Full-Automatic Silage Baler Machine Forage Baling Equipment

Full-Automatic Silage Baler Machine Forage Baling Equipment

Forage baler | Hay baling machine

The round silage baler machine consists of two parts: bundling and film wrapping, is professional equipment that can wrap various stalks, grass, straw, etc.

Our factory has been focusing on the processing and export of silage machines for many years. We are currently able to produce three types of baling and wrapping machines, including the classic TZ-55-52 model, the TZ-70 model, and the newly launched 9YDB-60 model.

The characteristic of different types of silage balers is that the entire baling and wrapping process is automated. However, there are differences in the discharge port and the size of the finished bale. This article will introduce the characteristics and advantages of these three machines in detail.

And we have exported the automatic silage baling machine to Kenya, Pakistan, South Africa, Malaysia, etc. Also, we have a long-term cooperative relationship. What’s more, we also manufacture the grass cutting machine. Because the silage baler machine can produce the best effect for the silage that is filamentous. It is better to use the grass cutter before wrapping the silage.

Application of the corn silage baler machine

Silage baler machines have been widely used abroad as the main equipment for forage and straw harvesting. This silage baler machine is suitable for squeezing and bundling corn stalks, wheat straw, rice straw, pasture grass, and peanut seedlings, all kinds of silage, dry straws.

This corn silage baler machine can greatly reduce the storage area, improve transportation capacity, and reduce the possibility of fire. Therefore, it is indispensable and preferred equipment for animal husbandry and papermaking.

Type 1: Full-automatic TZ-55-52 baler machine

It is a full-automatic silage baler machine, with a 6.6 kW motor. 4500x1700x1500 mm is its size, silage baling machine has high speed, that is, 50-70 bundles/h. There is a 2-4 coated layer, and the bale density is 450 kg/m3. The length and diameter of the bale are 55cm and 52cm.

It bears a long storage time due to its round shape with film, which can be used for feeding animals. The raw material of hay and straw baler machines can be silage, fresh or dry straws of wheat, rice, soybean, corn, etc.

Full-automatic straw silage baler machine working video

This round silage baler machine is to preserve green and juicy fodder (fresh corn straw, pasture, etc.) under anaerobic conditions (by microbial fermentation). At present, silage has been widely used in animal husbandry all over the world. It is an important machine for feeding ruminant livestock (cows, cattle, sheep, deer, horses, donkeys, etc.)

Automatic silage baling machine parameter

| Round shape with film for long-term storage | TZ-55-52 |

| Motor | 5.5KW+1.1kw |

| Dimension | 4500x1700x1500mm |

| Operating speed | 50-70bundles/h |

| Bale density | 450kg/m3 |

| Coated layer | 2-4 layer |

| Coated efficiency | 8seconds/bale for 2 layers |

| Baling type | Round shape with film for long time storage |

| Raw material | Suitable for nearly all kinds of silage, straws of wheat, rice, soybean, corn, etc fresh or dry |

| Feature | Baling and coating automatically |

The rope and film are two important parts, and you should buy extra bags of them if ordering this baler machine. You shall cross the rope to the machine through the specific hole before the operation, which is very easy to do.

Technical parameters of the rope

| Model | Weight | Length | Package | Quantity |

| Model one | 5kg | 2500m | 6 roll/bag | 85bundles |

| Model two | 4kg | 2000m | 70bundles | |

| 5kg | 2500m |

The minimum order of rope is 50 bundles, and its service life is 2-3 years.

Technical parameters of the film

| Model | Weight | Length | Thickness | Package | The film quantity of 2-layer | The film quantity of 3-layer |

| Model one | 9.2kg | 1800m | 20u | 1roll/box | 80 bundles | 55bundles |

| 10.4kg | 1800m | 25u | ||||

| Model two | 25cm*1800m |

The minimum order of film is 50 bundles, and its service life is 2-3 years.

