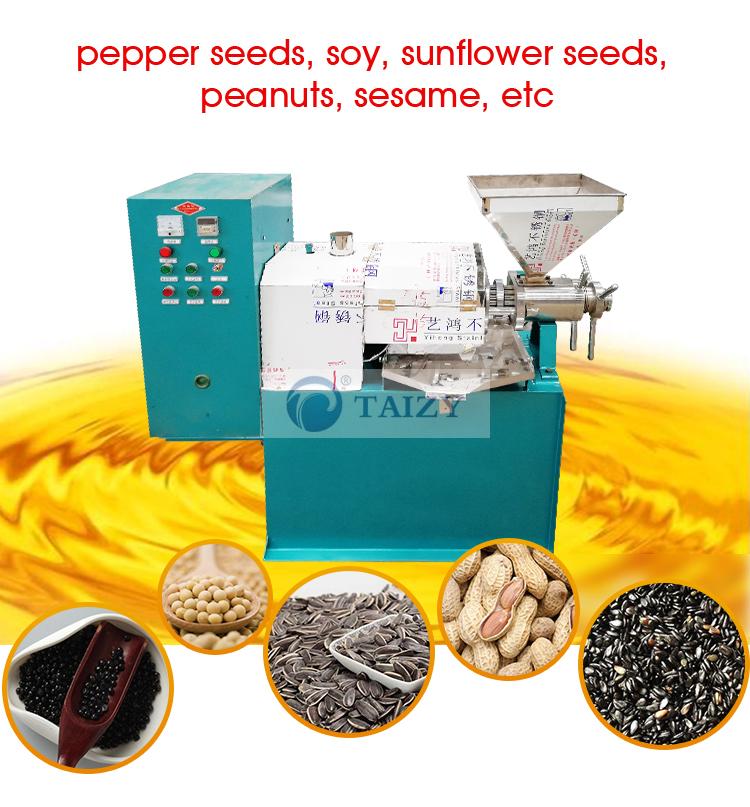

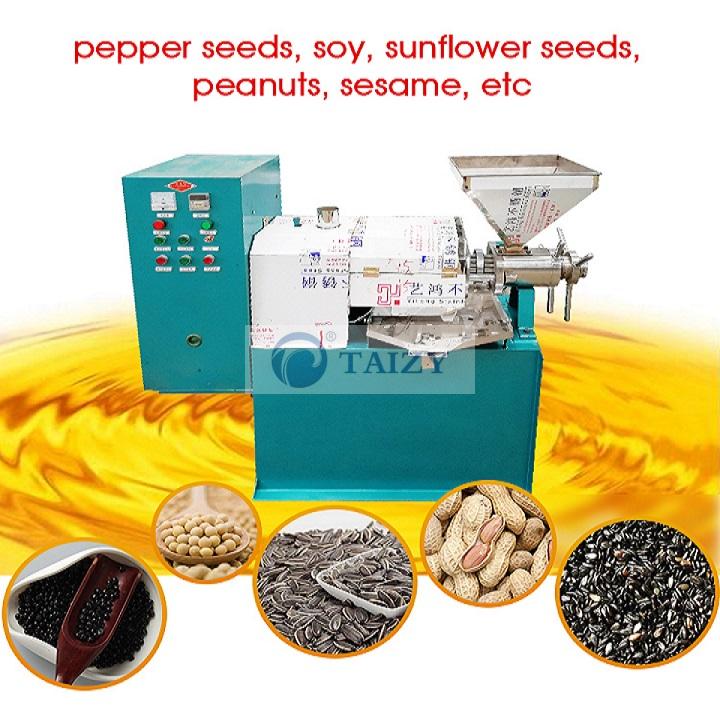

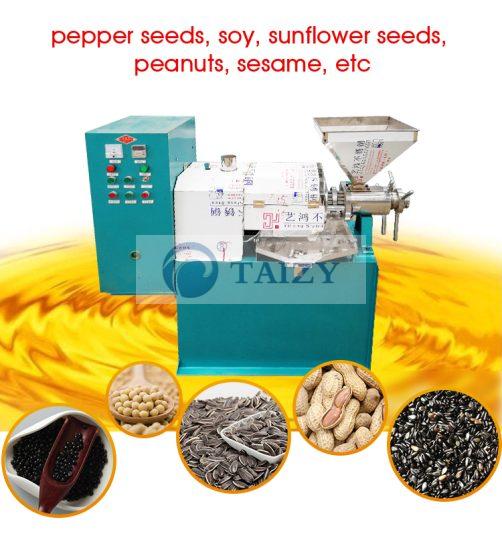

Screw oil expeller applicable materials

Our screw oil press machine is suitable for peanuts, flax, sesame, rapeseed, oil sunflower, cottonseed, soybean, walnut, pepper seed, tung seed, castor, almond, etc.

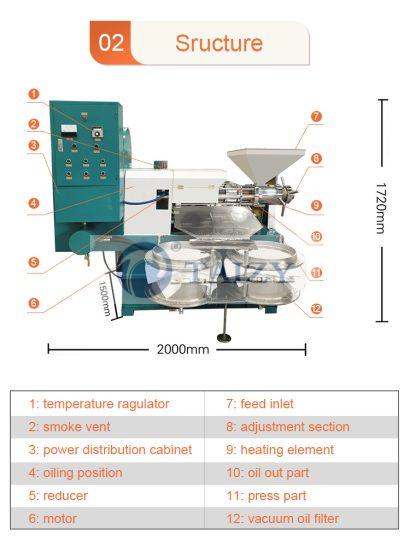

Screw press oil extraction’s structure

The structure of the screw oil press machine includes a temperature regulator, smoke vent, powder distribution cabinet, oiling position, reducer, motor, feed inlet, adjustment section, heating element, oil out part, press part, vacuum oil filter, etc.

