Vida Yağı Presi Fıstık Susam Yağ Tohumu Çıkarma Ekipmanı

Vida Yağı Presi Fıstık Susam Yağ Tohumu Çıkarma Ekipmanı

Yağ çıkarma ekipmanı | Otomatik yağ presi

Özellikler Genel Bakış

Otomatik vida yağı presi, verimli ve enerji tasarruflu bir yağ çıkarma ekipmanıdır, küçük ve orta ölçekli yağ değirmenleri ve aile atölyelerinde yaygın olarak kullanılır, yağ dönüşüm oranı -P arasındadır.

Geleneksel yağ çıkarma yöntemine kıyasla, bu ekipmanın yağ verimi %4 ila %6 artmış ve enerji tüketimi yaklaşık ` azalmıştır, bu da üretim verimliliğini ve ekonomik faydaları önemli ölçüde artırır.

Bu serideki yağ presleri kullanımı kolaydır, küçük alan kaplar ve çeşitli yağ bitkilerinin sıcak ve soğuk preslenmesine uygundur. Fıstık, soya, susam, hardal tohumu vb. 30'dan fazla yağ tohumu için uygundur. Kuru kekin kalan yağı oranı %0.5-3.5 arasındadır ve tek makinenin üretim kapasitesi 15kg/h ile 550kg/h arasındadır.

Farklı üretim gereksinimlerine göre, 6YL-60, 6YL-70, 6YL-80, 6YL-100, 6YL-125 vb. çeşitli modeller mevcuttur ve kullanıcıların çeşitli ihtiyaçlarını karşılar.

Satışta olan vida yağı presi makinesi

Otomatik vida yağı presi farklı malzemelere göre farklı sıcaklıklar ayarlanabilir ve vakum filtrasyon yapabilir.

Kolu çevirerek, insanların malzemeyi sıkmak için gereken basıncı ayarlayabilirler. Aynı zamanda, farklı basınçlar ile sıkılan yağ miktarı ve kek kalınlığı da değişir.

