Corn Maize Harvester Machine

Corn Maize Harvester Machine

Agricultural harvesting equipment/Corn harvesting machine

Features at a Glance

Corn maize harvester machine is used to harvest corn from fields and divide it into two types including hand-operated corn cutter or tractor-driven corn cutter. They bear different capacities and structures, but the harvesting effect is perfect. After harvesting the corn. We can also use the corn thresher to get corn kernels. And if we want to process the corn further. We can also use the corn grinding machine to process the corn into flour.

Type one

This maize harvester machine developed by our company bears a new design, adopting domestic first-class mechanical drive and hydraulic drive technology. And it is easy to control and operate. Also, the corn maize harvester machine integrates the picking, conveying, peeling, packing, and straw crushing as a whole, meeting the needs of users in different regions.

The corn harvester machine with straw returning should cut as far as possible after the corn is ripened for 3 to 5 days. In this way, the kernel of corn is full and the water content is low which is good for peeling the corn husk. In addition, yellow straws with low water content can be effectively crushed, reducing labor time.

Technical parameter of corn cutter

| Model | CH-2 | CH-1 |

| Cylinder | 4 | 1 |

| Dimension | 4850*1450*2600mm | 3950*910*1460mm |

| Weight | 2680 | 700 |

| Row | 2 | 1 |

| Cutting width | 1135mm | 650mm |

| Row spacing | 420-890mm | / |

| Max cutting height | 2120mm | / |

| Minimum distance from ground | 150mm | 200mm |

| Working speed | 2.2-5.0km/h | / |

| Capacity | 0.15-0.3hm2/h | 0.05-0.12hm2/h |

| Fuel consumption | Front-wheel(1200mm) Back wheel(1300mm | / |

| Peeling roller | Spiral rubber roller | Spiral rubber roller |

| Peeling device | 8 peeling roller | 4 peeling roller |

| Shaft distance | 2300mm | / |

| width of straw returning to the field | 930mm | / |

| Wheel distance | Front wheel(1200mm)

Back wheel(1300mm | 760mm |

Advantages of corn harvesting machine

- 8 peeling rollers inside the harvesting corn machine can remove the skin of corn after harvesting, saving labor time.

- And corn harvesting machine has a big size, and it is more stable than other types during operation.

- Also, it integrates picking, conveying, peeling, packing, and straw crushing as a whole.

- The loss rate of corn is pretty low: less than 3%.

- What’s more, there is a cab on the upper of the machine, and people can sit in it and run the corn maize harvester machine easily.

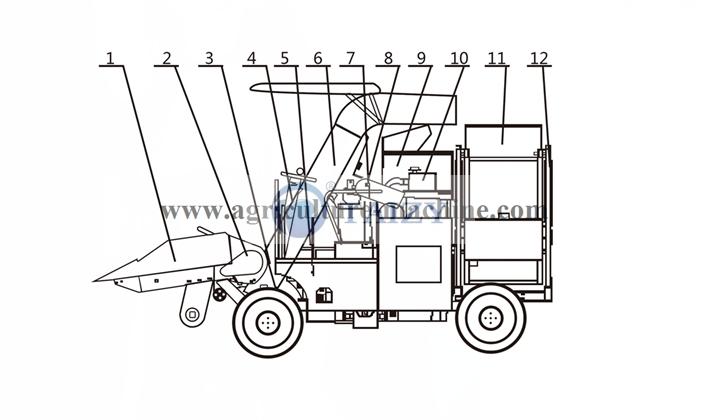

Structure of corn harvester equipment

- Corn cutting part Winch assembly 3. Rack assembly 4. Operating system 5. Covering 6. Lifting parts 7. Electrical system 8. Safety marking 9. Peeling machine 10. Transmission system 11. Grain box assembly 12. Hydraulic system

Maintenance of several important parts of maize harvesting equipment

1. Engine

The temperature of the muffler on the corn cutter is quite high. So, the user must clean the debris around the engine exhaust pipe according to the situation, and keep the engine, especially the exhaust pipe clean.

2. Main clutch

(1) The operator should always check the working status and performance of the main clutch, and it should be repaired or adjusted in time if there are any impurities on it.

(2) Also, regular lubrication should be carried out.

(3) When disassembling and assembling, you shall be sure to properly assemble the separation bearing and separation bearing cover as required.

(4) It is necessary to ensure the correct position of the rear dynamic pressure plate and fixed pressure plate to prevent the adjustment of the clutch clearance due to the collision between the rear movable claw guide sleeve and the fixed plate separation spring guide pin.

(5) We should check the complete condition of the clutch connecting pin, the connecting rod, and the split pin in time. If the gap between the pin and the hole is too wide, we should replace the split pin in time to prevent accidents.

3. Straw chopping device

(1) Tighting the power fixing bolts of the corn maize harvester machine.

(2) The movable blades should be replaced in time after wear due to long-term use, but you shall pay attention to the direction of the blades when replacing.