Working principle of screw oil extractor

In a screw oil press machine, raw materials enter the press chamber from the hopper. Then, they are pushed inward by the screw for pressing.

The high pressure and friction between the material, screw, and chamber create relative movement and generate heat, aiding in the oil extraction process.

The screw’s increasing diameter and decreasing pitch push the material forward and outward. While frictional heat helps denature proteins, increase plasticity, and reduce viscosity, thereby improving the oil yield and allowing oil to flow out through gaps in the press.

Parameters of screw press oil pressor

| Model | 6YL-60 | 6YL-70 | 6YL-80 | 6YL-100 | 6YL-125 |

| Screw diameter(mm) | Φ55 | Φ65 | Φ80 | Φ100 | Φ125 |

| Screw rotating speed(r/min) | 64 | 38 | 35 | 37 | 34 |

| Main power(kw) | 2.2 | 3 | 4 | 7.5 | 15 |

| Vacuum pump power(kw) | 0.75 | 0.75 | 0.55 | 0.75 | 0.75 |

| Heating power(kw) | 0.9 | 1.8 | 2.2 | 3 | 3.75 |

| Capacity(kg/h) | 40-60 | 50-70 | 80-120 | 150-230 | 300-350 |

| Weight(kg) | 240 | 280 | 880 | 1100 | 1400 |

| Size(mm) | 1200*480*1100 | 1400*500*1200 | 1700*110*1600 | 1900*1200*1300 | 2600*1300*2300 |

Screw oilseed extraction machine advantages

- High oil yield: compared with the old equipment, the oil yield can be increased by 2-3 percentage points. For every 100 pounds of peanuts processed, an average of 2-6 pounds of oil can be produced.

- Energy saving and environmental protection: save 40% of electricity under the same output.

- Save labor and high efficiency: save 60% of labor under the same output, 1-2 people can operate.

- Wide range of application: one machine is multi-purpose, can press more than 30 kinds of oil crops (such as peanut, sesame, sunflower, cottonseed, soybean, etc.).

- Pure oil: the residue is filtered by vacuum, the oil quality is pure and conforms to the hygienic quarantine standard.

- Small floor space: the pressing workshop only needs 10-20 square meters to meet the production demand.

- Intelligent temperature control: an infrared temperature control system is adopted to automatically control the pressing temperature and moisture, the oil molecules are directly softened and activated, and the oil yield is greatly increased.

- High-efficiency filtration: adopting multi-stage precision filtration device to increase oil filtration pressure and crude oil temperature, the oil quality is purer and the filtration speed is fast.

Screw oil mill’s instructions for use

- Check the fasteners before use to make sure there is no looseness; manually turn the handle and pulley to make sure the operation is flexible and no abnormal noise.

- Fill the reducer with 30# oil. The machine must be reliably grounded before starting.

- Connect the machine to three-phase four-wire power supply, and the spindle should be rotated counterclockwise after the machine is turned on.

- Adjust the thermostat to 120°C-160°C (depending on the oil), turn on the heating switch of the main machine and preheat the machine.

- After installing the new machine, it needs to break-in for 4-8 hours: put in the dry oil cake from the hopper slowly, and press it back repeatedly to polish the pressing chamber.

- Keep the feeding material evenly, avoid breaking material or too much material, the machine is loaded normally, running smoothly, sound rhythmic.

- Before stopping the machine, stop feeding, put in a small amount of cake residue, wait until the residual material in the press chamber is discharged, and stop the machine after no more cake comes out of the cake outlet.

- After stopping the machine, turn out the adjusting screw clockwise for 1-3 turns, and finally disconnect the power supply.

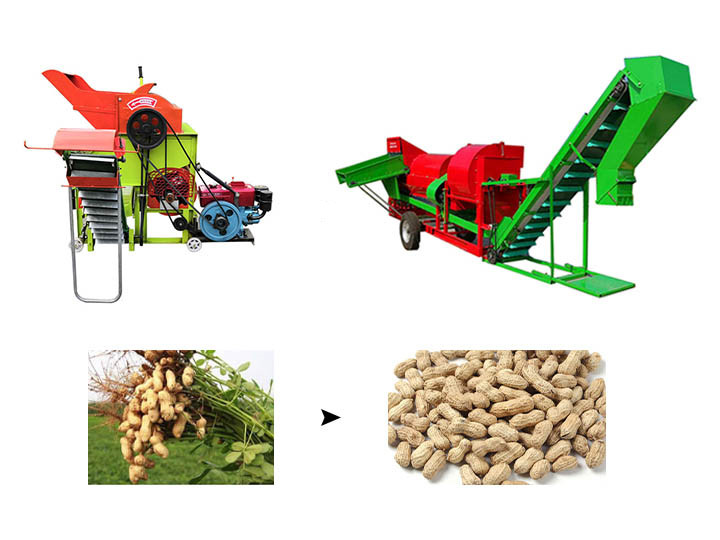

Our factory produces other kinds of oil presses, such as hydraulic oil presses(Oil Extraction Machine |Screw Oil Expeller|Hydraulic Oil Mill). If interested, you can fill in the form on the right and tell us your raw material and specific needs. We will give you the right recommendation to help your oil-pressing business run smoothly.