Combined Wheat Rice Harvester Machine With Thresher Function

Combined Wheat Rice Harvester Machine With Thresher Function

Paddy Harvesting Machine | Wheat Rice Threshing Harvester

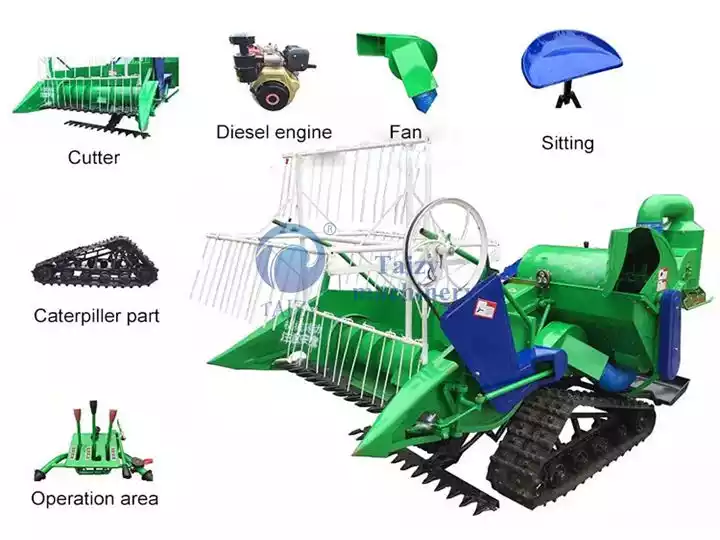

Features at a Glance

The combined wheat rice harvester is a kind of multi-functional combine harvester. It is mainly suitable for small-scale rice and wheat harvesting. It combines reaping, threshing, stripping, winnowing, and packing into a one-time whole-process operation.

This machine can control wheat losses to within 3.5% and rice’s to within only 2%. It is suitable for mountainous regions, hilly terrain, paddy fields, terraced fields, and muddy areas where conventional combine harvesters cannot operate.

This machine alleviates the heavy labor involved in harvesting grain crops for farmers. Its strong adaptability, compact structure, reliable performance, user-friendly operation, and ease of maintenance have made it popular among users and distributors both domestically and internationally.

Two types of combined wheat rice harvester

Taizy company produces two main types of harvesters: triangle crawlers and flat crawlers. Customers can choose according to their farmland soil and other conditions.

The triangle track is suitable for dry land and paddy fields with no deep mud feet, while the flat track has a larger grounding area and is more suitable for paddy fields with deeper mud feet. For exporting to Africa, the triangular track can do the job, while the flat track is recommended for Southeast Asia.

Parameters of wheat harvesting machines

Whether it is a flat crawler or triangle crawler combined wheat rice harvester, both of them are only suitable for different land scenarios. But the individual information parameters are the same, listed below are some of the important technical data of the rice-wheat combine harvester.

| Size(MM) | 3100*1440*1630 |

| Weight(KG) | 570 |

| Cutting width(MM) | 1100 |

| Min ground clearance(MM) | 190 |

| Average ground pressure(KPA) | 10.9 |

| Feeding volume(KG/S) | 1.05 |

| Gear shift | 1,2,3,0,-1,-2,-3 |

| Engine model | KD1100FB DIESEL |

| Rated power(KW) | 11 |

| Power/RPM | 3600 |

| Start method | Electric start |

| Fuel | Diesel |

How does the rice-wheat combine harvester work?

Harvesting

The combined wheat rice harvester machine cuts and harvests crops such as rice or wheat using blades or cutting tables.

Conveying

Employing a conveyor belt or other conveying mechanism, the cut crop is conveyed to the next working unit.

Threshing

The crop is passed through a threshing mechanism, usually a pellet mill or similar device, which separates the seeds(rice, wheat, etc.) from the straw.

Cleaning

The separated seeds are sent to a cleaning system that removes residual impurities, straw, and other unwanted material.

Storage/Unloading

The cleaned seeds can be stored in the machine’s grain storage tank or unloaded into the collector using a conveyor belt, etc. The cleaning system is highly automated.

Wheat rice paddy combine harvester benefits

- Lightweight design allows for easy and nimble steering.

- High threshing technology ensures a clean and thorough separation of seeds and grains.

- Adopting a three-in-one drum, small load, low breakage rate, only 5%.

- Adjustable cutting height, generally 12-75cm.

- Wider feeding opening, the raw material can be put into the combined wheat rice harvester smoothly, with no blockage phenomenon.

- Wider lifting conveyor, so it is convenient to convey crops.

- Equipped with specialized wheels for paddy fields, it can handle mud depths of up to 30 cm.

Wheat rice harvesting machine successful cases

Combined wheat rice harvesters are widely popular in many agriculturally developed and grain-producing countries around the world.

Because many countries grow large areas of rice wheat etc., this machine is a hot seller and used to be shipped to India, Vietnam, Thailand, France, Germany, Russia, the United States, Canada, Australia, Kenya, Nigeria, Brazil, Argentina, and so on.

The following is a live demonstration of a paddy field of a Bangladeshi customer(Related article: Bangladesh Customer Successfully Purchased Taizy Wheat And Rice Harvester Thresher Machine).

Precautions for using the harvester

There are some important things to keep in mind when using a combined wheat rice harvester to ensure that agricultural harvesting is done safely and efficiently:

- Inspection and maintenance: before use, carefully inspect all parts of the machine to ensure that all drive systems, knives, and safety devices are in good condition. Perform regular maintenance to keep the machine in good operating condition.

- Working environment inspection: before starting work, inspect the work area, remove possible obstacles, and ensure a flat, stable surface to minimize bumps and tilting of the machine.

- Adaptation and adjustment: adjust the machine’s tool height, operating speed, and other parameters according to different crop types and growth stages to ensure optimal harvesting results.

- Cleaning up at the end: at the end of the work, clean the machine adequately to avoid residual crop stalks and debris from affecting the next operation.

If you have questions about the harvesting performance of this combined wheat rice harvester machine, you can contact us directly via the form on the right for more videos or detailed machine prices and technical parameters!