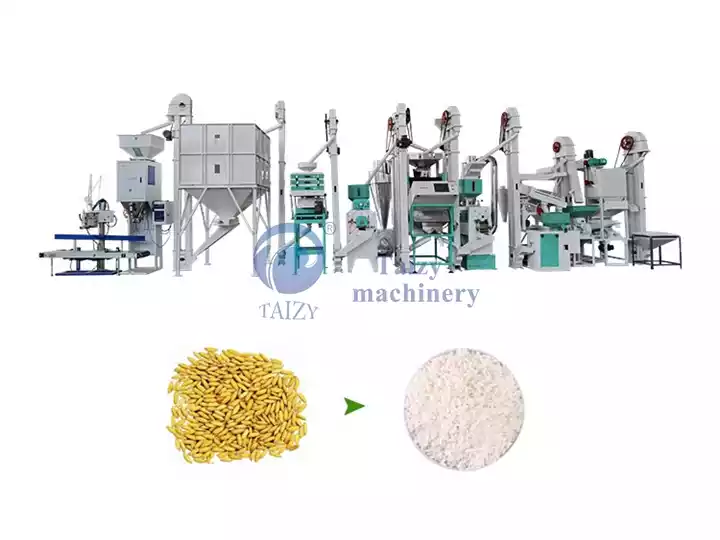

The rice milling plant machine unit is an efficient, economical, and easy-to-operate solution for rice processing. The equipment integrates de-hybridization, destoning, rice polishing, and grading in one unit, featuring a compact structure and a small footprint.

With a daily output of 600-800 kilograms, it can efficiently process paddy into high-quality rice that is white, free of impurities, and with a broken rice rate of less than 1%, which can be sold directly into supermarkets or food processing plants.

The production line is widely exported to Thailand, Vietnam, Nigeria, and other countries, well-received by users, and has established long-term cooperation.

It is especially suitable for small grain processing plants, rural cooperatives, and entrepreneurial projects. In addition, the whole machine is guaranteed for 2 years, which makes the use more at ease.

成套碾米机组 优点

- The equipment integrates multiple processes such as hulling, de-stoning, screening, polishing, etc. and is multi-purpose in one machine.

- The polishing rate is more than 80%, the broken rice rate is controlled within 1%, and the finished rice is full in appearance and good in selling.

- Equipped with vibrating screen and de-stoning device, effectively removing stones, weeds, dust and other impurities in the rice.

- The gravity sieve operates at a fast speed, with high screening precision, and the whole set of process is basically automated, saving labor cost.

- Low noise, no dust pollution in the process of rice production; low power consumption, more energy-saving operation.

- Equipped with crushing device, the rice husk can be crushed as feed, to enhance the utilization rate of resources.

