Oil Extraction Machine |Screw Oil Expeller|Hydraulic Oil Mill

Oil Extraction Machine |Screw Oil Expeller|Hydraulic Oil Mill

Hydraulic oil press machine/Oilseed processing machinery

Features at a Glance

An oil extraction machine refers to a machine that squeezes grease out of oil using external mechanical force. It squeezes out grease by increasing the temperature and activating oil molecules. Now the common oil extraction machine on the market mainly includes two types: screw oil expeller and hydraulic oil mill. The most common oil pressing processes are hot pressing and cold pressing.

Introduction to oil extraction machine

Introduction to screw oil expeller

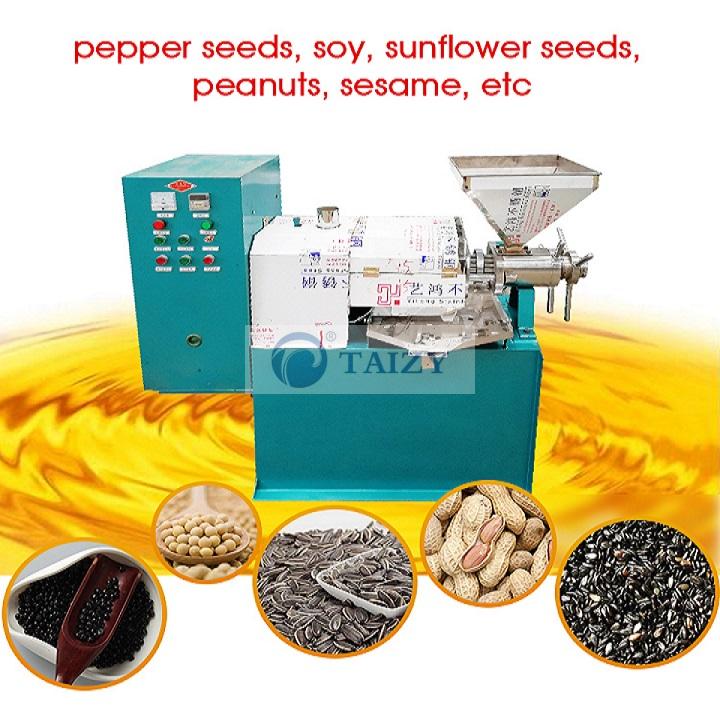

As a common oil pressing equipment, a screw oil expeller can be used for continuous production, with a large processing capacity and high oil. You can use it for cold pressing and hot pressing.

It is suitable for squeezing peanuts, sesame seeds, rapeseeds, tea seeds, soybeans, sunflower seeds, cottonseeds, and other oils. In addition to squeezing edible oil, the oil pressing equipment is also suitable for squeezing spice oil, medicinal oil, etc.

Introduction to hydraulic oil mill

The hydraulic oil mill is professional equipment for pressing sesame, rapeseed, sunflower, and other high-oil crops.

The working principle of the oil extraction machine

The working principle of the screw oil expeller

Generally speaking, due to the effect of promoting the rotation of the screw shaft in the pressing chamber, the material continuously presses forward. At the same time, the pitch on the screw shaft shortens, the diameter of the root circle increases, and the inner diameter of the press chamber decreases.

The volume of the squeezing chamber keeps shrinking, thereby exerting a squeezing effect on the squeezing material. After compressing the material, the grease is squeezed out from the gap of the cage. At the same time, the end of the squeezing chamber discharges the squeezed material of the cake.

When the squeezed oil flows into the oil filter through the oil pan, negative pressure is formed in the barrel. The oil passes through the filter cloth and is drawn into the oil filter barrel. The oil residue is isolated on the filter cloth. What you get at this time is pure oil.

Working principle of hydraulic oil mill

The hydraulic oil mill uses Pascal’s mechanics. Use the liquid as the medium for pressure transmission. This generates work pressure. As a result, the oil is squeezed into the pressing chamber. Then, it can squeeze out the oil.

