Mashine ya uvunaji wa uvunaji wa mazao ya ngano

Mashine ya uvunaji wa uvunaji wa mazao ya ngano

Mvunaji wa ngano ya mchele | Kivuna ngano na kipura

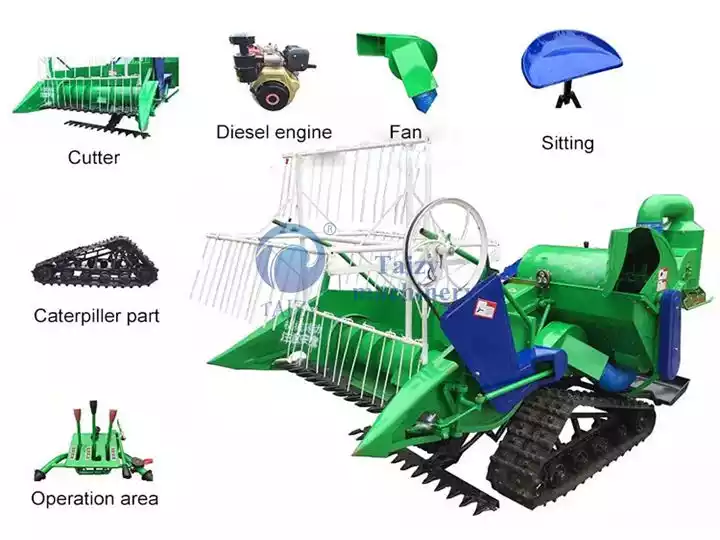

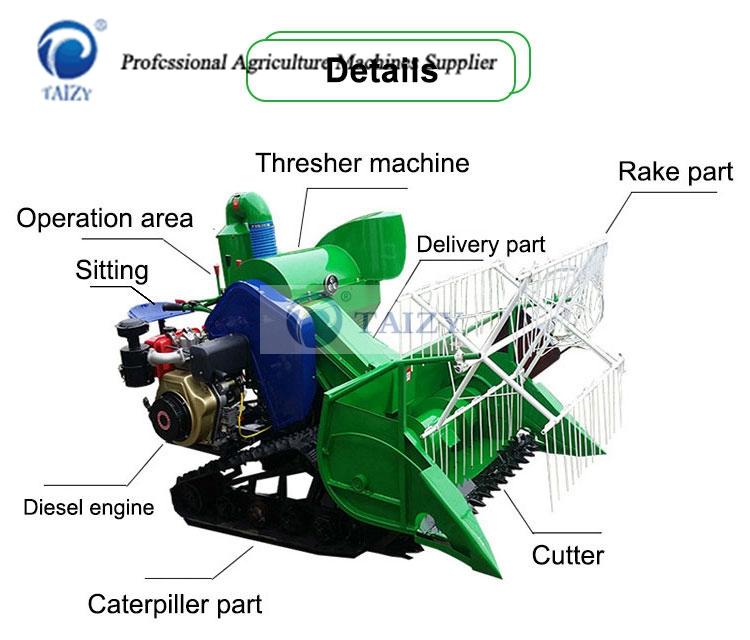

Vipengele kwa Mtazamo

Katika njia ya jadi ya kuvuna mchele, majukumu tofauti ya uvunaji wa mwongozo na kupindukia sio tu yanahitaji kiwango kikubwa cha kazi lakini pia husababisha upotezaji wa nafaka wa karibu 10% hadi 15%.

Ingiza mashine ndogo ya pamoja ya wavunaji wa mpunga, ambayo inachanganya kwa busara michakato ya kuvuna na kupuria kuwa operesheni moja bora. Kwa uwezo wa kufunika 50 hadi 80 MU kwa siku moja na kiwango cha upotezaji wa 1.5% tu au chini, inatoa suluhisho kamili kwa kilimo cha kisasa, ikikuchukua bila mshono kutoka shamba hadi silo ya nafaka.

