25 And 30TPD Automatic Paddy Milling Line Rice Processing Plant

25 And 30TPD Automatic Paddy Milling Line Rice Processing Plant

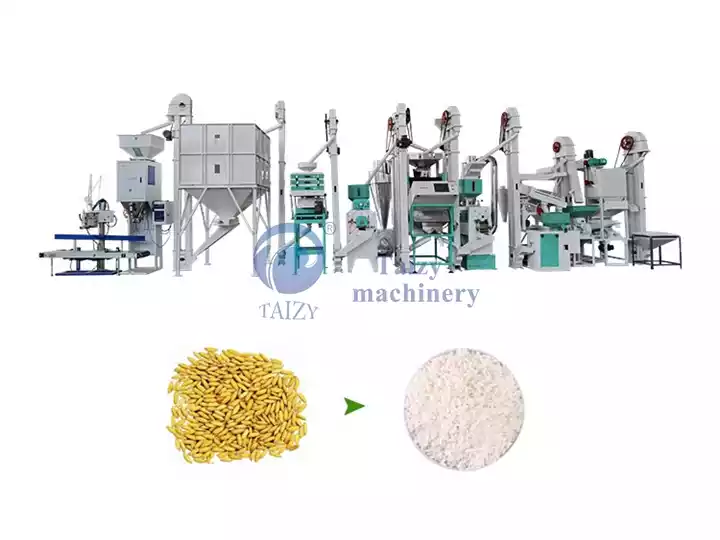

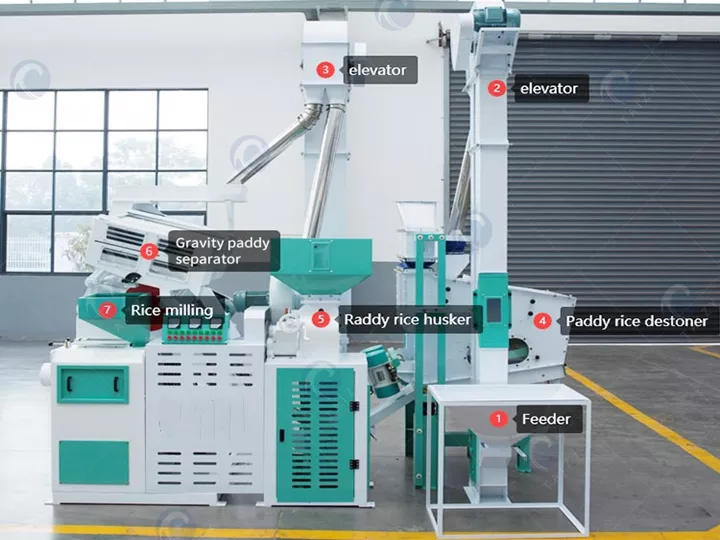

Taizy 25 and 30 Ton/Day capacity rice paddy milling line is a highly efficient, fully automated set of equipment designed for large-scale rice production. The line integrates multiple processes such as cleaning, hulling, milling, and sieving, and is capable of quickly processing paddy into high-quality rice.

Its high throughput and advanced technology ensure production efficiency and milling quality while fully complying with hygiene and food safety standards. This paddy milling line is suitable for use in large paddy fields or rice processing plants, it provides users with a reliable and sustainable rice production solution.

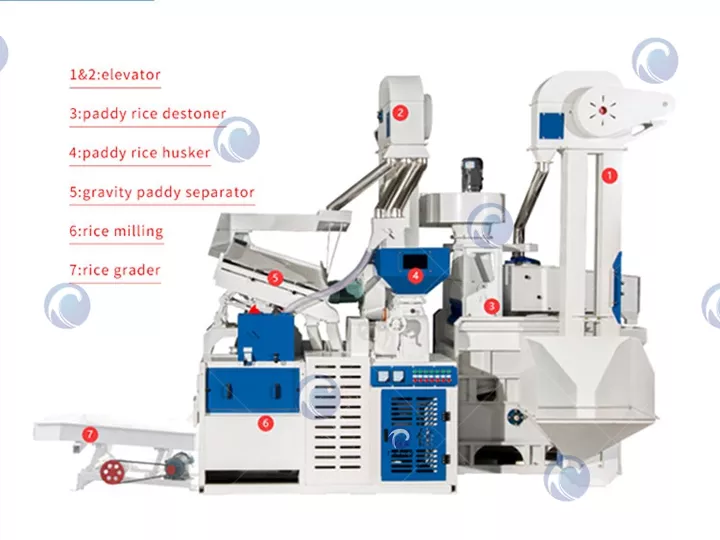

Milltec Rice Milling Solutions Structure And Parameters

The machine’s composition of the 25 and 30-ton paddy milling lines is the same as that of the 15TPD Rice Mill Plant. However, their size increases as production increases. The 25TPD destoner is larger than the 20TPD standard production line and is equipped with a flat gyratory screen.

