功能一览

我们提供一年内免费更换的易损件。

提供终身在线技术支持。

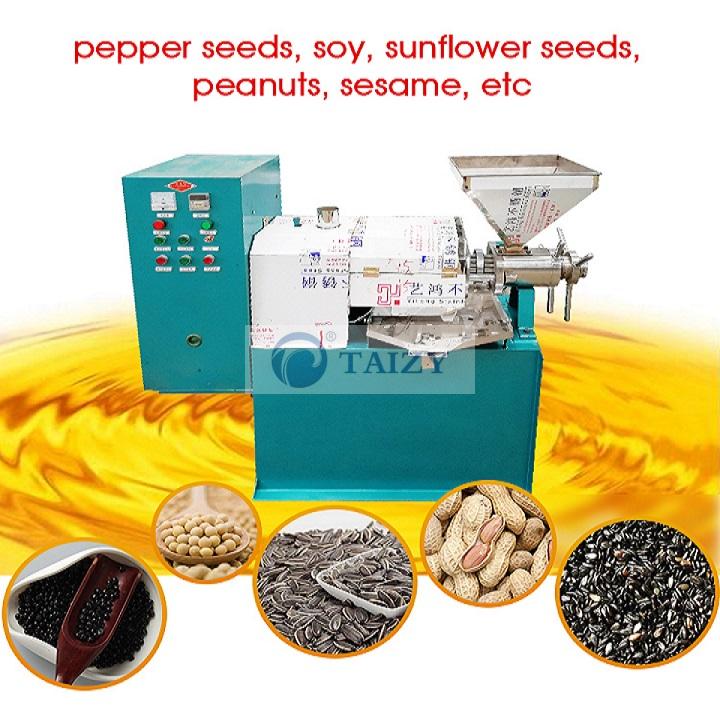

自动 螺旋油压机是一种高效节能的油提取设备,广泛应用于中小型油厂和家庭作坊,油转化率为20%-50%。

与传统油提取方法相比,该设备的油产率提高了4%至6%,能耗降低约60%,显著提高生产效率和经济效益。

本系列油压机操作简便,占地面积小,适用于各种油料的热冷压榨。适用于花生、大豆、芝麻、油菜籽等30多种油料作物。干饼残油率低至0.5%-3.5%,单机产能从15kg/h到550kg/h不等。

