Combined Wheat Rice Harvester Crop Harvesting Machine

Combined Wheat Rice Harvester Crop Harvesting Machine

Rice wheat reaper | Wheat harvester and thresher

Features at a Glance

In the traditional method of harvesting rice, the separate tasks of manual harvesting and threshing not only require a significant amount of labor but also lead to a grain loss of about 10% to 15%.

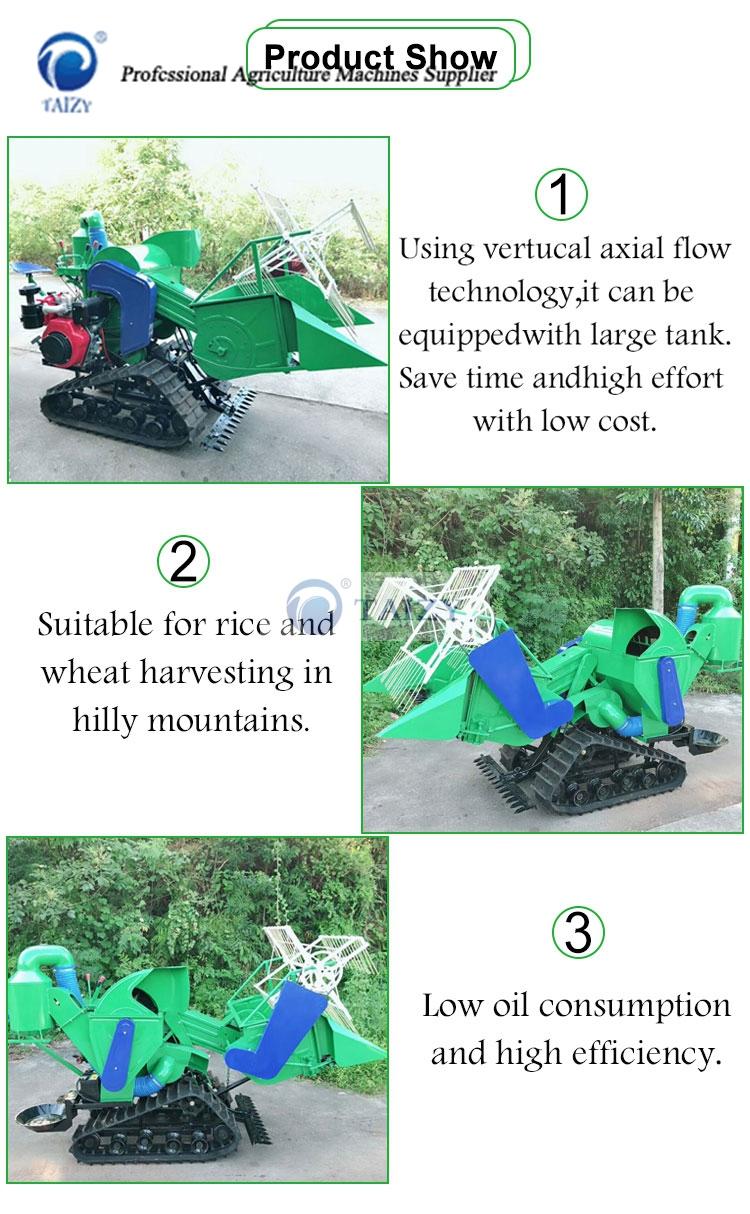

Enter the rice-wheat small combined harvester machine, which cleverly combines the harvesting and threshing processes into one efficient operation. With the ability to cover 50 to 80 mu in a single day and a loss rate of just 1.5% or less, it offers a comprehensive solution for modern farming, taking you seamlessly from the field to the grain silo.

The best part is, you won’t have to invest in two separate machines—a small combined harvester and a thresher. This kind of machine can really help you save both money and energy. In this article, we’ll explore the two different types of rice harvesting machines.

