Rice miller machine | Small household rice mill |Rice milling machine

Rice miller machine | Small household rice mill |Rice milling machine

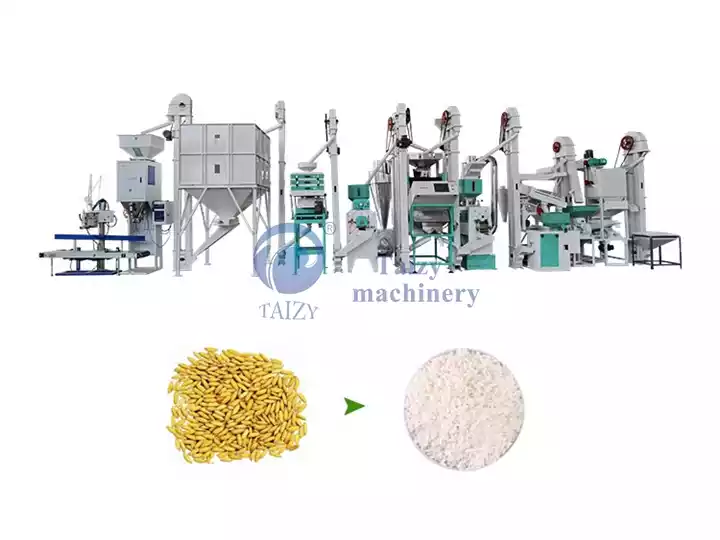

Introduction of rice miller machine

The rice miller machine is a device that uses the force of mechanical equipment to peel and whitens brown rice.

The working principle of the rice miller machine

When the brown rice flows from the hopper into the whitening chamber, due to the internal pressure of the pressing thallium and the mechanical force, the brown rice is squeezed in the whitening chamber. After friction and the friction between the brown rice and the grinding wheel, that is, It can quickly remove the skin layer of brown rice, and reach the level of fine whiteness measured by white rice within a certain time of adjustment.

Structure of rice miller machine

The rice miller machine consists of a hopper, a rice milling chamber, a discharging port, and an adjusting handle, etc.

Advantages of rice milling machine

The rice mill is compact in structure and beautiful in appearance. And the small size is easy to move. And lower energy consumption will have a long service life. Easy to operate and maintain. Besides, various varieties of rice can be processed to separate the rice husk and rice bran. Generally, the rice yield rate of rice reaches more than 95%, and the broken rice rate is low. So that the processed finished rice is bright, white, fragrant, and very delicious. Small household rice mills can also be used for the dehulling of corn, wheat, barley, mung beans, buckwheat, and coffee. Thus it becomes a good machine for individual households, urban supermarkets, grain shops, farmer’s markets, etc. for on-site processing.

Models of rice mill

Now we have three different grades of rice mills, namely the basic model, the upgraded model, and the latest model.

The basic model can meet daily production needs, but the upgraded model has been upgraded in color and function. The broken rice rate is low, so the rice milling efficiency is higher, and the performance is better. what’s more, the latest model adds the stone removal function compared to the upgraded model. Because once hard objects such as stones, iron blocks enter the rice milling room, it will cause irreversible damage to the working parts of the rice milling room, thereby reducing the service life of the rice milling machine. thus, the increase in stone removal parts of the latest rice mill can reduce this kind of damage and prolong its service life. At the same time, it will make the milled rice more translucent and white.

The basic model

The upgraded model

The latest model

Working video of rice mill

Parameters of rice mill

| Model | type 80 Rice Mill |

| Spindle speed | 1600r/min |

| Meter roll diameter | 80mm |

| Productivity | ≥150kg/h |

| Rice output rate | ≥65% |

| Broken rice rate | ≤30% |

| Electricity consumption per ton of material | ≤12KW.h/t |

| Voltage | 220v |

| Rated power | 2.2KW |

| Accessories | In and Out Hopper Motor Wheel V-belt |

| Dimensions (mm) | 670x400x1090 |

| Packing size (mm) | 590x660x340 |

| Weight | 30kg |

Different configurations of rice mill

You can also add a Shakron dust removal device and self-suction feeding device according to your own needs. In addition, if electricity is not convenient, it can also be equipped with gasoline engine power.