Structure of oil extraction machine

The structure of the screw oil expeller

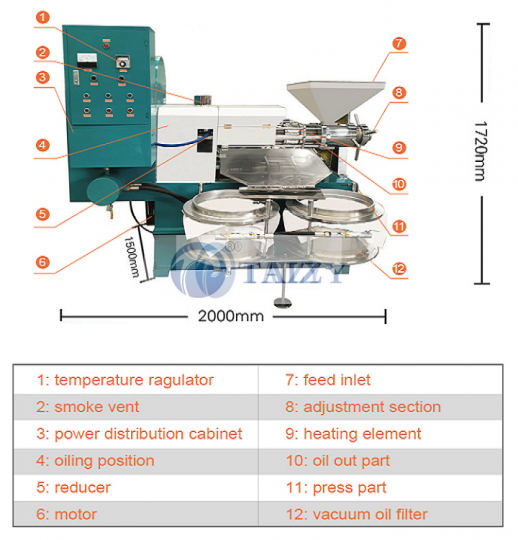

This series of units is mainly composed of five parts: the electrical control part, the heating and pressing part, the adjustment part, the transmission part, and the vacuum oil filter.

1) The electrical control part includes an air switch, an AC contactor, a temperature controller, and an automatic circuit protection device.

2) Heating and pressing part consists of a heater, a screw press, a machine body device, etc.

3) The transmission part consists of the main shaft, a reduction box, a pulley, and a motor wheel.

4) Speed regulating part includes adjusting the screw, adjusting the nut, handle, lock nut, and so on.

5. Vacuum oil filter parts have a vacuum pump, oil filter cartridge pipeline, etc.

Structure of hydraulic oil mill

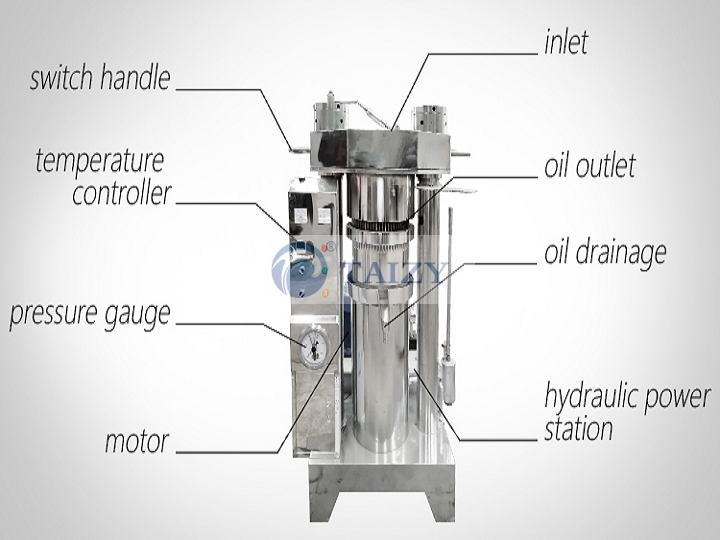

The oil extraction machine mainly consists of three parts: main body, transmission hydraulic pressure, and electrical control.

- Main body: It has the bottom plate, column, upper top plate, press assembly, oil pan, nut, and other parts. It is one of the main parts of the whole machine. The oil is in the press assembly and is used by the oil cylinder assembly. The force pushes upwards. And the oil flows down from the cracks in the squeezing stream. Then passes through the oil pan to the oil storage barrel.

- Hydraulic transmission: This is the main working power source for this oil extraction machine to produce a high oil rate. It has the drive shaft, worm gear, worm, gear pump, high-pressure pump, relief valve, manual valve, cylinder assembly, pipe joints, and other parts. This machine uses the world’s most advanced hydraulic pumping station. Which has lower speed, higher oil pressure, and high-temperature resistance. And no cooling device when the oil temperature is above 65 degrees, and it can work continuously.

