Maíz, sémola de maíz que hace y fresadora

Maíz, sémola de maíz que hace y fresadora

Máquina trituradora de maíz/fresadora de sémola de maíz

Funciones de un vistazo

Máquina para hacer sémola de maíz es el equipo que puede procesar granos de maíz en sémola de maíz y harina de maíz. Hoy en día, la sémola de maíz y la harina de maíz son las formas más comunes de maíz que se consumen en la vida diaria de las personas. Porque el maíz molido es fácil de comer y digerir y puede procesarse aún más para convertirlo en alimento. Por lo tanto, la máquina de sémola de maíz se ha vuelto popular en el mercado.

Para satisfacer las necesidades de diferentes clientes, hemos producido cinco modelos diferentes de fresadoras de arena de maíz. Se diferencian en términos de rendimiento, apariencia y función. La gente puede utilizar el maquina trilladora de maiz procesar primero el maíz y luego proceder a su posterior procesamiento.

Introducción de la fresadora de sémola de maíz.

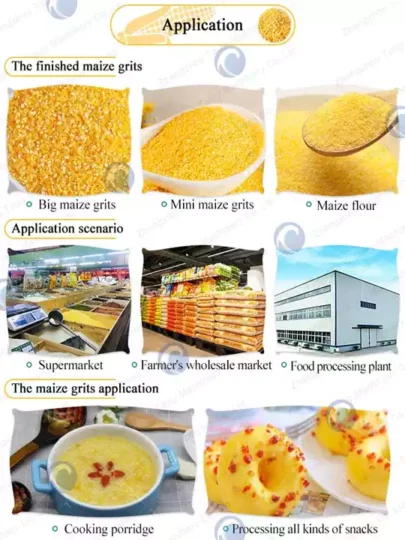

Las máquinas para pelar y fabricar sémola de maíz pelan el maíz y luego lo procesan en tres formas diferentes: sémola de maíz grande, sémola de maíz pequeña y harina de maíz.

Máquina para fabricar sémola de maíz Puede completar la limpieza, pelado, eliminación de gérmenes, eliminación de raíces, eliminación del ombligo negro, trituración, molienda, clasificación y pulido de sémola de maíz al mismo tiempo. La máquina puede completar todos los procesos para producir diferentes tamaños de grano y harina de maíz de diferentes mallas.

Primero se colocó maíz seco con menos de 12% de humedad en la sección de pelado. Luego pasa a la segunda parte para moler, pasando por un tamiz de harina y un tamiz de sémola para obtener harina de maíz y sémola de diferentes tamaños.

Fabricamos cinco modelos de máquinas para fabricar sémola de maíz, son PH, C2, T1, PD2 y T3. Estas máquinas tienen una estructura compacta, un funcionamiento sencillo, ahorran energía, son eficientes y duraderas.

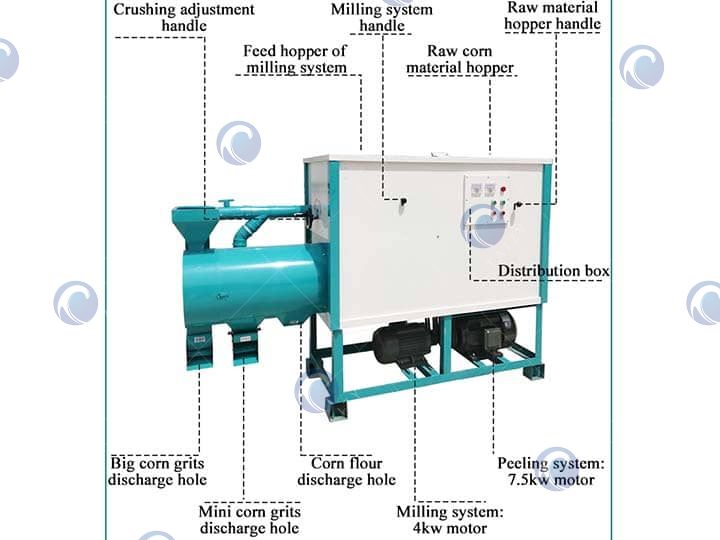

La estructura principal de la máquina para fabricar sémola de maíz.

