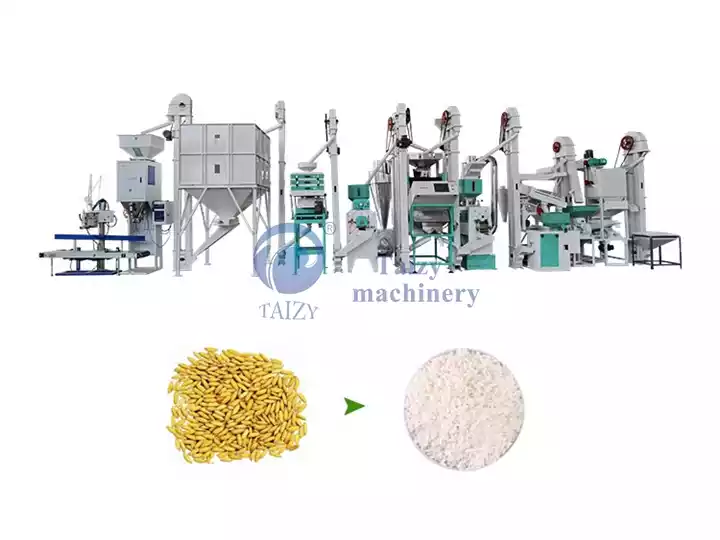

High Standard 15TPD Rice Mill Line With Water Polisher And Storage Bin

High Standard 15TPD Rice Mill Line With Water Polisher And Storage Bin

Welcome to our upgraded rice mill line’s advanced production plant, which combines color sorting and packaging machines with a high-standard water polishing machine and intelligent storage bin to provide you with the ultimate rice processing experience.

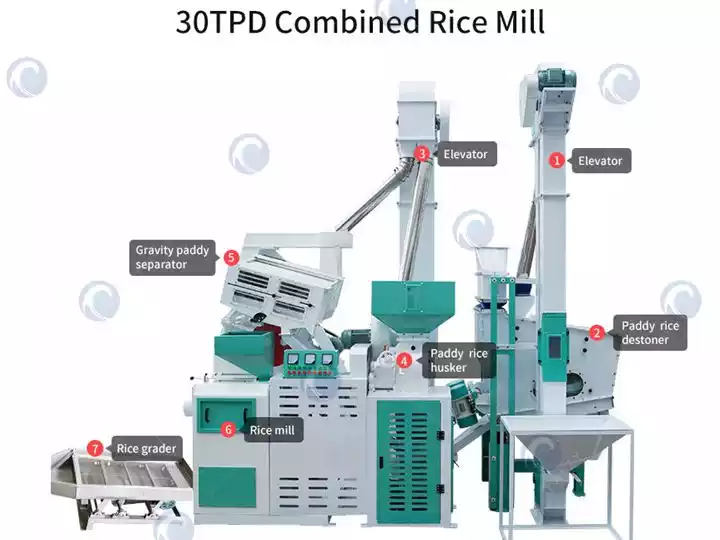

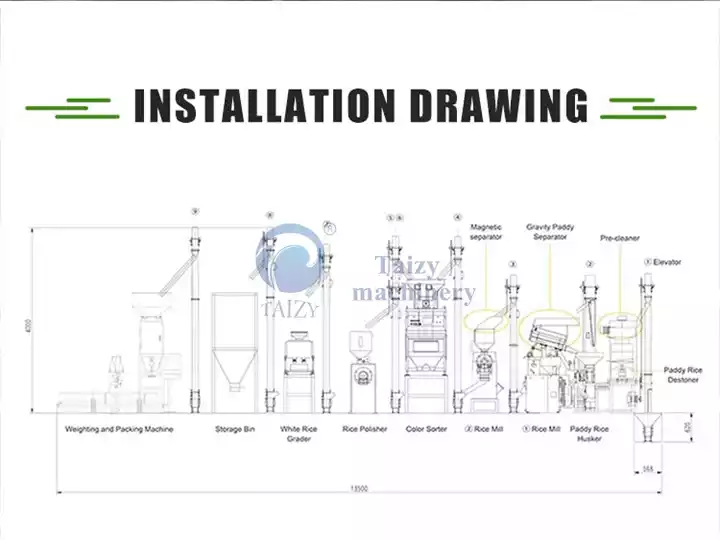

High Standard 15TPD Rice Mill Line Structure

1. Necessary Parts : (you need to buy all )

Pre-cleaner— Destoner— Paddy Husker– Gravity Separator —-Rice Mill—

2. Optional Parts : ( you can choose one or more from the following machines according to your money )

Rice Polisher—Rice Grader—-Color Sorter—Storage Bin —Weighting and Packing Scale

Outcome: The more machine you buy, the white and smoother the rice quality will be.