Type one

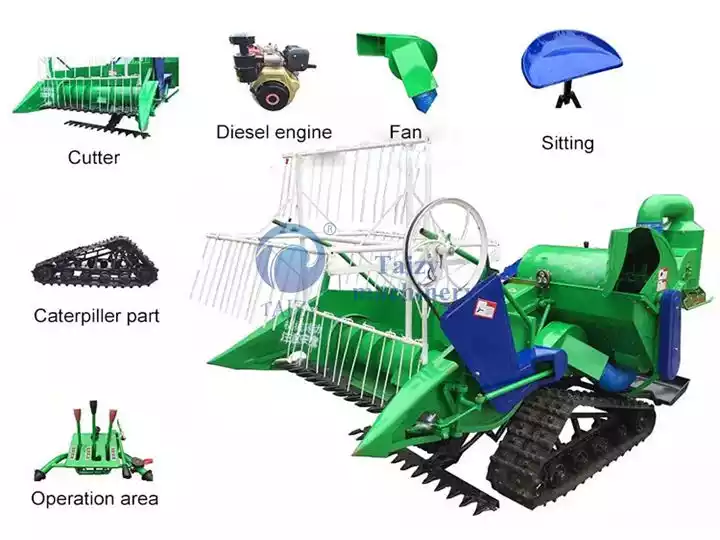

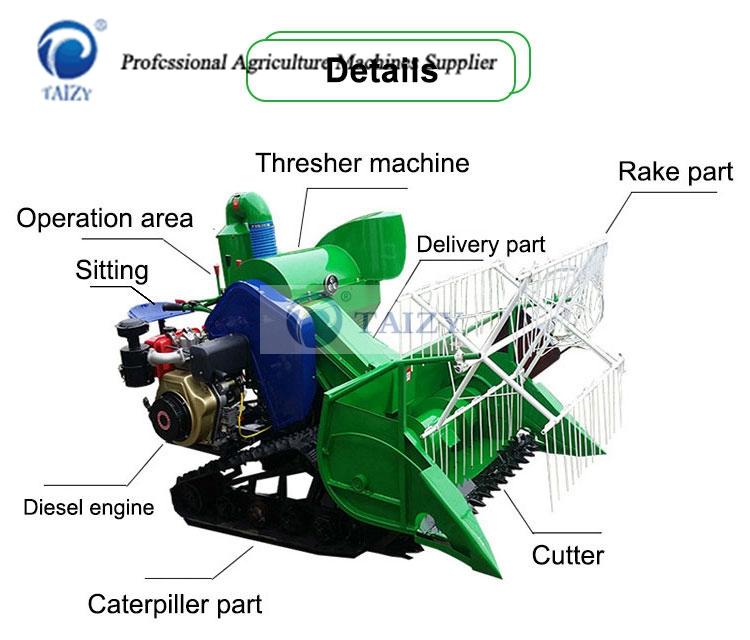

This small combined harvester machine is designed for rice and wheat. It efficiently harvests crops by cutting them directly from the field, while also handling threshing, separating straws, and getting rid of impurities all in one go.

In simpler terms, this machine not only cuts the rice or wheat but also threshes them, giving you clean kernels in the end. Plus, it boasts a low kernel breakage rate of just 1.5% and a rice loss rate of 2%.

Technical parameter of small combined harvester

| Model | 4LZ-0.8(Track) |

| Connection/Drive | Single,shaft,Traction |

| Starting mode | Electric starting |

| Lighting | 12V/100W |

| Cooling | Air cooling |

| Weight | 450 kg |

| Dimensions | 2700*1420*1350 mm |

| Engine Model | 188 F |

| Diesel engine | Single cylinder,horizontal,evaporative water,direct injection |

| Rated power | 13.5 Hp |

| Rated engine speed | 3600 r/min |

| Fuel consumption | 20 kg/hm2 |

| Theoretical working speed | 2.56 (second gear) |

| Productivity | 400-1000m2/h |

| Breakage rate | 1.5% |

| Rice loss rate | 2% |

| Wheat loss rate | 3.5% |

| Rated cutting width | 1200 mm |

| Min ground clearance | 180 mm |

| Caterpillar | Length 800 *Width 250 mm |

| Tire size | 5.00-12 |

Preoccupation of small combined harvester

- The rice harvester machine should go in the field straightly, which can improve working efficiency and avoid crop wasting.

- The user should control the speed of the wheat harvesting machine according to the height, wetness of the crop, and the moisture of the field. Speed down for high crops and speed up for dry fields.

Advantages of rice harvester

- High threshing technology to ensure clean kernels and thorough separation.

- Adopt to three-in-one drum with, a low load, and low breakage rate.

- Wider feeding port: raw material can be put into the machine smoothly without any blockage.

- Wider lift conveyor: makes it easy to convey crops.

- Our combined rice harvesting machine has a reasonable design, high reliability, easy maintenance, and low cost.

- High threshing rate. The threshing rate is more than 95%.

- People can sit on the machine to operate, saving time and energy.

Type two

The small self-propelled combined harvester is designed to handle walking, harvesting, cleaning, and threshing all in one machine, powered by a diesel engine. It allows operators to sit comfortably while working, making it very convenient for farmers.

This harvester offers excellent maneuverability, easy movement, and impressive production efficiency. After harvesting, the crops are fed into the drum for threshing, which helps save time and labor. Its high capacity and low loss rate are among its greatest benefits.

| model | TZY-100A |

| type | Ride type (people can sit) |

| motor | 9.2kw |

| engine | 12.5Hp diesel engine |

| cutting-width | 120cm |

| cutting-height | 12-75cm |

| breakage rate | <5% |

| trash content | <7% |

| capacity | 1000m³/h |

| size | 2600*1340*1540mm |

| weight | 450kg |

Preoccupation of rice harvester thresher machine

- Be sure to read the product manual carefully before use. The structure of the wheat harvester is complicated, although the quality of the machine is very good, you still need to know the inner structure and follow the introduction to operate. Otherwise, the small combined harvester machine will be prone to failure.

