Corn, maize grits making and milling machine

Corn, maize grits making and milling machine

Corn Grinding Machine / Maize Grits Milling Machine

Features at a Glance

Corn grits making machine is the equipment that can process corn kernels into corn grits and corn flour. Nowadays, corn grits and corn flour are the most common forms of corn consumed in people’s daily lives. Because ground corn is easy to eat and digest and can be further processed into foodstuff. Therefore, the corn grits machine has become popular in the market.

To meet the needs of different customers, we have produced five different models of maize grit milling machines. They differ in terms of output, appearance, and function. People can use the corn threshing machine to process the corn first and then proceed to further processing.

Introduction of corn grits milling machine

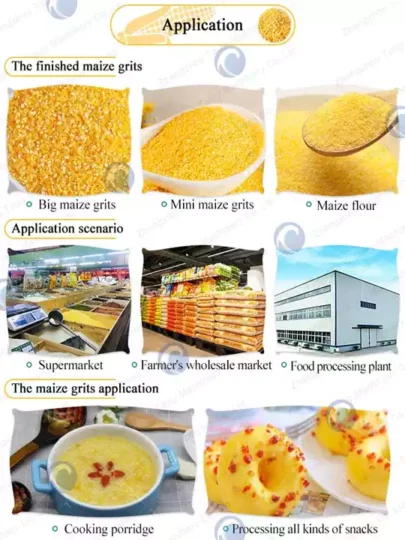

Corn peeling and grits making machines are to peel corn and then process it into three different shapes, namely large corn grits, small corn grits, and corn flour.

Maize grits making machine can complete cleaning, peeling, germ removal, root removal, black navel removal, crushing, grinding, grading, and polishing of corn grits at one time. The machine can complete all the processes to produce different grit sizes and cornflour of different meshes.

Dried corn with less than 12% moisture was first put into the peeling section. Then it goes into the second part for grinding, passing through a flour sieve and a grits sieve to get corn flour and grits of different sizes.

We manufacture five models of corn grits making machines, they are PH, C2, T1, PD2, and T3. These machines are compact in structure, simple in operation, and it is energy-saving, efficient, and durable.

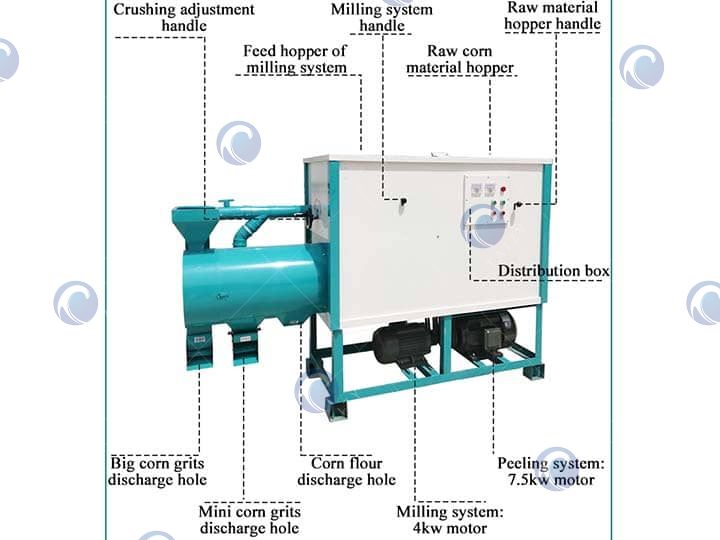

The main structure of the corn grits making machine

Corn grits making machines mainly have a peeling system, grits production system, finished product classification system, dust removal system, frame, and power distribution system.

Peeling system

- The peeling system includes a feeding device, a shell breaking, and whitening device, a bran separation device, and an automatic adjustment system for the discharge.

- The feeding device mainly has a feeding hopper, a hopper seat, and an insert plate. The hopper can store a certain amount of corn and make the corn enter the peeling room by gravity. The inlet gate can control the flow rate of the materials.

- The peeling device mainly includes the discharge hole, the fuselage, the reduction box, the fan, the tensioner, the bean hopper, the bran collector, etc.

Grits making system

The grits-making system is mainly composed of the propeller, clutch, step-less crushing handle, etc.

Finished product grading system

Corn can be divided into three ways for different degrees of processing, corn kernels, corn grits, and corn flour.

Air network dust removal system

It has fans, air ducts, and dust collectors.

Frame

It is composed of international high-quality angle steel and channel steel. And we made it through many processes such as cutting, chamfering, precision welding, etc.