(3) Check the working condition of the moving shaft driving chain in time, and when the chain is lost or deformed. It is necessary to fill the joint or replace the chain in time, ensuring that the sprocket circuit is correct.

4. Steering bridge assembly

Pay attention to the fixing condition of the steering rod to ensure the fixing is reliable.

5. Hydraulic system

(1) Looking over the sealing of hydraulic pipelines. There shall be no oil leakage between joints and valve joints.

(2) The pressure of the reversing valve has been set before delivery, and it is forbidden for the user to blindly increase the pressure to prevent the pipe valve from being broken after being subjected to high pressure.

(3)The same type of hydraulic oil must be used from beginning to end to prevent the chemical reaction caused by the mixed oil.

(4) Hydraulic oil must pass the oil filter to prevent dirt from entering the system, causing damage to the hydraulic components.

(5) Also, the hydraulic valves of the corn cutter must be carried out by professional maintenance personnel.

(1) Straw blockage

Reason: The position of the picking board is not suitable (the gap is too close), and the transmission triangle belt is too loose.

Solution: Adjust the clearance of the picking plate to the appropriate size. Due to the different thicknesses of the straw, the tension of the transmission belt is adjusted between 20-50mm.

(2) The smashed straw is too long

Reason: The clearance of the movable knife is too long, and the blade of it is not sharp.

Solution: Change the clearance between the fixed knife and the movable knife ranging from 0.3-1.5mm.

(3) The peeling effect is not good

Reason: The peeling rubber roller is seriously worn, slipping from the driven rubber roller.

Solution: We should change the pressure of the stripping roller by adjusting the bolts or replacing the stripping roller.

(4) Common faults in the gearbox

Phenomenon: The gearbox has abnormal noise, oil leakage, or overheating.

Reason: Gear or bearing is worn. The installation direction of the oil seal is wrong or aging. The side gap is too close and there is little lubricant oil.

Solution: 1. Adjust the gear or bearing installation clearance.

- Replace damaged parts.

- Reinstall or replace the oil seal.

- Tighten the bolts and adjust the oil to the appropriate height.

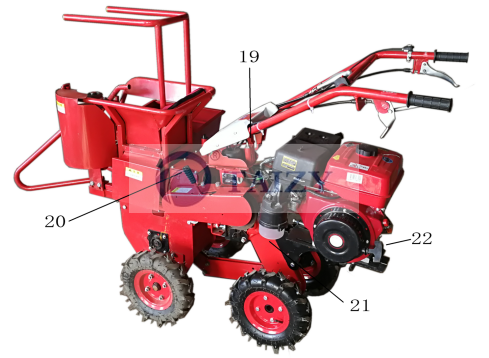

Type two

It is a small size corn harvesting machine and suitable for individual farmers. The corn maize harvester machine is easy to operate in the field, and one person can finish all the processes. What’s more, due to the new design of a small container at the side of the corn maize harvester machine, corn can directly fall after harvesting. In addition, this cutting corn machine also can crush the corn straw into pieces, increasing the nutrition of the soil.

Technical parameter of hot sale maize harvester

| Name | Corn Harvester Machine |

| Model | TZY-10 |

| Engine | Diesel engine |

| Capacity | 500kg/h |

| Size | 1690*830*1020mm |

| Weight | 93kg |

| Type | Hand manual operation |

| Structure | Front-mounted |

| Transmission mode | Triangle belt |

| Connection mode | Direct connection |

| The adjustable angle of handles | 180/ 360 |

| Number of blades | 24/32 |

| Tilling width | 920mm |

| Tilling Depth | More than 100mm |

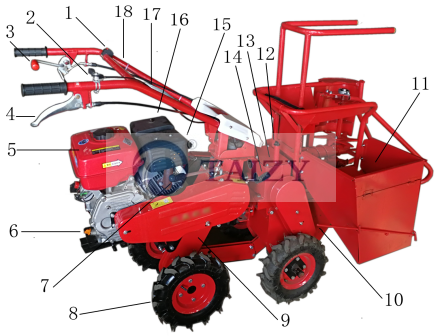

The detailed structure of corn cutter

1. flameout switch 2. Accelerator 3. Walking clutch

4. Armrest height adjustment grip 5. fuel tank 6. engine oil filler

7. forward I, II, reverse gear, shift gear 8. tire 9. travel gearbox

10. opening rod of corn storage tank 11. corn container

12. harvesting gearbox fuel filler 13. harvesting gearbox 14. shift lever of high and low gear 15. muffler 16. air filter 17. armrest grip

18. armrest frame 19. oil filling inlet of the walking gearbox 20. corn harvest clutch

21. filter oil cup 22. Hand-operated handle

Advantage of corn cutter

- Corn harvester price is low and almost all farmers can afford it.

- It just needs one person to push forward, which is easy to operate.

- The angle of the two handles is adjustable.

- It is small in size and light in weight and can apply to many fields such as plants, hills, mountains, etc.