Sehemu bora ni kwamba, hautalazimika kuwekeza katika mashine mbili tofauti - wavunaji mdogo wa pamoja na thresher. Aina hii ya mashine inaweza kukusaidia kuokoa pesa na nguvu zote. Katika nakala hii, tutachunguza aina mbili tofauti za mashine za uvunaji wa mchele.

Andika moja

Mashine hii ndogo ya pamoja ya wavunaji imeundwa kwa mchele na ngano. Inavuna kwa ufanisi mazao kwa kuikata moja kwa moja kutoka shambani, wakati pia inashughulikia kunyoa, kutenganisha majani, na kuondoa uchafu wote kwa njia moja.

Kwa maneno rahisi, mashine hii sio tu hukata mchele au ngano lakini pia inazizidi, ikikupa kernels safi mwisho. Pamoja, inajivunia kiwango cha chini cha kuvunjika kwa kernel ya 1.5% tu na kiwango cha upotezaji wa mchele wa 2%.

Kigezo cha kiufundi cha kivunaji kidogo kilichojumuishwa

| Mfano | 4LZ-0.8(Nyimbo) |

| Muunganisho/Hifadhi | Moja, shimoni, Mvutano |

| Hali ya kuanza | Kuanza umeme |

| Taa | 12V/100W |

| Kupoa | Upoezaji wa hewa |

| Uzito | 450 kg |

| Vipimo | 2700*1420*1350 mm |

| Mfano wa injini | 188 F |

| Injini ya dizeli | Silinda moja, mlalo, maji ya kuyeyuka, sindano ya moja kwa moja |

| Nguvu iliyokadiriwa | 13.5 Hp |

| Imekadiriwa kasi ya injini | 3600 r/dak |

| Matumizi ya mafuta | 20 kg/hm2 |

| Kasi ya kazi ya kinadharia | 2.56 (gia ya pili) |

| Tija | 400-1000m2/h |

| Kiwango cha kuvunjika | 1.5% |

| Kiwango cha upotezaji wa mchele | 2% |

| Kiwango cha upotezaji wa ngano | 3.5% |

| Imekadiriwa upana wa kukata | 1200 mm |

| Kibali kidogo cha ardhi | 180 mm |

| Kiwavi | Urefu 800 *Upana 250 mm |

| Ukubwa wa tairi | 5.00-12 |

Kushughulika na mvunaji mdogo wa pamoja

- Mashine ya wavunaji wa mchele inapaswa kwenda shambani moja kwa moja, ambayo inaweza kuboresha ufanisi wa kufanya kazi na kuzuia kupoteza mazao.

- Mtumiaji anatakiwa kudhibiti kasi ya mashine ya kuvuna ngano kulingana na urefu, unyevunyevu wa mazao na unyevu wa shambani. Kupunguza kasi kwa mazao ya juu na kuongeza kasi kwa mashamba kavu.

Manufaa ya wavunaji wa mchele

- Teknolojia ya juu ya kupuria ili kuhakikisha punje safi na utengano kamili.

- Pata ngoma ya tatu-kwa-moja yenye, mzigo mdogo, na kiwango cha chini cha kukatika.

- Bandari pana ya kulisha: malighafi inaweza kuwekwa kwenye mashine vizuri bila kizuizi chochote.

- Usafirishaji mpana zaidi wa kuinua: hurahisisha kufikisha mazao.

- Mashine yetu ya pamoja ya kuvuna mpunga ina muundo unaofaa, kutegemewa kwa hali ya juu, matengenezo rahisi na gharama ya chini.

- Kiwango cha juu cha kupura. Kiwango cha kupura ni zaidi ya 95%.

- Watu wanaweza kukaa kwenye mashine kufanya kazi, kuokoa muda na nishati.