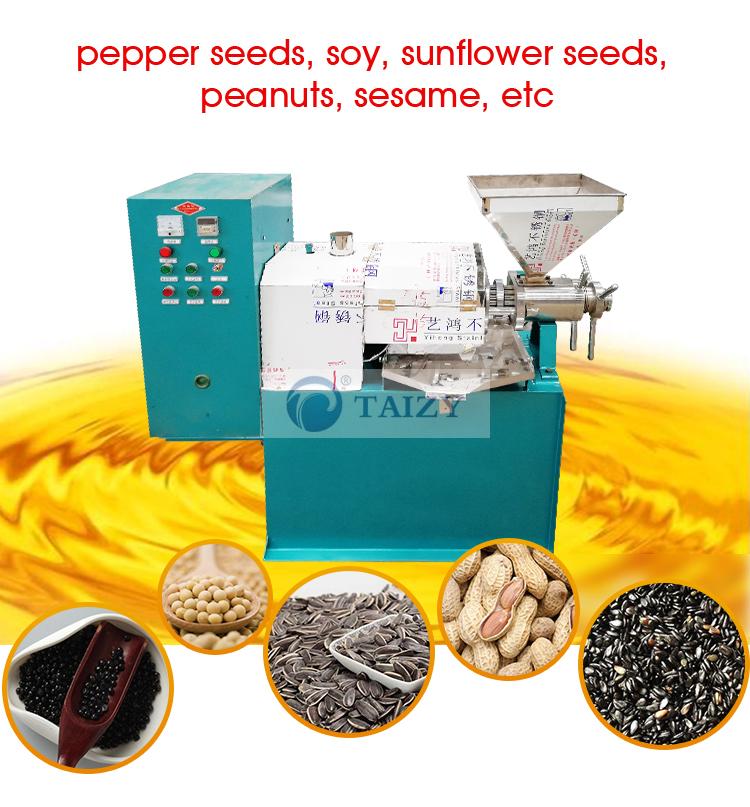

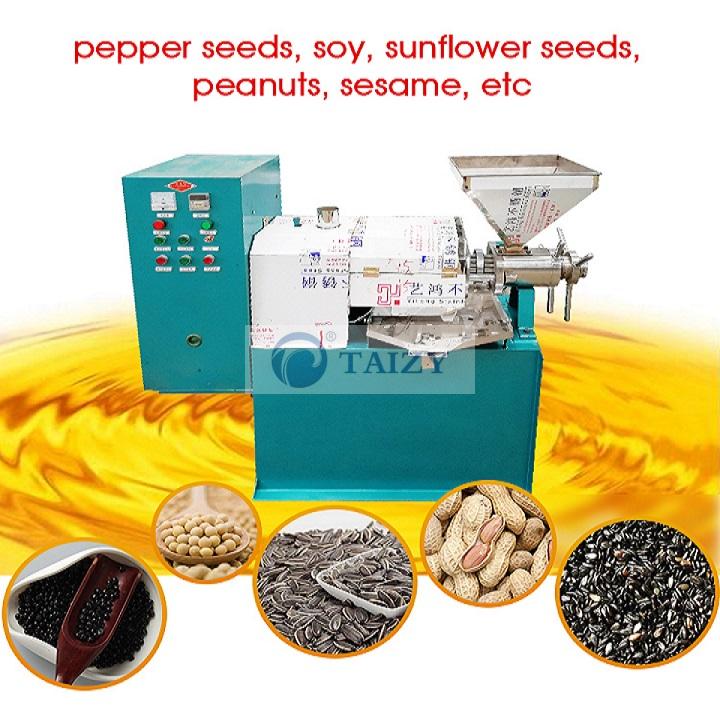

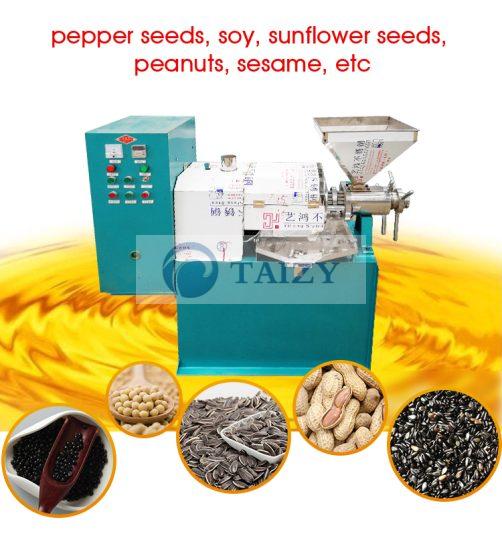

Vida yağı presi uygun malzemeler

Vida yağı presi makinemiz yer fıstığı, keten, susam, hardal tohumu, ayçiçeği, pamuk tohumu, soya, ceviz, biber tohumu, tung tohumu, hint yağı, badem vb. için uygundur.

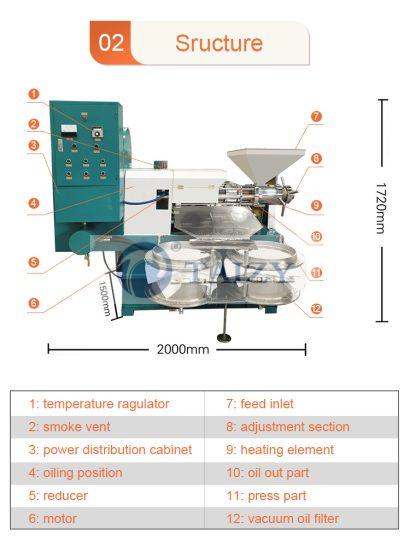

Vida presi yapısının yapısı

Vida yağı presi yapısında sıcaklık regülatörü, duman çıkış, toz dağıtım kabini, yağlama konumu, redüktör, motor, besleme girişi, ayar bölmesi, ısıtıcı eleman, yağ çıkış bölümü, pres bölümü, vakum yağı filtresi vb. bulunur.

Vida yağı çıkarıcı çalışma prensibi

Vida yağı presi makinesinde, ham maddeler hoperden pres odasına girer. Daha sonra, vida tarafından içeri itilerek preslenirler.

Yüksek basınç ve sürtünme, malzeme, vida ve odacık arasında göreceli hareket yaratır ve ısı üretir, bu da yağ çıkarma sürecine yardımcı olur.

Vida çapının artması ve azalan diş aralığı malzemeyi öne ve dışarı iter. Sürtünme ısısı proteinleri denatüre eder, plastisiteyi artırır ve viskoziteyi azaltır, böylece yağ verimini artırır ve yağın deliklerden akmasını sağlar.

