Cow milking machine | Goat milking machine | Goat milker

Cow milking machine | Goat milking machine | Goat milker

Automated milking machine/Milk machine

Features at a Glance

The cow milking machine can be used to milk cows, sheep, and goats. Our milking machines for goats and cows are divided into piston pump type milking machines and vacuum pump-type milking machines. The milking speed of the vacuum milking machine is very fast, and the milk expressed is relatively clean and hygienic.

Types of cow milking machine

Our cow milking equipment has a single-barrel milking machine and an exquisite double-barrel goat milking machine. The milk barrel volume has a 25-liter milk barrel with stainless steel and a 32-liter transparent milk barrel. The power can be equipped with electric motors and gasoline engines, and the voltage of the electric motors can be customized.

Piston pump type milking machine structure

Our portable milk machine for cows is mainly composed of a supporting frame, milk bucket, milk cup group, regulating valve, milk collector, pipeline, vacuum gauge, piston pump, transmission device, motor, and working lamp.

Cow milking machine technical parameters

| Model | HL-JN01 | HL-JN02 |

| Vacuum | 50 kPa | 50 kPa |

| Vacuum pump | 250L/MIN | 250L/MIN |

| Voltage | 220v/50HZ(Motor can be customized) | 220/50Hz((Motor can be customized)) |

| Power | 0.75KW | 1.1kw |

| Stainless steel milking bucket | 25L(transparent milk bucket) | 25L(transparent milk bucket) |

| Capacity | 10-12 cows/hour | 20-24 cows/hour |

| Milking time | 5-6mintue/cow | 5-6mintue/cow |

| Pulse rate | 60:40 | 60:40 |

| Suitable | Cows, goats (can replace the milking cup) | Cows, goats (can replace the milking cup) |

| Machine weight | 90kg | 100kg |

| Packing size(LxWxH) | 800*650*980mm | 800x720x980mm |

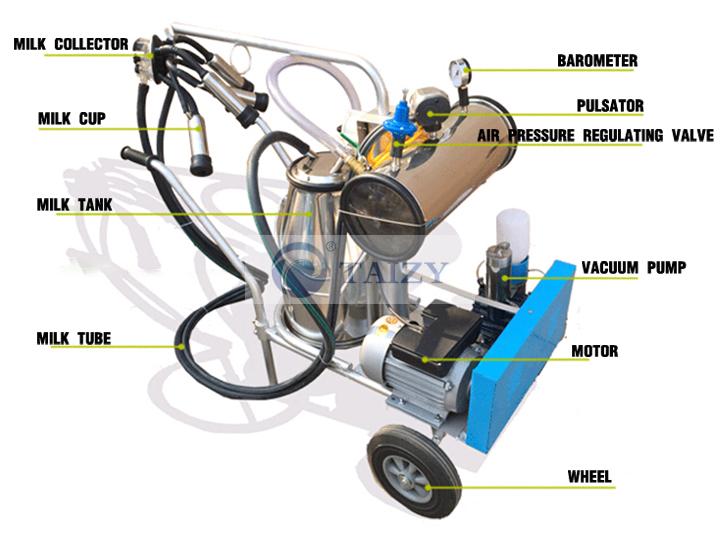

Composition of vacuum cow milking machine

The vacuum pump for the milking cow support frame has a pressure regulating valve, milking barrel, silencer, pulsator, milk collector, vacuum gauge, air pipe, milk liner, milk pipe, and vacuum pump.

This vacuum pump for goat milking equipment adopts a rotary vane vacuum pump, a direct transmission, compact and reasonable structure, with an automatic lubrication device to ensure trouble-free operation.

Technical Parameters

| Model | HL-JN04 | HL-JN05 |

| Name | Single barrel piston milking machine | Double barrel piston milking machine |

| Vacuum | 50 kPa | 50 kPa |

| Vacuum pump | 250L/MIN | 250L/MIN |

| Voltage | 220v/50HZ(Motor can be customized) | 220/50Hz((Motor can be customized)) |

| Power | 0.55KW | 0.75KW |

| Stainless steel milking bucket | 25L(transparent milk bucket) | 25L(transparent milk bucket) |

| Capacity | 10-12 cows/hour | 20-24 cows/hour |

| Milking time | 5-6mintue/cow | 5-6mintue/cow |

| Pulse rate | 60:40 | 60:40 |

| Suitable | Cows, goats (can replace the milking cup) | Cows, goats (can replace the milking cup) |

| Machine weight | 68kg | 98kg |

| Packing size(LxWxH) | 800x620x1000mm | 800x650x1000mm |

A stainless steel vacuum tank is used, and goat milk is pumped into the vacuum tank through a rubber tube. The vacuum tank is equipped with a vacuum regulator and a pulsator. The milk bucket is made of stainless steel and is equipped with a rubber sealing ring to form a sealed container when working.

The milking cup is assembled with an automatic switch, which is an important measure to protect the breast, and is equipped with a suction stop valve. Using an imported pulsator, its pulsating waveform is extremely stable and reliable.

Working on cow milking machine

Check the milking pressure and run it for 2-3 minutes after starting the machine. There should be no sticking or abnormal sound in all moving parts. Then turn the milk cup group upside-down (that is, the connection ports of the milk collector face up and the milk cup mouth down), and the pointer of the vacuum gauge should reach 0.04-0.045 Mpa.

When the vacuum is too high or too low, adjust the regulating valve (clockwise) The vacuum degree of rotation increases, and the degree of vacuum decreases when rotating counterclockwise) to make it reach the required milking pressure before the milking work can be performed. This is very important when the milking components are operated.

Installation of milk cup

The milker should stand on the side of the cow with the milking cup set upside down in his left hand (the connecting pipes of the milk collector are facing upwards, and the teat cups are facing down), and place them under the nipples. Correspondingly bend the short tubes one by one so that the atmosphere cannot enter), quickly put them on the nipple, stretch the short tubes, and the vacuum will start sucking the nipple

Milk flow control

Milking should be carried out under a normal working vacuum (generally no more than 0.05Mpa). When the milk flow is low, the breast can be massaged by hand. Once the milk flow stops, the milk collector should be pressed by hand for 5-10 seconds to continue milking.

Then hold the breast collector with one hand, and press the opening of the teat cup on the breast with the other hand to allow the atmosphere to enter and quickly move the teat cups one by one from different directions.

Other conditions

Cows and sheep that have never used a cow milking machine may have lower milk production in the first few days, or even drop the milk cup. Never use manual milking at this time, otherwise it is difficult for cows and sheep to accept mechanical milking.

Put the milking machine in the cowshed a few days before the first use, and let them get used to the noise of the machine and the things on the cow milking machine, for about 2-4 days. The cow will gradually get used to the milking machine and the milk production will return to normal.

Advantages of vacuum pump milking machine

- Low noise, simple structure, flexible and convenient operation, stable work, high milking efficiency, alternate milking.

- Equipped with a pulsator, milking is gentle, does not damage the nipples, and helps to increase the milk production of the dairy sheep.

- The vacuum mobile sheep milking equipment has the advantages of stable performance, large effective storage of vacuum tanks, low noise, and simple operation.

- The milker machine works in a horizontal state and is pushed to the side of the milk goat for milking. It can also be connected as a vacuum source for pipe milking.

Packing and shipping

After customers place an order from us, we will ship them immediately, because our various types of cow milking machines are in stock. We use wooden box packaging, so many exported machines have received unanimous praise from customers. Because the customer received the machine in good condition.