Machine de fabrication et de fraisage de maïs, de gruau de maïs

Machine de fabrication et de fraisage de maïs, de gruau de maïs

Rectifieuse de maïs/fraiseuse de gruau de maïs

Aperçu des fonctionnalités

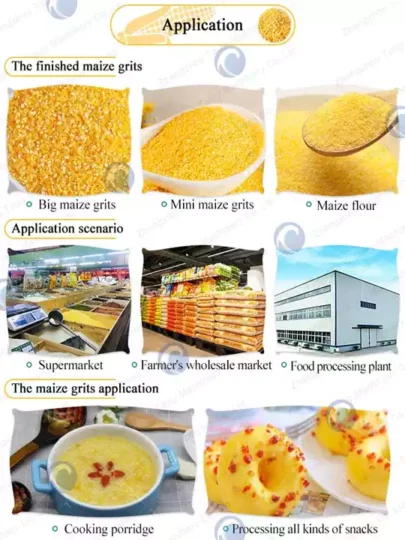

Machine de fabrication de gruau de maïs est l'équipement qui peut transformer les grains de maïs en gruau de maïs et en farine de maïs. De nos jours, le gruau de maïs et la farine de maïs sont les formes de maïs les plus couramment consommées dans la vie quotidienne des gens. Parce que le maïs moulu est facile à manger et à digérer et peut être transformé en denrée alimentaire. Par conséquent, la machine à gruau de maïs est devenue populaire sur le marché.

Pour répondre aux besoins des différents clients, nous avons produit cinq modèles différents de fraiseuses à grains de maïs. Ils diffèrent en termes de puissance, d’apparence et de fonction. Les gens peuvent utiliser le batteuse de maïs traiter d'abord le maïs, puis procéder à une transformation ultérieure.

Introduction de la fraiseuse à gruau de maïs

Les machines à éplucher et à fabriquer du gruau de maïs doivent éplucher le maïs, puis le transformer en trois formes différentes, à savoir du gros gruau de maïs, du petit gruau de maïs et de la farine de maïs.

Machine de fabrication de gruau de maïs peut effectuer le nettoyage, le pelage, l'élimination des germes, l'élimination des racines, l'élimination du nombril noir, le concassage, le broyage, le classement et le polissage du gruau de maïs en même temps. La machine peut compléter tous les processus pour produire différentes granulométries et farine de maïs de différentes mailles.

Le maïs séché avec une humidité inférieure à 12% a d'abord été placé dans la section d'épluchage. Ensuite, il passe dans la deuxième partie pour le broyage, en passant à travers un tamis à farine et un tamis à gruau pour obtenir de la farine de maïs et du gruau de différentes tailles.

Nous fabriquons cinq modèles de machines de fabrication de gruau de maïs, à savoir PH, C2, T1, PD2 et T3. Ces machines sont de structure compacte, simples à utiliser et économes en énergie, efficaces et durables.

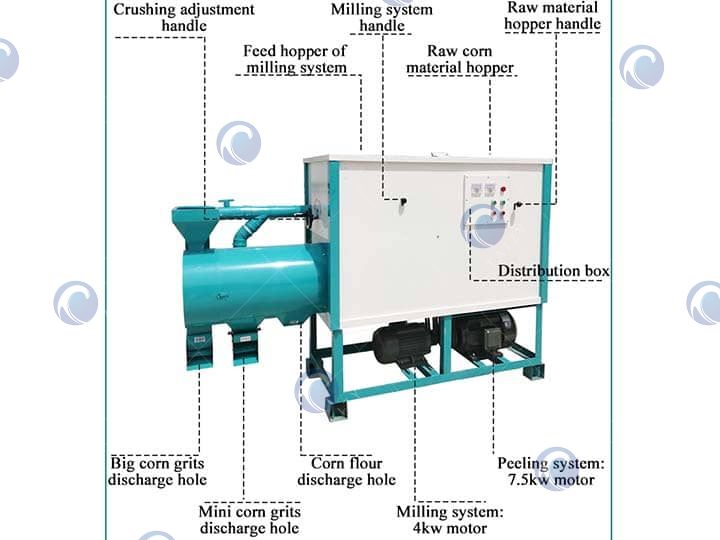

La structure principale de la machine de fabrication de gruau de maïs

Machines de fabrication de gruau de maïs disposent principalement d'un système de pelage, d'un système de production de gruau, d'un système de classification des produits finis, d'un système de dépoussiérage, d'un cadre et d'un système de distribution d'énergie.