Vida pres yağı çıkarıcı parametreleri

| Model | 6YL-60 | 6YL-70 | 6YL-80 | 6YL-100 | 6YL-125 |

| Vida çapı(mm) | Φ55 | Φ65 | Φ80 | Φ100 | Φ125 |

| Vida dönüş hızı(r/dak) | 64 | 38 | 35 | 37 | 34 |

| Ana güç(kw) | 2.2 | 3 | 4 | 7.5 | 15 |

| Vakum pompası gücü(kw) | 0.75 | 0.75 | 0.55 | 0.75 | 0.75 |

| Isıtma gücü(kw) | 0.9 | 1.8 | 2.2 | 3 | 3.75 |

| Kapasi̇tėt(kg/h) | 40-60 | 50-70 | 80-120 | 150-230 | 300-350 |

| Ağırlık(kg) | 240 | 280 | 880 | 1100 | 1400 |

| Boyut(mm) | 1200*480*1100 | 1400*500*1200 | 1700*110*1600 | 1900*1200*1300 | 2600*1300*2300 |

Vida tohum çıkarma makinesi avantajları

- Yüksek yağ verimi: eski ekipmanlara kıyasla, yağ verimi %2-3 artabilir. İşlenen her 100 pound fıstıktan ortalama 2-6 pound yağ elde edilebilir.

- Enerji tasarrufu ve çevre dostu: aynı çıktı altında @ elektrik tasarrufu sağlar.

- İş gücünden tasarruf ve yüksek verimlilik: aynı çıktı altında ` tasarruf sağlar, 1-2 kişi işletilebilir.

- Geniş uygulama alanı: bir makine çok amaçlıdır, 30'dan fazla yağ bitkisini presleyebilir (örneğin fıstık, susam, ayçiçeği, pamuk tohumu, soya vb.).

- Saf yağ: kalıntı vakumla filtrelenir, yağ kalitesi saf ve hijyenik karantina standardına uygundur.

- Küçük zemin alanı: pres atölyesi sadece 10-20 metrekareye ihtiyaç duyar ve üretim talebini karşılar.

- Akıllı sıcaklık kontrolü: kızılötesi sıcaklık kontrol sistemi kullanılır, presleme sıcaklığı ve nem otomatik olarak kontrol edilir, yağ molekülleri doğrudan yumuşatılır ve aktive edilir, ve yağ verimi büyük ölçüde artırılır.

- Yüksek verimli filtrasyon: çok aşamalı hassas filtrasyon cihazı kullanılarak yağ filtrasyon basıncı ve ham yağ sıcaklığı artırılır, yağ kalitesi daha saf ve filtrasyon hızı hızlıdır.

Vida yağı değirmeni kullanım talimatları

- Kullanmadan önce bağlantı elemanlarını kontrol edin, gevşek olmadıklarından emin olun; kolu ve kasnağı elle çevirerek işlemin esnek ve anormal ses olmadığını kontrol edin.

- Redüktörü 30# yağı ile doldurun. Makineyi çalıştırmadan önce güvenli bir şekilde topraklayın.

- Makineyi üç fazlı dört telli güç kaynağına bağlayın ve makineyi açtıktan sonra mil saat yönünün tersine dönmelidir.

- Termostatı, yağ oranına göre 120°C-160°C arasında ayarlayın, ana makinenin ısıtıcı anahtarını açın ve makineyi ön ısıtın.

- Yeni makineyi kurduktan sonra, 4-8 saatlik bir çalışma süresi gerekir: Hoperden kuru yağ kekini yavaşça koyun ve tekrar tekrar presleyerek pres odasını cilalayın.

- Besleme malzemesini eşit tutun, malzemenin kırılmasını veya çok fazla malzeme olmasını önleyin, makine normal yüklü, düzgün çalışıyor, sesli ve ritmik.

- Makineyi durdurmadan önce beslemeyi durdurun, küçük miktarda kek kalıntısı koyun, pres odasındaki kalan malzemenin boşaltılmasını bekleyin ve kek çıkışı durduktan sonra makineyi durdurun.

- Makineyi durdurduktan sonra, ayar vidasını saat yönünün tersine 1-3 tur çevirin ve sonunda güç kaynağını kesin.

Fabrikamız, hidrolik yağı presleri ( Yağ Çıkarma Makinesi |Vida Yağı Presi|Hidrolik Yağ Değirmeni ) gibi diğer türlerde yağı presleri de üretmektedir. İlgileniyorsanız, sağdaki formu doldurun ve ham malzemenizi ve özel ihtiyaçlarınızı bize bildirin. Size uygun önerilerde bulunacağız ve yağ presleme işinizin sorunsuz çalışmasını sağlayacağız.