Aina mbili

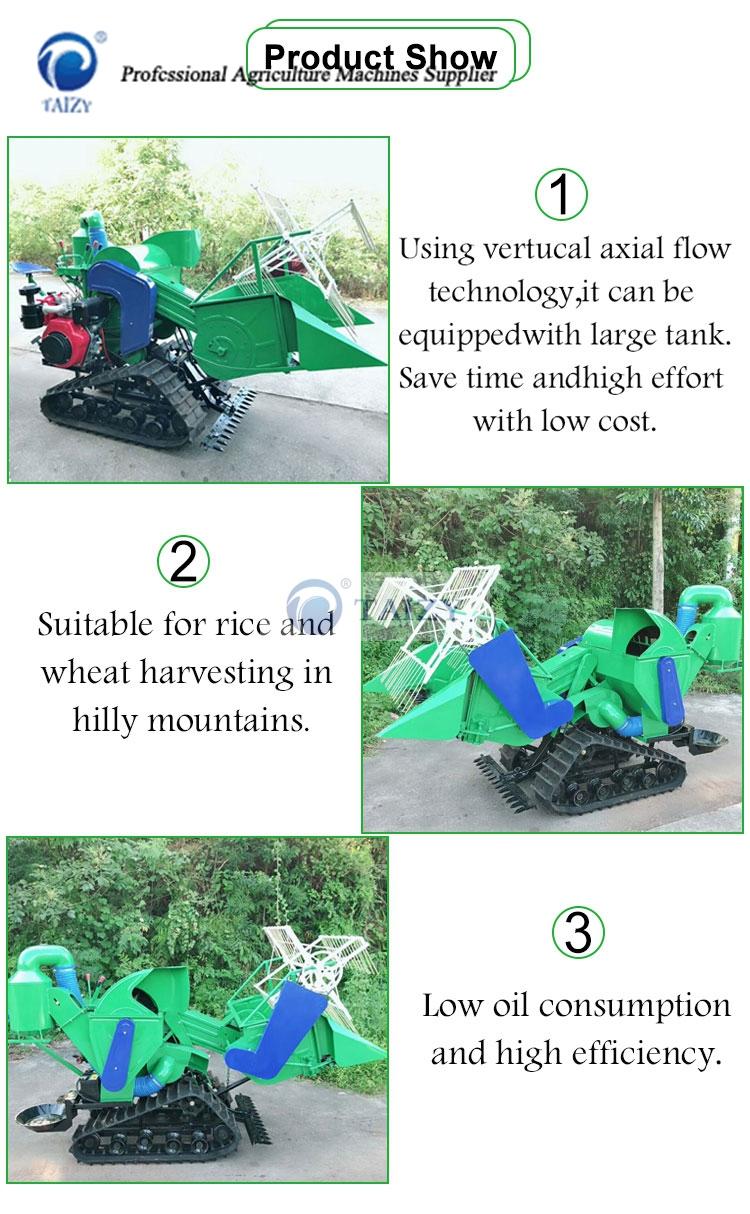

Mvunaji mdogo wa pamoja wa kujisukuma umeundwa kushughulikia kutembea, kuvuna, kusafisha, na kupindukia yote kwenye mashine moja, inayoendeshwa na injini ya dizeli. Inaruhusu waendeshaji kukaa raha wakati wa kufanya kazi, na kuifanya iwe rahisi sana kwa wakulima.

Wavunaji huu hutoa ujanja bora, harakati rahisi, na ufanisi wa kuvutia wa uzalishaji. Baada ya kuvuna, mazao hulishwa ndani ya ngoma ya kupuria, ambayo husaidia kuokoa muda na kazi. Uwezo wake wa juu na kiwango cha chini cha upotezaji ni kati ya faida zake kubwa.

| mfano | TZY-100A |

| aina | Aina ya wapanda farasi (watu wanaweza kukaa) |

| motor | 9.2kw |

| injini | 12.5Hp injini ya dizeli |

| kukata-upana | 120cm |

| kukata-urefu | 12-75cm |

| kiwango cha kuvunjika | <5% |

| maudhui ya taka | <7% |

| uwezo | 1000m³/saa |

| ukubwa | 2600*1340*1540mm |

| uzito | 450kg |

Kuzingatia mashine ya kuvuna mchele

- Hakikisha kusoma mwongozo wa bidhaa kwa uangalifu kabla ya matumizi. Muundo wa kivuna ngano ni mgumu, ingawa ubora wa mashine ni mzuri sana, bado unahitaji kujua muundo wa ndani na kufuata utangulizi ili kufanya kazi. Vinginevyo, mashine ndogo ya kuvuna iliyojumuishwa itakabiliwa na kushindwa.