- The conditions of harvested crops vary widely such as crop variety, maturity, moisture content, yield, and crop height. Thus, the relevant mechanisms of the machine should be adjusted in time to ensure good performance.

- The protective device installed on the rice harvester is to protect the safety of the operator. Therefore, it cannot be disassembled when working. If it has been disassembled during maintenance, the user should install it again to avoid an accident.

- The combine harvester should be inspected and maintained frequently such as checking whether lacking lubricating oil or water, looseness of the screw and abnormal sounds, etc.

- All the parts of the wheat harvesting machine are designed to be coordinated and cannot be modified at will.

Advantages of rice small combined harvester

- Low breakage late. It is only 5% and you can get very intact and clean kernels.

- High capacity. This combined harvester has a higher capacity(1000m³/h) compared with other harvesters.

- The cutting height is adjustable(12-75cm).

- Easy operation. Only one person can finish all the processes.

- Multiple functions. It can harvest the rice and wheat first and then thresh them to get kernels, which saves time and energy.

| Malfunction | Reason | Solution |

| Cutter is blocked. | 1. Grass and mud on the cutter. | 1. Stop and clear obstacles. |

| 2. The blade gap is too large. | 2. Adjust the blade clearance. | |

| 3. The amount of crop is excessive. | 3. reduce the harvesting width. | |

| 4. Damage to the blade. | 4. Repair or replace. | |

| Reduce the amount of feeding crops, and work with the medium and large throttle. | 1. The crop is shorter than 55 cm. | 1. Try to reduce the stubble height. |

| 2. The cutter transporting rack is damaged. | 2. Repair or replace. | |

| The threshing roller is blocked. | 1. The feeding amount is excessive or uneven. | 1. Control the cutter to cut crops evenly during operation. |

| 2. The drum speed is low. | 2. Working with medium and large throttle | |

| 3. The stem is too wet, and the crop is too high. | 3. Choose dry crops to harvest and increase the stubble height. | |

| 4. The guide plate is detached or worn. | 4. Repair or replace. | |

| The kernel outlet is blocked. | 1. The kernel outlet is full, and the kernel container is not changed in time. | 1. Change the container in time. |

| 2. The stem is wet, and the grain contains weeds. | Adjust the height of the cutter. | |

| The crop head falls down the field. | Harvesting crop height exceeds 1.1 m. | Adjust the height of cutter. |

How to use a combine wheat rice harvester?

During the harvesting season, due to heavy tasks, rice harvester often encounters varieties of crops, fields with different sizes, and complex and varied natural conditions. To maximize the working efficiency, the operator not only should know the structural performance of the combined rice machine but also correctly master the method and operating procedures.

- Preparation before use.

Based on maintenance, you must carry some necessary tools and vulnerable parts. At the same time, you shall add enough fuel and lubrication oil.

- Preparation and harvesting methods.

- You should know the condition of roads, soil depth, the height of the crop, and humidity to make appropriate adjustments to the wheat harvesting machine.

- When the small combined harvester goes to the field, it should generally enter from the left corner. To avoid losses, the 1.2m x 2.4m open space should be cut manually in the right corner. If the field is not high, the rice harvester can work directly.

- If the terrain is relatively neat and is not high, to improve production efficiency, multiple fields can be connected to harvest.

A successful case of rice harvesting machine

At the start of June, we shipped two sets of small combined harvester machines for rice harvesting to Congo. The customer came to our factory to test the machines and expressed great satisfaction with their performance.

To foster a strong long-term partnership, we provided him with some essential spare parts at no cost, as this is our first collaboration. Our team took extra care in packing the machines to prevent any damage during delivery. Below are some pictures showing how we packed the small combined harvester.

FAQ

What is the cutting width of the two rice harvester machines?

120cm for two types of machine.

What is the cutting height?

12-75cm.

What is the difference between both machines?

Type one is electric starting, and type two is ride type (people can sit).

What is the loss rate of both machines?

Type one: rice loss rate 2%.

Wheat loss rate of 3.5%.

Type two: less than 5%.

Can I get clean rice or wheat kernels by using this rice harvester machine?

Yes, the machine can cut rice or wheat and thresh them at the same time.

What is the raw material of this machine?

Just rice and wheat.

Are you the manufacturer?

Yes, we are. Welcome to visit our factory.

Can you change the machine voltage as our request?

Yes, we can.

How about your after-sales service?

Our engineer can go outside to install and train your workers to operate the full machine line.

Warranty time of your small combined harvester machine?

1 year.