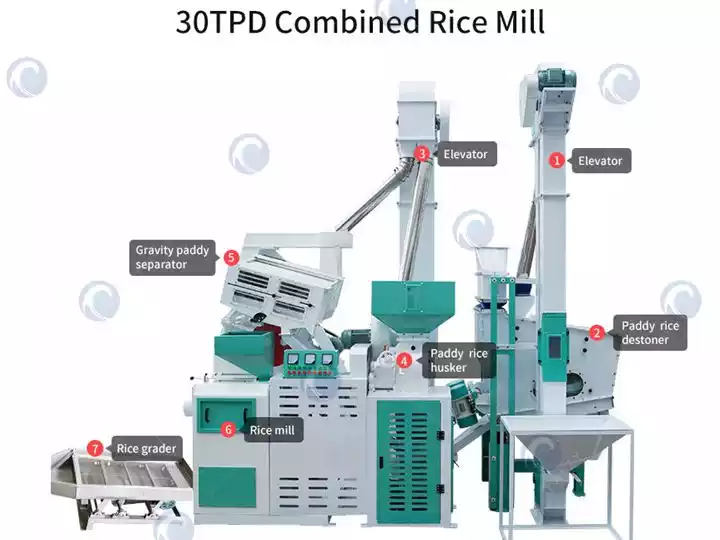

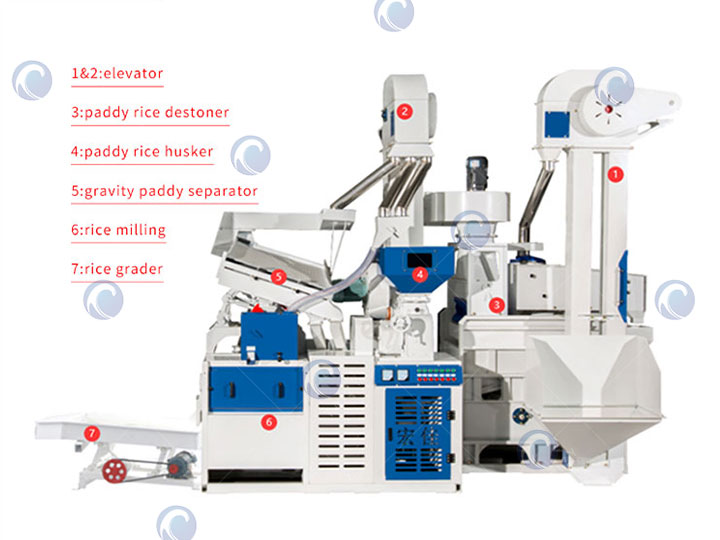

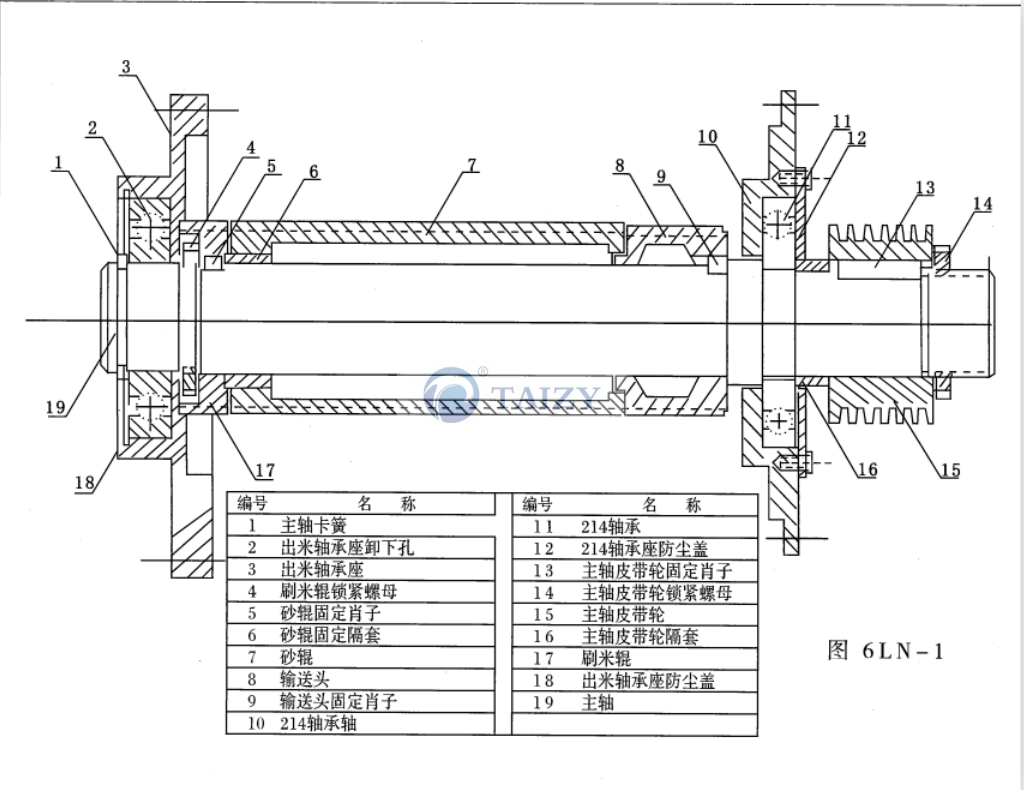

结构 碾米机

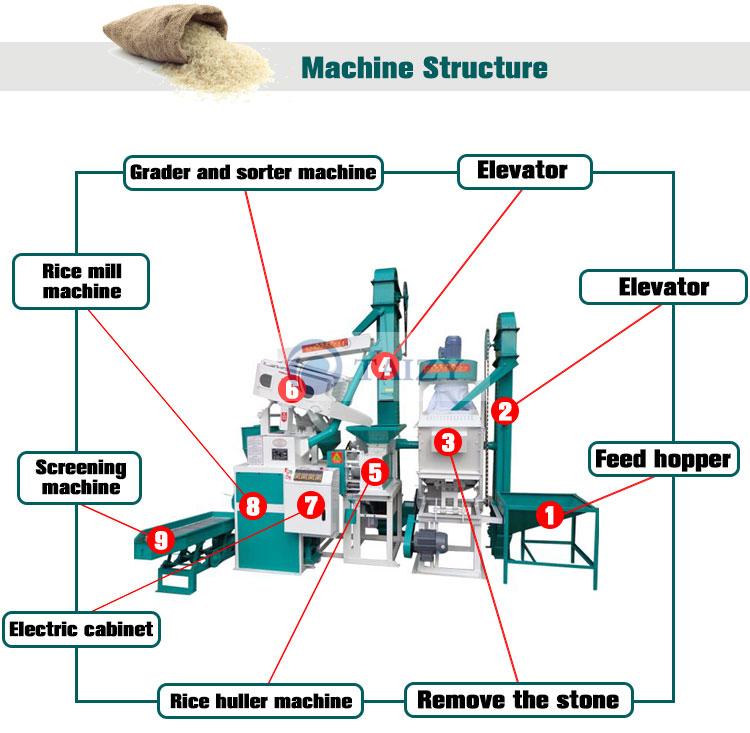

该碾米机主要由进料斗、米提升机、去石部分、砻谷部分、分级机、分选机、电气柜、筛选机等组成。

砻谷机 技术参数

Different sizes and volumes of production lines have different technical parameters. When purchasing, you have a variety of choices. Please consider your budget and production expectations, and so on.

| 容量 | 600-700公斤/小时 |

| 铣削率 | 71% |

| 总功率(不含破碎机) | 19.25千瓦 |

| 总功率(不含破碎机) | 26.26千瓦 |

| 方面 | 3000*2600*2900毫米 |

| 规格 | 功能 |

| 1-米斗 | 进口 |

| 2-单葫芦 | Lifting rice to suction gravity stone remover from a dust belt. |

| 3吸重力去石器 | Remove stone and straw from rice. |

| 4-自动脱壳机 | 将稻米去掉外皮,将米变成糙米。 |

| 5-双葫芦 | 他们都是承包商。控制各电机的启动。 |

| 6-重力筛 | 将大米与糙米完全分离。 |

| 7-配电箱 | 他们都是承包商。控制各电机的启动。 |

| 8-负压碾米机 | Whitening and polishing brown rice. |

| 9-碎米分级筛 | Separating broken rice from finished rice. |

| 10-研磨机 | Crushed chaff and rice bran. |

砻谷机电机型号

| 电机型号 | 电机配套件 | |

| 0.75KW-6级(960转/分) | 6-重力屏(一) | 5-双葫芦(一台) |

| 1.1KW-4级(1420转/分) | 三吸式重力去石机(小电机去石)(一台) | |

| 1.1KW-2级(2800转) | 三吸式重力去石机(石扇小电机)(一台) | |

| 22KW-4级(1460转/分) | 如果客户不需要10台破碎机。 8台负压碾米机和4台自动砻谷机,共用一台15千瓦电机。 | |

| 15KW-4级(1460转) | 如果客户不需要10台破碎机。 8台负压碾米机和4台自动砻谷机,共用一台15千瓦电机。 | |

