In the livestock farming industry, silage is crucial for ensuring a stable year-round supply of feed for cattle and sheep. However, the production cost per bale of corn silage has long remained high, with significant labor input, inadequate wrapping, and severe feed waste becoming major factors limiting profit growth on ranches.

Today, the new generation of baler wrapper machines is revolutionizing production through mechanization and automation upgrades. This transformation is significantly reducing costs, shifting silage production from a “high-cost investment” to a “high-efficiency return.”

Costs of traditional silage baling

Under the traditional model, the cost per silage bale primarily stems from the following aspects:

- High raw material loss: corn stalks, alfalfa, and other raw materials account for over 60% of total costs. Improper wrapping or uneven density can lead to mold growth and spoilage, directly causing feed waste.

- Low film utilization: traditional wrapping methods lack precise tension control, leading to significant film waste. Upgraded pre-stretch technology improves film efficiency, reducing wrapping costs by approximately 20%-30%.

- High labor input: manual baling is inefficient and typically requires multiple operators. A single automatic baling and wrapping machine can complete the entire process with one operator, reducing labor costs by over 50%.

- Limited production efficiency: traditional equipment has poor continuous operation capability and slow bale output, struggling to meet the demands of large-scale ranches.

How does a baler wrapper reduce costs?

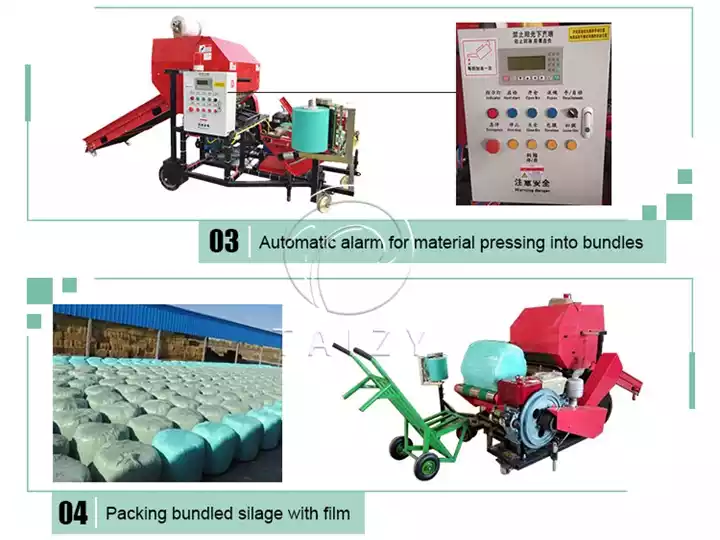

- The conveyor chain ensures stable feeding, producing tightly packed, uniform bales that enhance silage fermentation quality and minimize secondary losses.

- Automatically adjusts wrapping tension for tight, airtight coverage, effectively preventing mold growth and extending feed shelf life.

- Processes corn stalks, alfalfa, straw, and more—one machine for multiple uses, maximizing equipment utilization.

- Compact structural design adapts to diverse terrains, featuring low maintenance costs for cost-effective long-term operation.

Overall, mechanized processing reduces comprehensive costs per silage bale by 20%-40%, enabling many ranches to recoup investment within a single production season.

Conclusion

The benefits of upgrading silage forage baling and wrapping equipment extend beyond cost reduction, including:

- Enhanced silage quality with superior nutrient preservation

- Improved feed utilization and reduced waste

- Increased production efficiency with doubled daily output

- Greater assurance for large-scale development

Whether for family farms or large-scale operations, automated baling and wrapping technology has become essential equipment for boosting competitiveness. We welcome inquiries for more detailed information.