Máquinas para hacer sémola de maíz Tienen principalmente un sistema de pelado, un sistema de producción de sémola, un sistema de clasificación de productos terminados, un sistema de eliminación de polvo, un marco y un sistema de distribución de energía.

Sistema de pelado

- El sistema de pelado incluye un dispositivo de alimentación, un dispositivo para romper y blanquear la cáscara, un dispositivo para separar el salvado y un sistema de ajuste automático de la descarga.

- El dispositivo de alimentación tiene principalmente una tolva de alimentación, un asiento de tolva y una placa de inserción. La tolva puede almacenar una cierta cantidad de maíz y hacer que el maíz ingrese a la sala de pelado por gravedad. La compuerta de entrada puede controlar el caudal de los materiales.

- El dispositivo de pelado incluye principalmente el orificio de descarga, el fuselaje, la caja reductora, el ventilador, el tensor, la tolva de granos, el recolector de salvado, etc.

Sistema de fabricación de sémola

El sistema de producción de arena se compone principalmente de la hélice, el embrague, el mango triturador continuo, etc.

Sistema de clasificación de producto terminado.

El maíz se puede dividir en tres formas según diferentes grados de procesamiento: granos de maíz, sémola de maíz y harina de maíz.

Sistema de eliminación de polvo de la red aérea.

Cuenta con ventiladores, ductos de aire y recolectores de polvo.

Marco

Está compuesto de acero en ángulo y canal de acero de alta calidad internacional. Y lo logramos a través de muchos procesos como corte, biselado, soldadura de precisión, etc.

El maíz es un alimento indispensable en muchos países. La sémola de maíz y la harina de maíz no solo se pueden usar para hacer sopa sino también para preparar alimentos básicos como Fufu, Ngima, Sima, Gima, Posho, etc. Además, la sémola de maíz también se puede procesar para obtener alimentos inflados, lo cual es muy popular. .

Principio de funcionamiento de la máquina trituradora de maíz.

Después de que el maíz ingresa a la sala de descascarado desde la tolva, se mueve hacia la salida bajo la rotación y el empuje de las nervaduras propulsoras. En la sala de pelado, debido a la reducción gradual del volumen de la sala de trabajo y la influencia de la resistencia de la máquina trituradora de arena de maíz, la densidad entre el maíz disminuye y la presión aumenta en consecuencia.

Por lo tanto, se fortalece la compresión y la fricción del maíz en el molino de maíz. Con el avance continuo del rodillo se continúa con la fricción y el decapado para retirar gradualmente el maíz. Los granos de maíz y la piel del salvado logran el efecto de separación automática. Y finalmente, el maíz pelado terminado sale a través del puerto de descarga. La piel de salvado se descarga por la otra salida.

Proceso de trabajo de la máquina para fabricar sémola de maíz.

- En primer lugar, coloque los granos de maíz limpios en la tolva del triturador y luego avance a través del triturador del embrague de tracción.

- Luego se pelarán y triturarán, retirando 30% de la hoja de maíz.

- Luego el maíz triturado ingresa al sistema de clasificación y es separado por tres cribas redondas. Entonces, el maíz con diferentes formas finalmente se descarga respectivamente de las tres salidas. En este proceso, las micropiel de la sémola de maíz son succionadas por la acción del viento a través de los ventiladores para obtener sémola fina. Y puedes ajustar el amortiguador para determinar la fuerza del viento. Las micropiels sopladas por el ventilador se pueden recoger en bolsas.

Antes de usar esta máquina para hacer sémola de maíz, primero puede limpiar los granos de maíz con nuestra máquina limpiadora de granos, haga clic para obtener más información: Equipo de limpieza de granos limpiador de maíz de alta eficiencia a la venta.

Video de trabajo de la máquina trituradora de maíz.