Système de pelage

- Le système de pelage comprend un dispositif d'alimentation, un dispositif de cassage et de blanchiment des coques, un dispositif de séparation du son et un système de réglage automatique pour la décharge.

- Le dispositif d'alimentation comporte principalement une trémie d'alimentation, un siège de trémie et une plaque d'insertion. La trémie peut stocker une certaine quantité de maïs et faire entrer le maïs dans la salle d'épluchage par gravité. La porte d'entrée peut contrôler le débit des matériaux.

- Le dispositif d'épluchage comprend principalement le trou de décharge, le fuselage, le caisson de réduction, le ventilateur, le tendeur, la trémie à grains, le collecteur de son, etc.

Système de fabrication de gruau

Le système de fabrication de granulés est principalement composé d'une hélice, d'un embrayage, d'une poignée de concassage en continu, etc.

Système de classement des produits finis

Le maïs peut être divisé en trois manières selon différents degrés de transformation : grains de maïs, gruau de maïs et farine de maïs.

Système de dépoussiérage du réseau d'air

Il dispose de ventilateurs, de conduits d’air et de dépoussiéreurs.

Cadre

Il est composé d'acier d'angle et d'acier de canal de haute qualité internationale. Et nous y sommes parvenus grâce à de nombreux processus tels que la découpe, le chanfreinage, le soudage de précision, etc.

Le maïs est un aliment indispensable dans de nombreux pays. Le gruau de maïs et la farine de maïs peuvent non seulement être utilisés pour faire de la soupe, mais aussi pour préparer des aliments de base tels que le Fufu, le Ngima, le Sima, le Gima, le Posho, etc. De plus, le gruau de maïs peut également être transformé en aliments soufflés, très populaires. .

Principe de fonctionnement de la rectifieuse de maïs

Une fois que le maïs entre dans la salle de décorticage depuis la trémie, il se déplace vers la sortie sous la rotation et la poussée des nervures motrices. Dans la salle de pelage, en raison de la réduction progressive du volume de la salle de travail et de l'influence de la résistance de la rectifieuse de grains de maïs, la densité entre les grains diminue et la pression augmente en conséquence.

Ainsi, la compression et la friction du maïs dans le broyeur à maïs sont renforcées. Avec l'avancement continu du rouleau, le frottement et le décapage se poursuivent pour éliminer progressivement le maïs. Les grains de maïs et les peaux de son obtiennent l'effet de séparation automatique. Et enfin, le maïs pelé fini s'écoule par l'orifice de décharge. La peau du son est évacuée par l'autre sortie.

Processus de travail de la machine de fabrication de gruau de maïs

- Tout d’abord, placez les grains de maïs propres dans la trémie du broyeur, puis avancez dans le broyeur à embrayage de traction.

- Ils seront ensuite pelés et broyés, éliminant ainsi le 30% de l'enveloppe de maïs.

- Ensuite, le maïs concassé entre dans le système de classification et est séparé par trois tamis ronds. Ainsi, le maïs de formes différentes est finalement déchargé respectivement des trois sorties. Dans ce processus, les micro-peaux du gruau de maïs sont aspirées par l'action du vent à travers les ventilateurs pour obtenir du gruau fin. Et vous pouvez régler l'amortisseur pour déterminer la force du vent. Les micro-peaux soufflées par le ventilateur peuvent être récupérées dans des sacs.

Avant d'utiliser cette machine de fabrication de gruau de maïs, vous pouvez d'abord nettoyer les grains de maïs avec notre machine de nettoyage de grains, cliquez pour en savoir plus : Équipement de nettoyage de grains de maïs, nettoyeur de maïs à haute efficacité, à vendre.

Vidéo de travail de la machine à broyer le maïs

Spécifications du broyeur de gruau de maïs

| Modèle | ZX-T1 |

| Épluchage de maïs | 350-450kg |

| Faire du gruau de maïs | 1000 kg |

| Tension nominale | 380v |

| Pouvoir | 7,5 kW 4 pôles |

| Faire de la farine de maïs | 350 kg |

| Vitesse de broche | 1150 tr/min |

Quels sont les avantages d'une fraiseuse à maïs ?

- Une conception unique résout les difficultés techniques telles que l’élimination lente des impuretés.

- Equipé du système d'affichage actuel. Ainsi, vous pouvez voir la pression interne de la salle de travail et l'effet de pelage du maïs.

- Un système de réglage automatique et un système de distribution d'énergie nouvellement ajoutés peuvent maintenir le moulin à maïs dans le meilleur état possible.