| 550W-4(1320 转/分钟) | 9-碎米分级筛(一) | |

| 整机总功率:26.25KW(粉碎机含10-)6电机 细麸型

19.25KW(10-粉碎机)6电机 麸皮型 | ||

| 机器长:3.3m,宽:2.6m,高:2.9m | ||

| The number of packages is 3. 总计:10.9 PartyLength*宽度*高音量:170*140*215 = 5.17190*98*135 = 2.5196*2.92*2.92*1.15 = 3.22主机都是组装的,机器托盘由铁制成,四个侧面是热压板。用户可以轻松使用它们。 |

技术参数

| 整机重量 | 900公斤 |

| 方面 | 3300×2750×2800毫米 |

| 重力屏 | 0.75KW-6级 |

| 双葫芦 | 0.75KW-6级 |

| 大米去石机吸风机 | 0.75KW-2级 |

| 大米去石机 | 1.1KW-4级 |

| 米筛(可选) | 0.37KW-4级 |

| 主机 | 15KW-4级/22KW-4级(带破碎) |

碾米机工艺流程

This rice grinding machine conveys the raw materials to the milling and gravity sieving section after removing impurities through an elevator.

The husk is blown out by the fan, the brown rice is milled into white rice, and the sifter then separates the broken rice, making the whole process efficient and clean.

- 将大米放入进料斗(1)。

- Elevator(2) conveys the rice into the rice destoner part(3) that removes the stones contained in the rice.

- 提升机(4)再次输送稻谷,然后稻谷落入砻谷部分(5),去除稻壳。

- Rice goes into the grader and sorter part(6), however, the rice with lightweight and bad quality will go into the rice huller part(5).

- Elevator(4) conveys this bad rice to the grader and sorter part again, which means bad quality rice will enter the rice huller part and elevator twice.