Type three:3 row corn harvester

It is a 3-row corn harvester machine with a capacity of 1-1.5 acre/h. Compared with the first two types, it needs a higher engine, 103kw. The applicable range of row spacing is 650mm, and the cutting width is 1825mm. Corn cutters can run with high working efficiency, which makes sure that the loss rate is less than 4% and the corn breakage rate is less than 1.0%. Honestly, there is a little impurity in the final corns, and the impurity content is less than 1.5%. All in all, it is a good tool for farmers.

| Capacity | 1-1.5acre/h |

| Structure type | Self-propelled wheel |

| Driving mode | 2-wheel drive |

| Power | 103kw |

| Engine speed | 2300 r/min |

| Harvesting lines | 3 rows |

| Applicable range of row spacing | 650mm |

| Cutting width | 1825mm |

| Peeling Roller Material | Iron roller & Rubber roller |

| Minimum ground clearance | 290 mm |

| Unit area fuel consumption | ≤ 20 L/hectare |

| Granary Volume | 1.5m3 |

| Total loss rate | ≤ 4% |

| Grain breakage rate | ≤ 1.0% |

| Content of impurities | ≤ 1.5% |

| Peeling rate | ≥ 85% |

| Size | 6190*2300*3259mm |

| Weight | 4990kg |

| Stubble height | ≤ 50mm |

| Straw comminution rate | ≥ 85% |

Type four:4 rows corn cutter machine

4YZP-3A self-propelled has low noise and flexible operation and it can open the cutting path, and the cutting roll can realize cross-cutting, oblique cutting, and non-line harvesting. With high efficiency, it is equipped with a 140 horsepower engine, so it is energy-saving and environmental protection. The 16-roll peeler has a high peeling rate and high-quality straw crushing. With hydraulic steering, it is hydraulic unloading and waste recovery.

Technical Parameters:

| Model | 4YZP-3A |

| Capacity | 0.5-1.3acre/h |

| Size | 6250*2000*3200mm |

| Weight | 4600kg |

| Harvesting lines | 3 rows |

| Power | 140hp |

| Applicable range of row spacing | 450-650mm |

| Cutting width | 1800mm |

| Amount of Peeling Roller | 16 pcs |

| Granary Volume | 2m3 |

| Width of Returning Machine | 1700mm |

| Cutting center distance | 550mm |

This corn harvester also has a big size and high working efficiency(0.3-0.8hm2/h), and it can harvest 4 rows of corn. It is driven by a 175hp diesel engine, so it can work in the field with high speed, saving much time and energy.

| Model | 4YZ-4F |

| Capacity | 0.3-0.8hm2/h |

| Size | 7200*2450*3500mm |

| Weight | 6350kg |

| Harvesting lines | 4 rows |

| Power | 175hp |

| Applicable range of row spacing | 500-600mm |

| Granary Volume | 2.3m3 |

Successful case of corn maize harvester machine

For type one

We once sold 200 sets of maize harvesters to Nigeria, which is a big project for our customers. Due to the big size, one 20GP just can only contain one corn maize harvester machine. The following pictures are the details they received from the corn maize harvester machine in their country.

For type two

At the beginning of April 2019, the customer we have cooperated many times ordered 32 sets of corn harvester machines. The first cooperation between us was in 2015, with 4 years going on, he still trusted us and placed an order from us again and again. We are preparing the corn maize harvester machine now and are trying our best to produce a corn maize harvester machine with the best quality.

FAQ of corn cutter

Type one

How many rows can be harvested?

One row.

What is the loss rate?

≤3%.

What is the minimum distance from the ground?

200mm.

Type two

Can this harvester peel the skin of corn?

No, it can’t.

Where is the corn straw after harvesting?

They will return to the field after crushing by 10 blades in the bottom of the corn harvester.

What is the stubble height?

It can be adjusted, but the minimum height is 10cm.

How many crushing blades?

There are 10 crushing blades in the bottom.

Are the blades easily broken parts? How long can I use it?

Yes, the blades are easily broken parts, especially when meeting with big stones or other very hard obstacles. Usually, it can be used for one year.

We send you an extra 1 unit (10pcs) for free with the corn harvester when delivery.

What power does this corn harvester use?

188F gasoline engine or 188F air-cooling diesel engine.

Will some corn cannot be harvested?

With the practice experience, the corn harvesting rate is more than 98%.

How much corn can be collected in the container at the side of the corn maize harvester machine?

Depending on the corn size, usually, it can collect 30-50pcs.

Can it harvest sweet corn?

Yes, it can harvest sweet corn.

How many sets can be loaded in 20GP and 40HQ?

20GP can load 26 sets, 40HQ can load 54 sets.

What is the delivery time for 100 sets of corn harvesters?

Usually, it takes one week.

Are the cutting width and height adjustable?

No.

Can the corn skin be removed during the operation?

No, this corn maize harvester machine just harvests the corn.

How many rows can it cut?

Just one row.