- Masharti ya mazao yanayovunwa yanatofautiana sana kama vile aina ya mazao, ukomavu, unyevunyevu, mavuno na urefu wa mazao. Kwa hivyo, taratibu zinazofaa za mashine zinapaswa kurekebishwa kwa wakati ili kuhakikisha utendaji mzuri.

- Kifaa cha kinga kilichowekwa kwenye kivuna mchele ni kulinda usalama wa opereta. Kwa hiyo, haiwezi kutenganishwa wakati wa kufanya kazi. Ikiwa imetenganishwa wakati wa matengenezo, mtumiaji anapaswa kusakinisha tena ili kuepuka ajali.

- Kivunaji kinapaswa kukaguliwa na kudumishwa mara kwa mara kama vile kuangalia ikiwa hakina mafuta ya kulainisha au maji, kulegeza skrubu na sauti zisizo za kawaida, n.k.

- Sehemu zote za mashine ya kuvuna ngano zimeundwa ili kuratibiwa na haziwezi kurekebishwa kwa mapenzi.

Faida za mvunaji mdogo wa mchele pamoja

- Uvunjaji mdogo umechelewa. Ni 5% pekee na unaweza kupata kokwa safi na safi.

- Uwezo wa juu. Kivunaji hiki cha pamoja kina uwezo wa juu (1000m³/h) ikilinganishwa na wavunaji wengine.

- Urefu wa kukata unaweza kubadilishwa (12-75cm).

- Uendeshaji rahisi. Mtu mmoja tu anaweza kumaliza michakato yote.

- Vitendaji vingi. Inaweza kuvuna mchele na ngano kwanza na kisha kuzipura ili kupata punje, jambo ambalo huokoa wakati na nishati.

| Kutofanya kazi vizuri | Sababu | Suluhisho |

| Kata imezuiwa. | 1. Nyasi na matope kwenye mkataji. | 1. Acha na vizuizi wazi. |

| 2. Pengo la blade ni kubwa sana. | 2. Kurekebisha kibali cha blade. | |

| 3. Kiasi cha mazao ni kupita kiasi. | 3. kupunguza upana wa kuvuna. | |

| 4. Uharibifu wa blade. | 4. Rekebisha au ubadilishe. | |

| Punguza kiasi cha mazao ya kulisha, na ufanyie kazi na koo la kati na kubwa. | 1. Mazao ni mafupi kuliko 55 cm. | 1. Jaribu kupunguza urefu wa makapi. |

| 2. Rack ya kusafirisha rack imeharibiwa. | 2. Kukarabati au kuchukua nafasi. | |

| Rola ya kupuria imezuiwa. | 1. Kiasi cha kulisha ni kikubwa au kisicho sawa. | 1. Dhibiti mkataji ili kukata mazao sawasawa wakati wa operesheni. |

| 2. Kasi ya ngoma ni ndogo. | 2. Kufanya kazi na koo la kati na kubwa | |

| 3. Shina ni mvua sana, na mazao ni ya juu sana. | 3. Chagua mazao makavu ya kuvuna na kuongeza urefu wa makapi. | |

| 4. Sahani ya mwongozo imetengwa au imevaliwa. | 4. Rekebisha au ubadilishe. | |

| Duka la kernel limezuiwa. | 1. Sehemu ya kernel imejaa, na chombo cha kernel hakibadilishwa kwa wakati. | 1. Badilisha chombo kwa wakati. |

| 2. Shina ni mvua, na nafaka ina magugu. | Kurekebisha urefu wa cutter. | |

| Kichwa cha mazao huanguka chini ya shamba. | Urefu wa mazao unazidi 1.1 m. | Kurekebisha urefu wa cutter. |

Jinsi ya kutumia Mchanganyiko wa Mchele wa Mchele?

