Our factory has completed producing and delivering 5 sets of silage chopper crusher machines. The customer is from Madagascar, operating a large-scale integrated enterprise of beef cattle and dairy cattle breeding and feed processing.

Customer background and core requirements

- The customer’s local area is rich in bagasse, cassava stems and other high-fiber crop stalks, but the raw materials are coarse and hard.

- Traditional manual guillotine cutting efficiency is low and the loss rate is more than 30%, resulting in uneven fermentation of silage, nutritional value is difficult to release, restricting the effect of livestock fattening.

- Last year, the silage baling and wrapping machine purchased from our company has realized the sealed storage of large bales, but the direct baling of raw materials without crushing is easy to cause mold.

- Now it needs a matching silage chopper to carry out fine pre-treatment of raw materials, and control the fiber length at 2-5 cm, to improve the density and fermentation efficiency of mixed silage, and to meet the demand for long-term storage under a high temperature and high humidity climate.

Silage chopper solutions and technical advantages

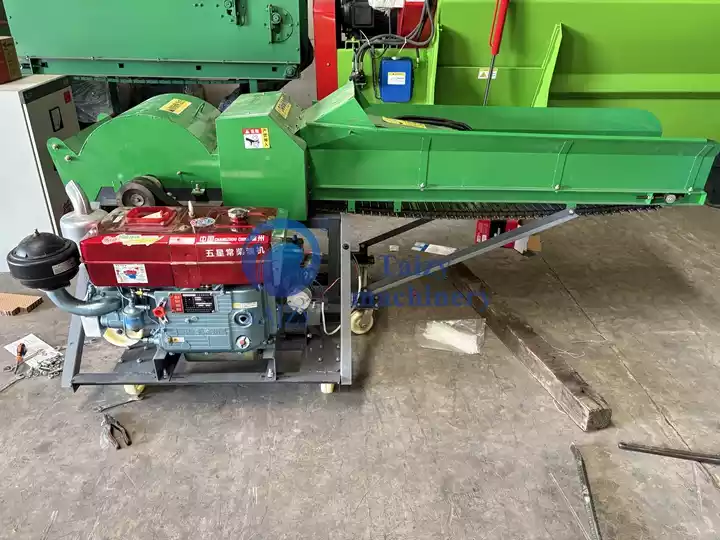

- The silage chopper machine delivered this time integrates the triple functions of cutting, crushing, and kneading.

- Equipped with high-strength alloy blades and a frequency conversion speed control system, it can handle high-fiber raw materials with hardness up to HRC55, and the hourly processing capacity reaches 8-10 tons, which is 15 times higher than the manual efficiency.

- The equipment supports the flexible processing of straw with water content of 30%-60%, avoiding the carbonization of fiber caused by high-temperature operation.

- For the tropical climate, the equipment adopts corrosion-resistant stainless steel shell and waterproof motor, and is equipped with overheating protection system to meet the demand for high-intensity operation in the rainy season.

- The machine and the customer’s existing baling and wrapping machine seamless integration, crushed raw materials through the automatic conveyor belt directly into the baling process, reducing intermediate losses.

After the equipment is put into use, it is expected that the comprehensive cost of feed processing will be reduced by 25%, the utilization rate of raw materials will be increased by 30%, and the improvement of silage quality is expected to increase the average daily weight gain of beef cattle by 18%.

If you want to know more about the machine in detail, please click 4-15t/h grass cutting machine / cutting wet grass / grass cutter. Feel free to contact us.