Especificaciones del molinillo de sémola de maíz.

| Modelo | ZX-T1 |

| pelado de maiz | 350-450 kilos |

| Hacer sémola de maíz | 1000 kilos |

| Tensión nominal | 380v |

| Fuerza | 7,5 kw 4 polos |

| hacer harina de maíz | 350 kilos |

| Eje de velocidad | 1150 rpm |

¿Qué ventajas tiene una fresadora de maíz?

- El diseño único resuelve dificultades técnicas como la lenta eliminación de impurezas.

- Equipado con el sistema de visualización actual. Así, se puede ver la presión interna de la sala de trabajo y el efecto de pelado del maíz.

- Un sistema de ajuste automático y un sistema de distribución de energía recientemente agregados pueden mantener el molino de maíz funcionando en el mejor estado.

- También puede procesar arroz, trigo, sorgo y otros granos diversos, y el resultado final tiene un color brillante con alta limpieza, lo que ahorra mano de obra y tiempo.

Fallo y solución durante la elaboración de sémola de maíz.

Durante el uso de la máquina para fabricar sémola de maíz, le brindamos varias soluciones posibles a los problemas.

Fallo 1: Demasiado maíz triturado

Causas

1. La velocidad del husillo es demasiado alta o demasiado baja.

2. La placa de alimentación avanza demasiado rápido o la presión en el puerto de descarga es demasiado alta.

Solución

1. Ajuste la velocidad dentro del rango especificado.

2. Ajuste razonablemente la velocidad de alimentación y controle la presión en la salida.

Fallo 2: La cáscara del maíz no está limpia

Causas

1. La salida es demasiado alta.

2. La velocidad del ventilador es baja.

3. El cilindro de la criba está bloqueado.

Solución

1. Reducir adecuadamente la producción y reducir la presión exportadora.

2. Aumente la velocidad del ventilador.

3. Limpiar el tubo de la pantalla.

Fallo 3: El tamaño desigual de la sémola de maíz

Causas

1. El cabezal rectificador no ha llegado al período de rodaje.

2. El centro del cabezal rectificador no está ajustado.

3. El rodamiento está dañado.

Solución

1. Utilice 50 kg de salvado para comprimir adecuadamente el cabezal de molienda durante 1 a 2 horas de molienda.

2. Vuelva a ajustar o reemplace el cabezal de molienda.

3. Reemplace el rodamiento.

Fallo 4: Demasiada piel interna e impurezas en la sémola de maíz

Causas

1. La peladora no está limpia.

2. El volumen de aire es demasiado pequeño.

Solución

1. Mejorar la tasa de eliminación de maíz.

2. Aumente la velocidad del ventilador o abra la trampilla de ajuste del aire.

El caso del cliente

Las máquinas para fabricar sémola de maíz siempre han sido las favoritas de clientes de todo el mundo. En la actualidad, nuestras máquinas para fabricar sémola de maíz se han vendido a Filipinas, Indonesia, Nigeria, Botswana, Estados Unidos, Marruecos, Canadá, etc.

Cada vez que realizamos un envío, contamos con personal especializado que supervisa y garantiza que la máquina esté intacta en manos del cliente. Y nuestro método de embalaje es bueno porque la máquina no sufre desgaste durante el transporte.

La semana pasada empacamos y enviamos sémola de maíz a nuestro cliente de Somalia. El cliente necesitaba una máquina de sémola de maíz para iniciar un pequeño taller de sémola. Y después de comunicarnos por un tiempo, supimos que el cliente necesitaba una máquina de arena modelo T1. La máquina es económica, completamente funcional y puede satisfacer las necesidades del cliente. Aquí están las imágenes del embalaje y entrega de la máquina para fabricar sémola de maíz.

Si está interesado en nuestra máquina para fabricar sémola de maíz, no dude en contactarnos, le recomendamos la máquina adecuada para usted. Contamos con muchos años de experiencia y las máquinas más competitivas, ¡cuál es la mejor opción para usted!