Both 25 and 30 TPD paddy milling lines have the same composition as well as their functions, only the model and the required power differ. It should be noted that the de-stoner is equipped with two hoists at the back, which function as follows:

- Channel 1: Convey the clean paddy rice to Paddy Rice Husker

- Channel 2: Recycle brown rice and paddy rice mixture back to Gravity Paddy Separator

25TPD Rice Mill Polishing Machines

| No. | Item | Model | Power(kw) |

| 1 | Elevator | TDTG18/08 | 0.75 |

| 2 | Paddy Rice Destoner | ZQS60 | 1.1+2.2 |

| 3 | Elevator | TDTG18/08*2 | 0.75 |

| 4 | Paddy Rice Husker(8 Inch Rubber Roller) | LG20 | 5.5+1.1 |

| 5 | Gravity Paddy Separator | MGCZ80*5 | 0.75 |

| 6 | Rice Mill(Emery Roller) | NS150 | 18.5 |

| 7 | Rice Grader | 40 | 0.55 |

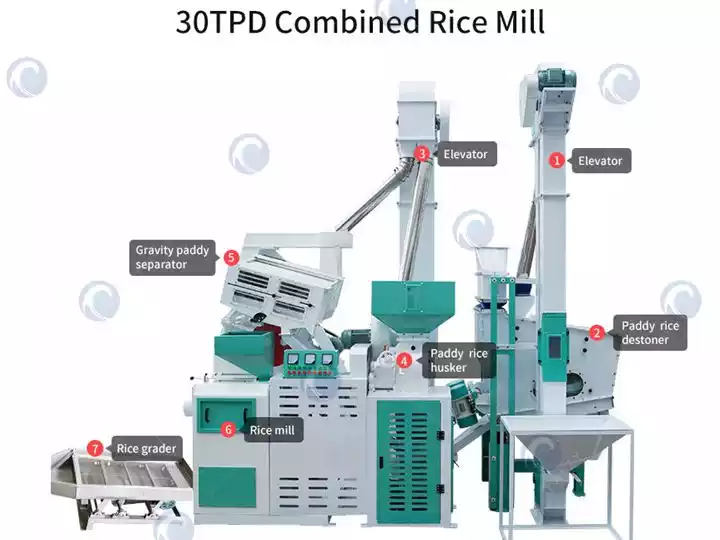

30TPD Paddy Milling Processing Line

| No. | Item | Model | Power(kw) |

| 1 | Elevator | TDTG20/11 | 1.1 |

| 2 | Paddy Rice Destoner | ZQS70 | 0.5+3 |

| 3 | Elevator | TDTG18/08*2 | 1.1 |

| 4 | Paddy Rice Husker(8 Inch Rubber Roller) | LG20 | 5.5+1.1 |

| 5 | Gravity Paddy Separator | MGCZ80*7 | 1.1 |

| 6 | Rice Mill(Emery Roller ) | MNMS15B | 18.5 |

| 7 | Rice Grader | 40 | 0.55 |

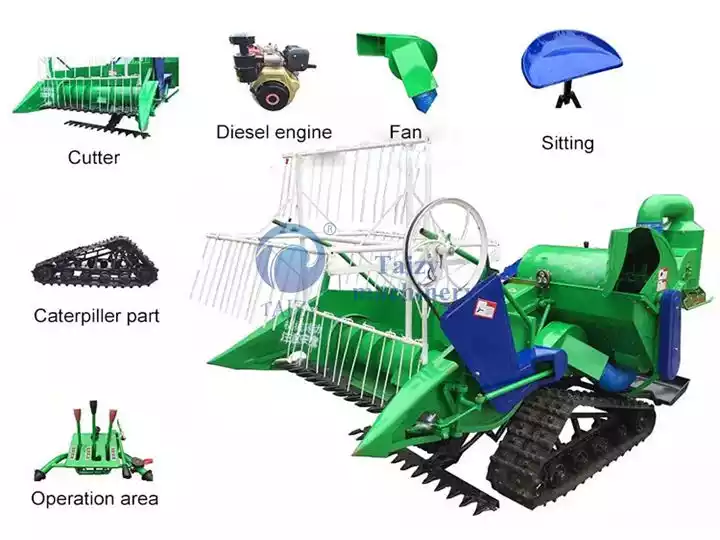

Paddy Milling Line Main Application

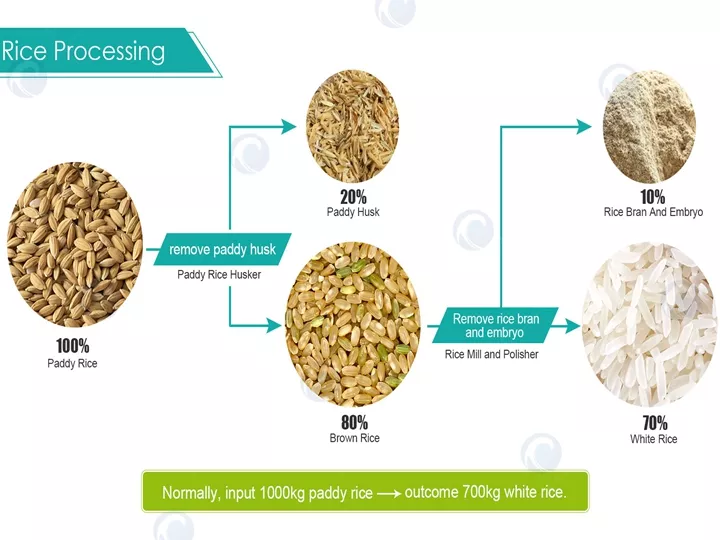

This rice milling unit of ours can take paddy harvested from the field (raw grain humidity needs to be kept below 12.5%) and produce white, clean rice through a series of operations as shown in the picture below. The final rice obtained is 70% of the original grain, rice bran and embryo is 10%. Normally, input 1000kg paddy rice → outcome 700kg white rice.

Benefits And Functions Of Automatic Rice Mill Plant

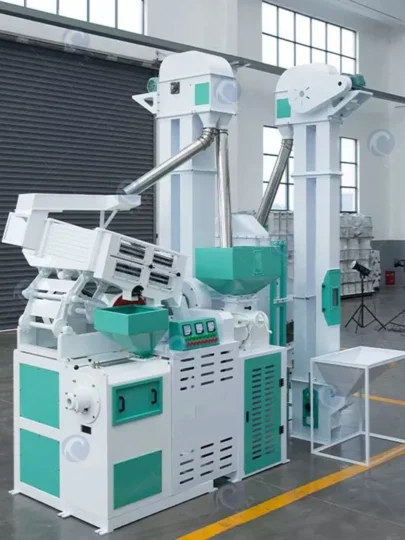