根据不同的生产需求,提供多种型号供选择,如6YL-60、6YL-70、6YL-80、6YL-100、6YL-125等,以满足用户的多样化需求。

热销螺旋油压机

自动螺旋油压机可以实现真空过滤。可以根据不同材料设置不同温度。

旋转手柄可以调节人们所需的挤压压力。不同压力下挤出的油量也不同,油饼的厚度也不同。

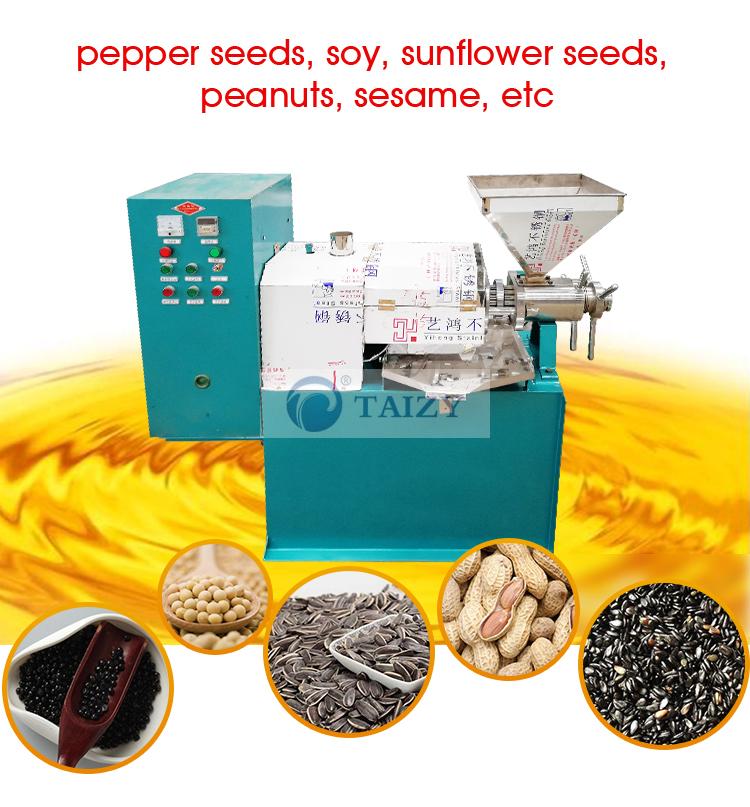

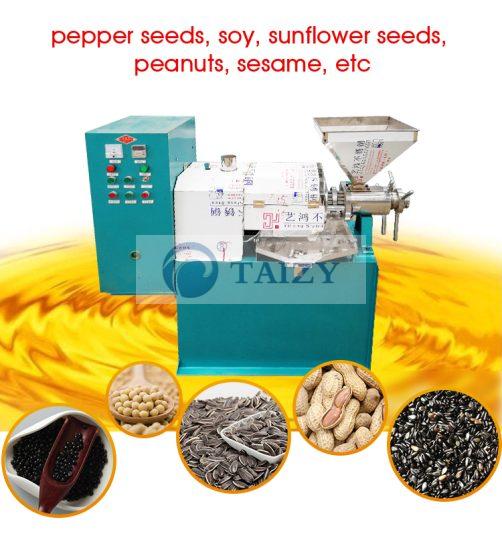

螺旋油压机适用材料

我们的螺旋油压机适用于花生、亚麻、芝麻、油菜籽、向日葵、棉籽、大豆、核桃、胡椒籽、桐籽、蓖麻、杏仁等多种油料作物。

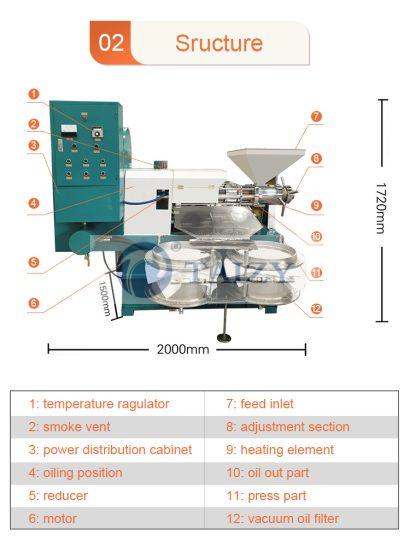

螺旋压榨油提取结构

螺旋油压机结构包括温度调节器、烟尘排放口、粉尘分配箱、加油位置、减速器、电动机、进料口、调节段、加热元件、出油部分、压榨部分、真空油过滤器等。

螺旋油提取机的工作原理

在螺旋油压机中,原料从料斗进入压榨腔,然后由螺旋向内推压。

材料之间的高压和摩擦、螺旋和腔体之间的相对运动产生热量,有助于油的提取过程。

螺旋直径逐渐增大,螺距逐渐减小,将物料向前推送和向外推送。摩擦生热有助于蛋白质变性、增加塑性、降低粘度,从而提高油产率,使油通过压榨缝隙流出。

螺旋压榨机参数

| 型号 | 6YL-60 | 6YL-70 | 6YL-80 | 6YL-100 | 6YL-125 |

| 螺旋直径(mm) | Φ55 | Φ65 | Φ80 | Φ100 | Φ125 |

| 螺旋转速(r/min) | 64 | 38 | 35 | 37 | 34 |

| 主功率(kw) | 2.2 | 3 | 4 | 7.5 | 15 |

| 真空泵功率(kw) | 0.75 | 0.75 | 0.55 | 0.75 | 0.75 |

| 加热功率(kw) | 0.9 | 1.8 | 2.2 | 3 | 3.75 |

| 容量(kg/h) | 40-60 | 50-70 | 80-120 | 150-230 | 300-350 |

| 重量(kg) | 240 | 280 | 880 | 1100 | 1400 |

| 尺寸(mm) | 1200*480*1100 | 1400*500*1200 | 1700*110*1600 | 1900*1200*1300 | 2600*1300*2300 |