Corn is an indispensable food in many countries. Corn grits and maize flour can not only be used to make soup but also to make staple foods such as Fufu, Ngima, Sima, Gima, Posho, etc. In addition, corn grits can also be processed into puffed food, which is very popular.

Working principle of maize grinding machine

After the corn enters the dehulling room from the hopper, it moves toward the exit under the rotation and push of the propelling ribs. In the peeling room, due to the gradual reduction of the volume of the working room and the influence of the resistance of the maize grit grinding machine, the density between the corn decreases, and the pressure increases accordingly.

So, the squeezing and friction of corn in the corn grinding mill machine are strengthened. With the continuous advancement of the roller, the friction and stripping are continued to gradually remove the corn. The corn kernels and bran skins achieve the effect of automatic separation. And finally, the finished peeled corn flows out through the discharge port. The bran skin is discharged from the other outlet.

Working process of corn grits making machine

- Firstly, put the clean corn kernels into the grinder hopper, and then move forward through the traction clutch crusher.

- They will then be peeled and crushed, removing 30% of the corn husk.

- Then the crushed corn enters the classification system and is separated by three round screens. So the corn with different shapes is respectively discharged from the three outlets finally. In this process, the micro-skins in corn grits are sucked away by the action of wind through the fans to get fine grits. And you can adjust the damper to determine the wind force. The micro skins blown out by the fan can be collected in bags.

Before using this corn grits making machine, you can first clean the corn kernels with our grain cleaning machine, click to learn more: High-Efficiency Maize Corn Cleaner Grain Cleaning Equipment For Sale.

Working video of the corn grinding mill machine

Specifications of the corn grits grinder

| Model | ZX-T1 |

| Corn peeling | 350-450kg |

| Making corn grits | 1000kg |

| Rated voltage | 380v |

| Power | 7.5 kw 4 pole |

| Making corn flour | 350kg |

| Spindle speed | 1150r/min |

What advantages does a corn milling machine have?

- Unique design solves technical difficulties such as the slow removal of impurities.

- Equipped with the current display system. So, you can see the internal pressure of the working room and the peeling effect of corn.

- A newly added automatic adjustment system and power distribution system can keep the corn mill machine working in the best state.

- It can also process rice, wheat, sorghum, and other miscellaneous grains, and the final output has a bright color with high cleanliness, saving labor and time.

Failure and solution during making corn grits

During the use of the corn grits making machine, we provide you with several possible solutions to problems.

Failure 1: Too much crushed corn

Causes

1. The spindle speed is too high or too low.

2. The feed plate feeds too fast, or the pressure at the discharge port is too high.

Solution

1. Adjust the speed within the specified range.

2. Reasonably adjust the feeding speed and control the pressure at the outlet.

Failure 2: The corn peeling is not clean

Causes

1. The output is too high.

2. The fan speed is low.

3. The screen cylinder is blocked.

Solution

1. Appropriately reduce output and reduce export pressure.

2. Increase the speed of the fan.

3. Clean the screen tube.

Failure 3: The uneven size of corn grits

Causes

1. The grinding head has not reached the running-in period.

2. The center of the grinding head is not adjusted.

3. The bearing is damaged.

Solution

1. Use 50 kg of bran to properly compress the grinding head for 1-2 hours of grinding.

2. Re-adjust or replace the grinding head.

3. Replace the bearing.

Failure 4: Too much inner skin and impurities in the corn grits

Causes

1. The peeling machine is not clean.

2. The air volume is too small.

Solution

1. Improve corn removal rate.

2. Increase the fan speed or open the air adjustment flap.

The Customer Case

Maize grits making machines have always been the favorite machines for customers from all over the world. At present, our corn grits making machines have been sold to the Philippines, Indonesia, Nigeria, Botswana, the United States, Morocco, Canada, etc.

Every time we ship, we have specialized personnel to supervise to ensure that the machine is intact in the hands of the customer. And our packaging method is good in that the machine is free of wear during transportation.

Last week we packed and shipped the corn grits to our Somalia customer. The customer needed a corn grits machine to start a small grits workshop. And after communicating for some time, we learned that the customer needed a T1 model grits machine. The machine is inexpensive, fully functional, and can meet the customer’s needs. Here are the pictures of the corn grits making machine’s packaging and delivery.

If you are interested in our corn grits making machine, please feel free to contact us, we recommend the right machine for you. We have many years of experience and the most competitive machines, which is the best choice for you!