Automatic wheat seed planting machine 6 rows wheat planter

Automatic wheat seed planting machine 6 rows wheat planter

Wheat seeder / Wheat seeds sowing machine

Features at a Glance

The wheat planter is a type of seed drill that is specialized for sowing wheat. It can sow seeds and fertilize at the same time. It should cooperate with the tractor to complete the wheat sowing work automatically.

And because farmers plant wheat mostly in plains and hills, and the planting area is large. So if people plant wheat, the efficiency is low and the labor intensity is high. Also, the effect of planting may not meet people’s expectations.

The wheat planter is highly efficient and economical, with good seeding quality and high efficiency, which saves people a lot of time and manpower. After completing your rice planting, you can choose our rice and wheat thresher for harvesting.

Brief introduction of the wheat planter

Wheat planter is a kind of mechanical equipment that plants wheat seeds in the ground through a planting mechanical system. And, it has the characteristics of good general performance, wide application range, and uniform seeding.

The wheat planter is suitable for direct operation after rotary tillage, without soil preparation, saving time and effort. A single operation can complete operations such as leveling, combining moisture, sowing, covering, suppressing, and erecting vertical borders.

Tractors driving the wheat planters for planting. According to customer needs, there are mainly 12 rows, 14 rows, 16 rows, and 20 rows. We also have other models to meet different planting needs. Different functions can match with the wheat planter, such as rotary tillage and fertilization to meet your different requirements.

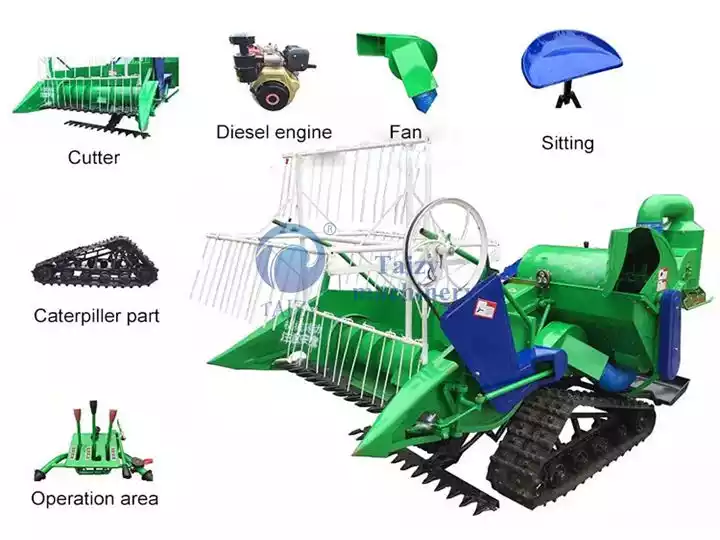

Structure of the wheat seed planter

The wheat planter has parts of a frame, a seedbox, a fertilizer box, a disc opener, a pressing rotating drum, a soil covering board, and the like.

Also, the frame adopts high-quality square tubes, and all functional parts are installed on it. Through the upper and lower suspension arms of the frame, the machine can match with the tractor. Rely on tractor lift control to complete planting and transfer plots.

- The frame is mostly single beam type. Installing all working parts on it and supporting the whole machine.

- Seeding components. The seedbox is connected to a mechanical or pneumatic seed metering device that can achieve precise seeding. It is also connected with an adjustable seed scraper and a seed pusher.

- Fertilizer discharging parts, including discharging box, discharging device, fertilizer pipe, and fertilizing opener.

- Soil working parts. It includes a ditch opener, soil cover, profiling wheel, pressing wheel, seed pressing wheel, and its linkage mechanism, etc.

Workflow of the wheat planting machine

The tractor pulls the seeding device and fertilizing device of the wheat planter to fertilize and sow the land.

First, the tractor drives the colter to open the soil. And the fertilizer pipe enters the opener to start fertilizing the already-opened trench. Then the seeding device is activated to sow into the ground. Finally, the compaction wheel loosens the soil in the trench and compacts it to complete the wheat planting operation.

Working video of the automatic wheat planter

Parameter of the machine

| Model | 2BXF-9 | 2BXF-12 | 2BXF-14 | 2BXF-16 | 2BXF-20 |

| Seeding rows | 9 | 12 | 14 | 16 | 20 |

| Ovwerall dimensions(mm) | 1630*1750*1100 | 1630*2250*1100 | 1630*2450*1100 | 1630*2750*1300 | 1955*3486*1550 |

| Weight(kg) | 298 | 360 | 450 | 520 | 1200 |

| Powder required | 18-30hp; 13.2-22kw | 35-70hp 25.7-36.7kw | 45-85hp 33-62.5kw | 65-110hp 47.7-80.8kw | 95-150hp 70-11okw |

| Rows spacing (mm) | 160 | 150 | 160 | 150 | 150 |

Advantages of the wheat planter equipment

- Ensure that the seeds are most reasonably in the field and that the sowing amount is accurate.

- The sowing depth is the same, creating the best conditions for the growth and development of the seeds. So it can save a lot of seeds, reduce the labor of field seedlings, and ensure a stable and high yield of crops.

- The row spacing is stable, covering the seeds very well, saving seeds, and the work efficiency is high.

- Smooth operation and high seeding quality.

Features of the multi-row wheat planter

- The two sets of grooved discs are a set of connecting bodies, and each disc can work individually.

- The upper end of each ditching disc is equipped with adjustment handles, which are convenient and quick.

- The ditching disc is equipped with a depth-limiting wheel to ensure consistent depth.

- There is a set of adjusting handles for the earth-crushing wheel and the earth-covering board, which is convenient and quick. Each set of covering slabs is provided with a set of springs. The width is equal to the seedling width and the spacing is small, and the effect of covering soil and suppressing is good.

- The extended beam is easy to install and use.

Maintenance of 6 rows wheat planter

The use of wheat planters has a strong seasonality. The maintenance of the equipment is to make it a good working condition, reduce failures, and improve work efficiency.

- When the machine is driving at high speed on the road, the tractor lifter must be locked. It is strictly forbidden to drive by pulling the machine.

- Check all fasteners and connectors before planting. If there is any looseness, tighten it in time.

- During operation, the operator must strictly follow the safe operating procedures to reduce unnecessary wear and tear on the machine.

- After each shift, the soil on all parts of the machine should be removed.

- Frequently check the movement of each rotating pair. If the wear is serious, the corresponding parts should be replaced in time. And paint-stripped parts should be repainted.

- After use every season, it should be cleaned and maintained in time. Be sure to rinse the fertilizer, check all parts, and add rust-preventing oil. And then put it in the inventory.