Wakati wa kuvuna, kwa sababu ya kazi nzito, mvunaji wa mpunga mara nyingi hukutana na aina za mazao, mashamba yenye ukubwa tofauti, na hali ngumu na tofauti za asili. Ili kuongeza ufanisi wa kufanya kazi, mendeshaji anapaswa kujua sio tu utendaji wa muundo wa mashine ya pamoja ya mchele lakini pia kwa usahihi mbinu na taratibu za uendeshaji.

- Maandalizi kabla ya matumizi.

Kulingana na matengenezo, lazima kubeba baadhi ya zana muhimu na sehemu hatarishi. Wakati huo huo, ongeza mafuta ya kutosha na mafuta ya kulainisha.

- Maandalizi na njia za kuvuna.

- Unapaswa kujua hali ya barabara, kina cha udongo, urefu wa mazao, na unyevunyevu ili kufanya marekebisho yanayofaa kwenye mashine ya kuvuna ngano.

- Kivunaji kidogo kilichounganishwa kinapoenda shambani, kinapaswa kuingia kutoka kona ya kushoto. Ili kuepuka hasara, nafasi ya wazi ya 1.2m x 2.4m inapaswa kukatwa kwa mkono katika kona ya kulia. Ikiwa shamba sio juu, mvunaji wa mpunga anaweza kufanya kazi moja kwa moja.

- Ikiwa ardhi ni safi kiasi na si ya juu, ili kuboresha ufanisi wa uzalishaji, mashamba mengi yanaweza kuunganishwa kwa mavuno.

Kesi iliyofanikiwa ya mashine ya kuvuna mpunga

Mwanzoni mwa Juni, tulisafirisha seti mbili za mashine ndogo za wavunaji pamoja kwa uvunaji wa mchele kwenda Kongo. Mteja alifika kwenye kiwanda chetu kujaribu mashine na alionyesha kuridhika sana na utendaji wao.

Ili kukuza ushirikiano mkubwa wa muda mrefu, tulimpa sehemu muhimu za vipuri bila malipo, kwani hii ndio ushirikiano wetu wa kwanza. Timu yetu ilichukua uangalifu zaidi katika kupakia mashine kuzuia uharibifu wowote wakati wa kujifungua. Chini ni picha zingine zinazoonyesha jinsi tulivyobeba wavunaji mdogo wa pamoja.

Maswali Yanayoulizwa Mara kwa Mara

Je, mashine mbili za kuvunia mpunga zina upana gani?

120cm kwa aina mbili za mashine.

Urefu wa kukata ni nini?

12-75 cm.

Kuna tofauti gani kati ya mashine zote mbili?

Aina ya kwanza ni umeme unaoanza, na aina ya pili ni aina ya safari (watu wanaweza kukaa).

Je, ni kiwango gani cha upotevu wa mashine zote mbili?

Aina ya kwanza: kiwango cha kupoteza mchele 2%.

Kiwango cha kupoteza ngano cha 3.5%.

Aina ya pili: chini ya 5%.

Je, ninaweza kupata punje safi za mchele au ngano kwa kutumia mashine hii ya kukoboa mpunga?

Ndiyo, mashine inaweza kukata mchele au ngano na kuwapura kwa wakati mmoja.

Je, malighafi ya mashine hii ni nini?

Mchele na ngano tu.

Je, wewe ni mtengenezaji?

Ndiyo, tuko. Karibu kutembelea kiwanda chetu.

Je, unaweza kubadilisha voltage ya mashine kama ombi letu?

Ndio tunaweza.

Vipi kuhusu huduma yako ya baada ya mauzo?

Mhandisi wetu anaweza kwenda nje kusakinisha na kuwafunza wafanyakazi wako kuendesha laini kamili ya mashine.

Wakati wa udhamini wa mashine yako ndogo ya kuvunia iliyojumuishwa?

1 mwaka.