- Electrical control: This is the advanced point of this oil extraction machine. It consists of components such as a motor, a voltmeter, a temperature control gauge, a pressure gauge, and power supply insurance.

Advantages of oil extraction machine

1. High oil output rate: The oil extraction machine adopts directional pressure bearing, multi-stage propulsion, and one-time squeezing. So the oil output rate improves.

2. Large production volume: It strengthened the feeding system. And increased the advancement speed. Thus it greatly improved work efficiency.

3. Automatic temperature control: electronic program control, scientific heating, and automatic control of pressing temperature.

4. Automatic oil filtering: Using the principle of negative air pressure, using vacuum splitter technology, built-in vacuum splitter. So it can separate the oil and residue.

5. Safe and convenient: exquisite structure, less space occupation; transmission system adopts fully enclosed protection, safe and convenient operation.

6. Beautiful and generous: The watch is a new-type material electrostatic spraying, with strong adhesion, grease resistance, and high-temperature resistance. It is beautiful and easy to clean to ensure hygiene.

7. Durable: It matches high-quality wear-resistant steel and anti-fatigue castings scientifically. With stable performance, ensuring that the equipment can work continuously for a long time and is durable.

8. One machine with multiple functions: In addition to squeezing edible oil, this oil extraction machine is also suitable for squeezing spice oil, medicinal oil, and other oils, with a wide range of applications.

Parameters of oil extraction machine

screw oil expeller parameters

| Model | Power supply | Snail diameter | capacity | Machine weight |

| ZY-70 | 220/380V | 70mm | 50~70kg/h | 350kg |

| ZY-80 | 380V | 80mm | 100~120kg/h | 750kg |

| ZY-100 | 380V | 100mm | 150~200kg/h | 900kg |

| ZY-120 | 380V | 120mm | 200~300kg/h | 1300kg |

| ZY-140 | 380V | 140mm | 400~500kg/h | 1500kg |

Hydraulic oil mill parameters

| Model | 6YZ-180 | 6YZ-230 | 6YZ-260 | 6YZ-320 |

| Feeding Diameter | 180mm | 230mm | 260mm | 320mm |

| Heating Range | 2KW | 2KW | 2KW | 2KW |

| Heating coil control temperature | 70-100 | 70-100 | 70-100 | 70-100 |

| Pressure | 55Mpa | 55Mpa | 55Mpa | 55Mpa |

| Pressing Time | 7 min | 8 min | 10 min | 10min |

| Capacity(Per time) | 2-3kg | 7-8kg | 10-12kg | 15kg |

| Capacity | 30kg/h | 50kg/h | 60kg/h | 90kg/h |

| Dimension | 500*650*1050 | 600*850*1360 | 650*900*1450 | 800*1100*1550 |

| Weight | 750kg | 1050kg | 1400kg | 2000kg |

The difference between cold pressing and hot pressing

hot pressing

Most of the vegetable oils we eat in our lives are hot-pressed oils. That is, the oil is cleaned and crushed before being subjected to high-temperature heating treatment. This causes a series of changes in the oil: destroying oil cells, promoting protein denaturation, reducing oil viscosity, etc.

Therefore, the hot-squeezed oil rate will be higher. However, the crude oil squeezed from the oil after high-temperature treatment has a strong taste, darker color, and higher acid value. Therefore, the crude oil must be refined before consumption.

At the same time, high-temperature squeezing of oil causes the biologically active substances in the oil to be greatly lost during the squeezing process, which will cause a waste of resources.

cold pressing

Cold-pressed oil refers to the oil that presses without heating or at a low temperature. So this kind of oil has a lower temperature and a lower acid value. Generally, it does not need refining, just needs precipitation and filtration.

However, the general cold pressing process will reduce the oil yield compared to the hot pressing process. However, cold-pressed oil retains the natural flavor and color of the oil and completely preserves the physiologically active substances in the oil.