- Il peut également traiter du riz, du blé, du sorgho et d'autres céréales diverses, et le résultat final a une couleur vive avec une grande propreté, ce qui permet d'économiser du temps et du travail.

Échec et solution lors de la fabrication du gruau de maïs

Lors de l'utilisation de la machine de fabrication de gruau de maïs, nous vous proposons plusieurs solutions possibles aux problèmes.

Échec 1 : Trop de maïs écrasé

Causes

1. La vitesse de broche est trop élevée ou trop faible.

2. La plaque d'alimentation avance trop vite ou la pression au niveau de l'orifice de décharge est trop élevée.

Solution

1. Ajustez la vitesse dans la plage spécifiée.

2. Ajustez raisonnablement la vitesse d’alimentation et contrôlez la pression à la sortie.

Échec 2 : l'épluchage du maïs n'est pas propre

Causes

1. La sortie est trop élevée.

2. La vitesse du ventilateur est faible.

3. Le cylindre du tamis est bloqué.

Solution

1. Réduire de manière appropriée la production et réduire la pression sur les exportations.

2. Augmentez la vitesse du ventilateur.

3. Nettoyez le tube de tamis.

Échec 3 : La taille inégale du gruau de maïs

Causes

1. La tête de meulage n’a pas atteint la période de rodage.

2. Le centre de la tête de meulage n'est pas ajusté.

3. Le roulement est endommagé.

Solution

1. Utilisez 50 kg de son pour comprimer correctement la tête de broyage pendant 1 à 2 heures de broyage.

2. Réajustez ou remplacez la tête de meulage.

3. Remplacez le roulement.

Échec 4 : Trop de peau interne et d'impuretés dans le gruau de maïs

Causes

1. La machine à éplucher n'est pas propre.

2. Le volume d’air est trop petit.

Solution

1. Améliorer le taux d’élimination du maïs.

2. Augmentez la vitesse du ventilateur ou ouvrez le volet de réglage de l'air.

Le cas client

Les machines de fabrication de gruau de maïs ont toujours été les machines préférées des clients du monde entier. À l'heure actuelle, nos machines de fabrication de gruau de maïs ont été vendues aux Philippines, en Indonésie, au Nigéria, au Botswana, aux États-Unis, au Maroc, au Canada, etc.

Chaque fois que nous expédions, nous supervisons un personnel spécialisé pour garantir que la machine est intacte entre les mains du client. Et notre méthode d'emballage est bonne dans la mesure où la machine est exempte d'usure pendant le transport.

La semaine dernière, nous avons emballé et expédié le gruau de maïs à notre Somalie client. Le client avait besoin d'une machine à gruau de maïs pour démarrer un atelier de petits gruaux. Et après avoir communiqué pendant un certain temps, nous avons appris que le client avait besoin d'une machine à granuler modèle T1. La machine est peu coûteuse, entièrement fonctionnelle et peut répondre aux besoins du client. Voici les photos de l’emballage et de la livraison de la machine de fabrication de gruau de maïs.

Si vous êtes intéressé par notre machine de fabrication de gruau de maïs, n'hésitez pas à nous contacter, nous vous recommandons la machine qui vous convient. Nous avons de nombreuses années d'expérience et les machines les plus compétitives, ce qui est le meilleur choix pour vous !

Hot Product

Équipement de semoir de graines d'arachide à 4 rangées

Cet article concerne la cacahuète à 4 rangs…

Machine d'irrigation par aspersion | Système d'irrigation | Irrigateur

La machine d’irrigation par aspersion fait référence à l’équipement utilisé…

Machine de cueillette d'arachides, machine de cueillette d'arachides à haute efficacité

La machine à cueillir des cacahuètes consiste à cueillir les cacahuètes…

Petite batteuse éplucheuse de maïs | Mini batteuse de maïs

Il s'agit d'une petite batteuse éplucheuse de maïs.…

Trancheuse à manioc /trancheuse à patates douces

La trancheuse à manioc peut éplucher le manioc puis le couper en…

Machine de récolte de maïs de maïs

La machine de récolte de maïs est utilisée pour récolter…

Machine à épierrer le riz et le blé | Machine d'élimination des impuretés de la pierre

La machine à épierrer le riz est principalement utilisée dans le grain…

Planteur de graines de maïs d'arachide à main à essence

Les jardinières à main à essence sont basées sur les jardinières à main traditionnelles…

Mélangeuse d'aliments horizontale TMR à vendre | Mélangeuse à fourrage | Mélangeur de purée

Le mélangeur d'aliments/mélangeur de fourrage horizontal est principalement utilisé…

Comments are closed.