螺旋油料提取机优势

- 高油脂产量:与旧设备相比,油脂产量可提高2-3个百分点。每处理100磅花生,平均可产出2-6磅油。

- 节能环保:在相同产量下节省40%的电力。

- 节省劳动力,高效:在相同产量下节省60%的劳动力,1-2人即可操作。

- 应用范围广:一机多用,可压榨30多种油料作物(如花生、芝麻、向日葵、棉籽、大豆等)。

- 纯油:残渣通过真空过滤,油质纯净,符合卫生检疫标准。

- 占地面积小:压榨车间仅需10-20平方米即可满足生产需求。

- 智能温控:采用红外温控系统,自动控制压榨温度和湿度,油分子直接软化激活,大大提高油产率。

- 高效过滤:采用多级精密过滤装置,提高油过滤压力和原油温度,油质更纯,过滤速度快。

螺旋油厂的使用说明

- 使用前检查紧固件,确保无松动;手动转动手柄和皮带轮,确保操作灵活,无异常噪音。

- 用30#机油填充减速器。启动前必须可靠接地。

- 将机器连接到三相四线电源,启动后应逆时针旋转主轴。

- 将恒温器调节至120°C-160°C(根据油的不同),开启主机的加热开关并预热机器。

- 安装新机器后,需要磨合4-8小时:慢慢将干油饼放入料斗,并反复压榨以抛光压榨室。

- 保持喂料均匀,避免料碎或料过多,机器正常加载,运行平稳,节奏有序。

- 停止前,停止喂料,加入少量饼残料,等待压榨腔内残余物排出后,再停止机器。

- 停止机器后,将调节螺钉顺时针旋转1-3圈,最后断开电源。

我厂生产其他类型的 油 压榨机,如液压油压榨机(油提取机 |螺旋油压榨机|液压油厂)。如有兴趣,可填写右侧表格,告诉我们您的原料和具体需求。我们将为您提供合适的建议,帮助您的油压榨业务顺利进行。

型号:6YZ-260

喂料直径:260毫米

加热线圈控温:70-100

压力:55兆帕

压榨时间:10分钟

产能(每次):10-12公斤

型号:2BHMF-6

种子箱容量:10kg*6

尺寸:2940×1900×1300毫米

行距:300-350毫米

种子间距:80-300毫米

产能:1.6-3.2亩/小时

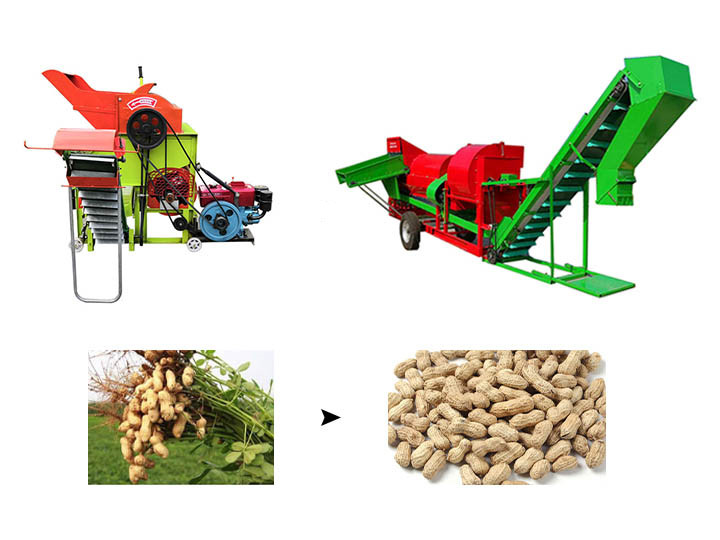

型号:5HZ-600

尺寸:1960*1500*1370毫米

重量:150公斤

功率:7.5千瓦电机,10马力柴油机

容量:800-1000公斤/小时

采摘率:>99%