The key factors affecting the oil output of the oil extraction machine

- The raw materials are not clean enough, and sand and impurities enter the press chamber.

- Raw material moisture is inappropriate. (Adjust the moisture of the raw materials) The raw materials are too wet or too dry, damp and moldy, the grains are not full, and there are too many impurities. Need to re-clean the oil, or adjust the oil moisture.

- The speed of the screw shaft is too high or too low, and adjust the speed until it meets the requirements.

- When the cake is too thin or too thick, adjust the thickness of the cake or the oil output.

- If the oil residue blocks the drain seam, remove it. And adjust the tightness of the sliver according to the level of oil content.

- In the initial stage of squeezing, the temperature of the press chamber is too low, so increase the temperature.

- If there are worn-out parts, replace the worn parts.

- If the screw shaft is polished, replace it.

- Striped and round discharge oil eyes are small, and the oil is not smooth.

- The screw shaft or the cake outlet is not smooth, which affects the feeding and the cake. You can polish it with a grinding wheel, or you can mix materials with high friction coefficient such as chaff into the cake, add proper water, turn on the oil extraction machine, slowly feed and squeeze, and polish the cake outlet.

Several common oil squeezing methods

Rapeseed

First, heat the oil extraction machine to 110-140C. Roast the rapeseed in the pot. When the rapeseed in the pot emits green smoke, stir-fry the rapeseed over low heat until the rapeseed is crushed and turned into a deep yellow color, and then take it out of the pot.

Cool down to about 60 degrees and put it in the oil press. The oil quality of the refined oil is yellow, and the cakes are large or long strips of black and yellow.

Peanuts

Raise the temperature of the oil extraction machine to about 180 degrees, fry the peanuts in the pan until slightly yellow, and squeeze it while hot. The oil is yellowish-white, and the cake is large or long.

Soybean

Raise the temperature of the machine to about 140°C, fry until bursting and edible, and lower it out of the pan to about 60°C and squeeze the cake.

Sesame

The oil extraction machine heats up to 130-170 degrees and stirs the sesame seeds into the pot. And fry them until they become round and swell. After rolling, they will become yellow and oily. Then quickly raise it several times to eliminate the black smoke and then squeeze it. The oil is reddish-yellow, and the cake is large or long.

Cottonseed kernels

Stir-fry the oil until light golden brown before pressing, the temperature is 120-130 degrees. And the cake thickness is 1-1.5mm.

Instructions for use

How to start the machine

1. Before use, you must read the instruction manual carefully and be familiar with the performance characteristics and operation methods of this oil extraction machine.

2. Before starting the machine, carry out a comprehensive inspection. Do not loosen all fasteners, the handle can turn flexibly, and turn the pulley by hand. Ensure the running parts are normal and there is no abnormal noise. Then fill the gearbox with No. 20 mechanical oil.

3. Loosen the lock nut and turn the adjustment screw counterclockwise (turn the adjustment handle counterclockwise to narrow the gap between the cakes, and turn the adjustment handle clockwise to widen the gap between the cakes) so that the conical surface of the squeezed screw presses against the cake ring Then turn out the adjusting screw clockwise (twist out 3-5 turns), and then tighten the nut, ready to start the oil extraction machine.

4. The oil extraction machine connects a three-phase four-wire power supply. After turning on the power, the main shaft should rotate counterclockwise. In any case, the machine must have a good grounding device, otherwise do not turn on it.

5. At first, adjust the temperature controller to the required temperature of 120℃—160℃ (depending on the oil). Then turn on the heating switch to the heating position of the host to heat the machine.

At this time, the green light on the temperature controller is on and the red light is off. When the machine temperature rises to the set temperature, the red light is on and the green light is off.

The temperature of the machine automatically controls and maintains at the set temperature. When the temperature is low in winter, turn on the heating switch to the full heating position of the host. Increase the temperature of the oil pan to facilitate oil retention.