- This paddy milling line adopts the way of arrangement and combination, and the appearance is more beautiful and compact;

- Anchor screws are added to the eccentric running part to enhance the stability;

- The height of some parts of the machine is reduced, which makes it easy to operate (especially suitable for individual farmers’ processing);

- The combination and separation of each part can be done independently, making maintenance and transport more convenient.

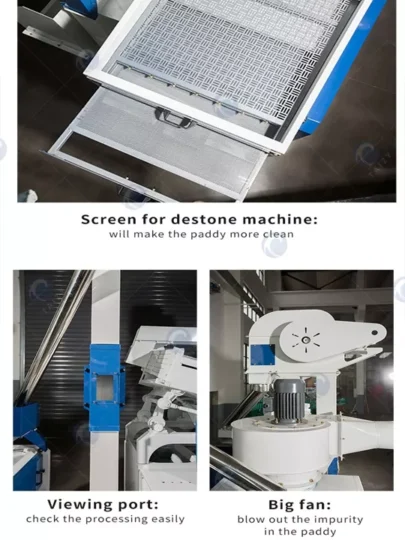

- Adopting suction-type stone remover, the effect is more reliable and stable, and it can also reduce dust pollution in the feeding process;

- Strong practicality, this paddy milling line not only processes individual agricultural products but also continuously processes commercial grain;

- Increased crushing process, convenient for farmers to mix large chaff and net chaff, one-time processing into chaff powder so that by-products are fully utilized.

White Rice Making Machines Details

Here are some of the important components that make the machine work. Of course, if you would like to see more pictures as well as videos, etc., feel free to contact us to get them.

Rice And Paddy Processing Machines Successful Cases

The versatility and applicability of paddy milling lines to meet the needs of different markets on a global scale are usually more popular in the main rice-producing regions of Asia, Africa, and Latin America. Our large-scale rice milling machines have been shipped to many countries, including Kenya, Nigeria, Malawi, Ghana, Pakistan, and so on.

In addition to several standard lines, we also have more advanced upgraded extensions, which you can choose on demand according to the budget cost and the degree of requirements for the finished product, etc. Please browse our website and feel free to contact us!