Solution For 600-800kg/h Rice Mill Line Equipment

| Specification | Function |

| Paddy Rice Husker Model: LG15Power:5.5kw | Separate the brown rice from the paddy by the difference of gravity and surface friction |

| Paddy rice Pre-cleaner Model: SCQY40 Power:0.75+3 | Mainly to remove the stone in the paddy, but also remove some bigger straw than paddy rice and smaller sand or dust than paddy rice. |

| Paddy Rice Husker Model: LG15 Power:5.5kw | Remove the outside husk to get brown rice |

| Gravity Paddy Separator Model:MGCZ70*5 Power :0.75kw | Use the 2nd rice mill to get whiter rice and decrease the breakage rate. |

| First Rice Mill Model:NS150 Power:15kw | Use the 1st rice mill to remove the brown skin to get white rice |

| Magnetic Separator | Remove small metals from rice |

| Rice Polisher with water Model: MP12.5 Power:15kw+4kw | Selecting out other colors of rice or mildew rice from white rice. |

| Rice Polisher with water Model: MP12.5 Power:15kw+4kw | Polish the white rice with spraying water, making it whiter and lighter. |

| Color Sorter Model:6SXM-64(CCD) Power :1.5kw | Get whole rice into 2 grades and Separate whole rice and broken rice. |

| White Rice Grader Model:MMJP50X2 Power:0.35kw | The finished rice can stay in the bin long time, with no need for one person to work by the packing machine non-stopping If you want to save labor, we can set up one storage bin before the packing machine. |

| Storage Bin and elevator Volume:3tons | To remove dust, rice husk, and other small impurities |

| Weighting and Packing Machine Model: DCS-50 Power:0.37+0.37kw | Weighting, Filling into the bag, and sewing the bag.Weighting scope: 5-50kg |

| White Rice Grader Model: MMJP50X2 Power:0.35kw | Used to connect all machines working together |

| Dust collecting pipes and Cyclone and other small accessories | To remove dust, rice husk, and other small impurities |

| Electric Cabin | Easy and safe for operation |

| Tools | Tools for installation and maintenance |

Why Use A Water Polisher Machine

- The water polisher and rice milling machine look very similar, the main difference is that the water mist polishing machine is equipped with a water hose, a water pump, and a water bucket.

- The rice mill machine can use iron rollers or emery rollers, while the water polisher uses iron rollers. The function is mainly with a fine water mist to make the rice become smoother and whiter.

What’s The Function Of Storage Bin

- Because the packing machine is very fast, it can pack a 50kg bag of rice in less than a minute and therefore can pack three tons of rice per hour. A 15TPD rice mill line produces 600kg of white rice per hour.

- If a 3-ton storage bin is placed in front of the packaging machine, it takes 5 hours to fill the bin. When the bin is full, the packer is turned on and the packing process begins. In this way, the packing machine does not have to work constantly and an operator does not have to be there all the time.

Referable Design Drawings

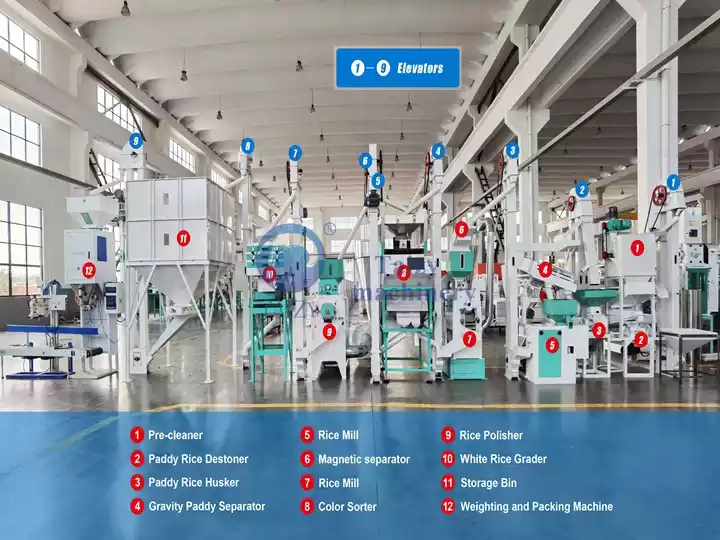

Taizy Rice Mill Line Machines Factory Show

Welcome to the advanced production line of our upgraded rice mill line, which combines color sorting and packaging machines with a high-quality rice polisher with water and an intelligent bin, presenting you with the ultimate rice processing experience and demonstrating our company’s commitment to providing advanced technology and high-quality rice production process, we look forward to your visit and cooperation.