About installing a new machine

1. After installing the new oil extraction machine, mill it for 4-8 hours. The method is to use the cake material that has been squeezed to dry the oil and slowly feed it from the hopper. Next, repeatedly press back to polish the press chamber.

But, do not pour the material directly into the hopper when starting to grind. It is advisable to grab and feed by hand to prevent the squeezing screw from jamming. If the feed is too strong, there is an abnormal noise in the press chamber, or the press screw shaft sticks, stop it immediately to eliminate the obstruction. Or start the grinding after reassembly.

2. During normal oil extraction, the feed must be kept uniform. So do not run too much or too little or cut off the material. At this time, the load of the oil extraction machine is normal, the operation is stable, and the sound is rhythmic.

The cake output is smooth, the low-pressure section is free of slag, and there is a small amount of oil slag in the high-pressure section. But the proportion of residue in the oil is not more than 10%. The blue smoke coming out of the cake outlet discharged from the smoking pipe through the shield.

What’s more, spread out the squeezed hot cake in time, and don’t rush to pile or ship, otherwise, it will produce natural phenomena. When the continuous working time is long and the temperature of the machine is too high, take cooling measures such as an electric fan and blower.

3. When the squeezed oil flows into the oil filter, press the vacuum pump button. Then the vacuum pump starts to run, it will draw out the air in the oil filter.

Thus, it forms an internal pressure in the oil filter barrel, the oil on it naturally draws into the oil filter, and the oil residue isolates on the filter cloth. After pumping the squeezed oil, open the valve on the oil filter and stop the vacuum pump.

And dry residue forms on the filter cloth. Then use a spatula to scrape it off. Finally, discharge the oil in the oil filter from the bottom valve.

Shut down

First, stop feeding before shutting down, and then put in a small number of cake crumbs. Then wait until it exhausts the remaining material in the press chamber. And the cake outlet will no longer deliver cakes before shutting down. After stopping, turn the adjusting screw clockwise out 1-3 times. And then disconnect the power supply.

Besides this machine, we also have other types of oil presses to choose from, such as Screw Peanut Sesame Oil Press Machine Press Oil Extraction.

FAQ

Insufficient hydraulic pump pressure

Reason

①The oil outlet valve is dirty or has poor contact; ②The oil return valve on the press has poor contact with the valve seat or is untightened, resulting in oil return; ③The wear gap between the small piston and the pump body is too large.

Solution

① disassemble and grind to make it close; ② Grind the oil inlet and outlet valve plugs and valve seats on the press to make them close or tighten the plugs; ③ Replace the pump with a new one.

The hydraulic pump can’t get oil

Reason

①The oil filter blocks; ②the oil has been used for too long, and there are sediments attached to the fuel inlet valve, which makes the throttle not tight; ③The oil in the fuel tank is too thick or solidified due to weather; ④The amount of oil in the fuel tank is insufficient; ⑤Hydraulic There is no vacuum in the pump.

Solution

①Clean the oil filter screen; ②Replace new oil or discharge old oil; Filter and clean the oil inlet valve, and grind it to make it tight; ③Replace thin oil, increase the room temperature in cold weather; ④Add enough oil to the fuel tank Quantity; ⑤ Pull out the small piston, inject the oil and press it again.

The pointer of the pressure gauge cannot be maintained and drops rapidly

Reason

①The safety valve is unsealing; ②The oil inlet and outlet valve screw plugs and the steel ball are in poor contact; ③The oil pipe joints and the hydraulic cylinder screw plugs are not tightened with the hydraulic cylinder oil inlet hole; ④The three-way oil return valve is in poor contact with the steel ball.

Solution

① Grind the safety valve to make it tight; ② Grind the oil inlet and outlet valves to make it tight; ③ Tighten the oil pipe joints and hydraulic cylinder plugs; ④ Grind the oil return valve.