- 好的大米将直接进入碾米机部分(8)进行抛光。

- 精米进入筛分部(9),筛分部(9)剧烈振动,再次过滤碎米和杂质。

- 最后,从筛分部分的出口得到白米。

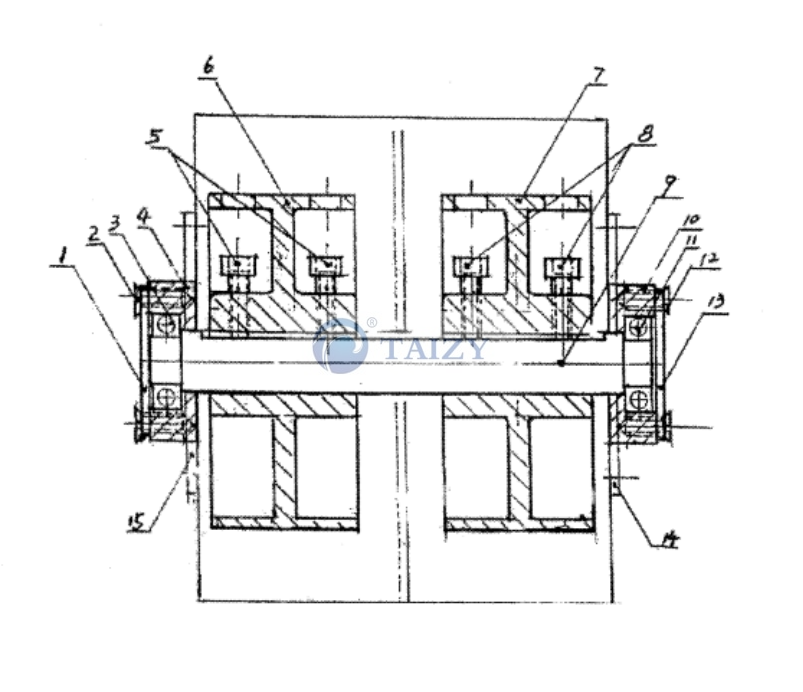

提升机下轴承如何拆卸

- 失去单(双)葫芦(14、15)底座轴承固定面板。

- 拆下轴承(1、13)两侧的防尘盖。

- 松开固定螺栓的平板。

- 用熨斗顶住左轴头,击打右侧。

- 拆下提升轴。

- 拆卸提升机下轴承的顺序。

- 15→14→2→1→12→13→5→8→9。

笔记:

- When the single (double) hoist is in use, it is necessary to pay attention to the tightness of the bucket belt.

- If the hoist is easy to block or can not discharge rice, please check if the bucket belt, upper or lower base is loose.

- Then check whether the pulley fixing bolt is loose(5)and whether the iron plate at the exit of the upper seat of the hoist slides downward.

解决方案:

- 拉紧提升机两侧皮带轮,以张紧斗带。

- 拧紧上、下卷扬皮带轮固定螺栓。

- Open the cover of the upper part of the hoist and push the iron plate at the exit upwards, then lock it. (The distance that the iron plate pushes upwards should be based on the standard that the bucket belt does not hit the iron plate.)

- 提升机堵塞后,提升机下座左侧或右侧有一个闸门,可通过闸门将提升机内的杂质拉出。

商用碾米机成功案例

We exported 5 sets of rice milling plant machines to Nigeria last year, and the customer feedback is good, and plans to continue purchasing.

A customer from the UK enquired about setting up a small-scale rice milling plant machine through our website.

After communicating with the sales manager via WhatsApp, we recommended a 20-ton capacity rice milling production line for him, and the order was finally placed successfully. The equipment has been packed and shipped.

常问问题

你们有多少种组合碾米生产线?

这个系列有10多个类型,每个类型都在这个系列的基础上增加了一些部分。

这一系列稻米加工厂机器的最大产能是多少?

最大产能100吨/天。

这种大型碾米机与其他类型的碾米机有什么区别?

这台稻米加工厂机器具有提升器、去石部分、破碎部分和筛选部分,这些在普通的稻米加工厂机器中是没有的。

机器安装、拆卸方便吗?

是的,如有需要,我们可以安排我们的技术人员帮助您安装。

破损率是多少?

稻米破碎率小于1%。

我们有不同型号的 碾米生产线 15吨至60吨。客户可以根据自己的需要进行选择。此外,我们还有 水稻和小麦脱粒机,可先将大米脱粒,然后用碾米机进行深加工。

If you are interested in our rice milling plant machines or would like to know more detailed information, please feel free to contact us for a full range of services. You are warmly welcome to visit our factory and experience the excellent performance of the rice milling unit for yourself.