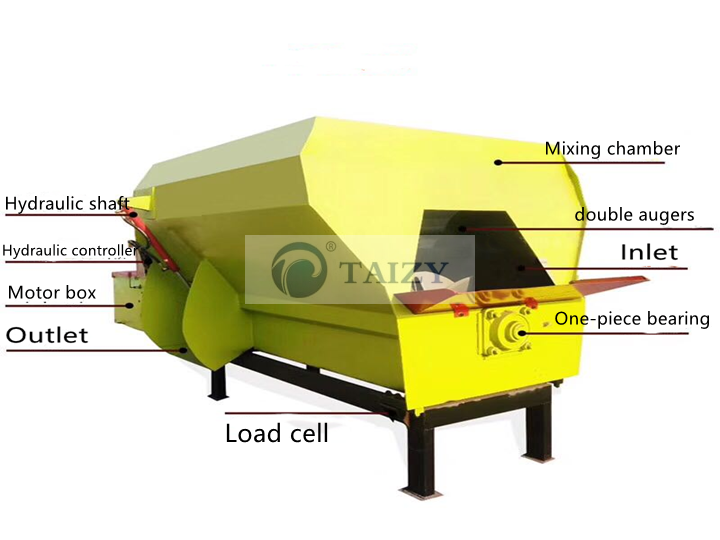

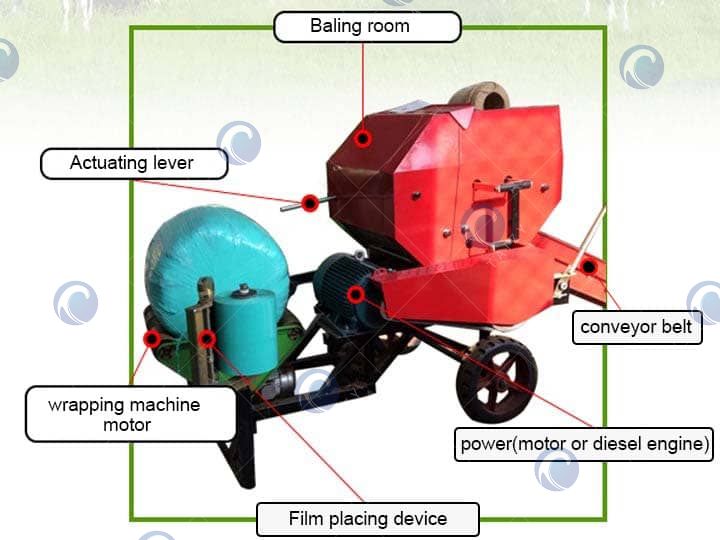

Main structure of round silage packing machine

- Baling part: The forage is fed into the working chamber of the baler quickly, uniformly, and evenly for compression. When the weight of each bundle reaches about 80 kg and the signal wheel rotates at a constant speed, the winding clutch handle is pulled and the rope can be used for baling. After baling, the rope is cut, and the user starts up the opening handle to make the bundles come out. In this way, the bundling process is completed.

- Wrapping part: The bales of the baling machine are placed on the two parallel belts of the wrapping machine, and the wrapping switch drives the bales by rotating the frame to rotate. The bales stretch the plastic film to wrap automatically. Then, users can set the number of coating layers(2 to 4 layers).

How to install a silage baler machine?

- First is the installation of the silage. The red chip of the silage film is facing up and then fixed on the film conveying frame. Then you should use a fixture to adjust its angle.

- The distance between silage films should be proper. If the distance is too wide, we should adjust the two screws under the conveyor.

- Second, place the rope to pass through the hole in the silage baler machine.

- Third, connect the wires. You should connect the three-phase electric wires to the inside of the control box. There are two-time adjusters including conveying rope and baling.

- Fourth, install the air pump. Connect the air pump motor to the power supply, connect the air pipe to the machine, and open the vent switch. The air pressure during the operation should be maintained between 0.6 and 0.8 Pa.

- Check all parts of the machine carefully before use and confirm that the machine is running in the right direction.

Type 2: TZ-70 Silage baling wrapping machine

This machine is the same as the 55-52 model in terms of working principle and structure. The difference is that the diameter of the finished round bale of this machine is 70cm, and it can only be tied with a plastic net rope. The output can reach 50-60 bales per hour, and each bale weighs 180-260kg. The machine is relatively large, so it is equipped with a 3 or 5m³ silo.

Corn silage baler wrapper parameters

| Model | 9YJD-70 |

| Power | 11kw+0.55kw+0.75kw+3kw+0.37kw |

| Bale size | Φ70*70cm |

| Bale weight | 150-200kg/bale |

| Capacity | 55-75bales/h |

| Air compressor volume | 0.36m³ |

| Feeding conveyor(W*L) | 700*2100mm |

| Filming cutting | Automatic |

| Wrapping efficiency | 6layers need 22s |

| Size | 4500*1900*2000mm |

| Weight | 1100kg |

Working video of TZ-70 silage baler machine

A successful case of straw baler wrapping machine

We delivered 2 sets of silage baler machines to Guatemala this week, this customer wanted to bale corn straw, so he also bought one straw cutter machine from us that can crush corn straws into small pieces, for the baler machine only can bale crushed straw.

Type 3: 9YDB-60 Silage bale wrapping machine

The packaging chamber of this machine adopts a herringbone belt design and has functions such as fully automatic packaging, film pulling, opening and closing of bins, and bag turning. It has extremely high production efficiency and can bundle 50-75 bags per hour. Each bag weighs 90-140kg and has a size of φ600*520mm.

Baler machine technical data

| Model | 9YDB-60 |

| Bale size(mm) | Φ600*520 |

| Bale weight(kg) | 90-140 |

| Capacity | 50-75 bundles/h |

| Rated speed(r/min) | 350 |

| Supporting power(kW) | 7.5kW-6 |

| Machine size(mm) | 3500*1450*1550 |

| Matching forage film (L*W*H) | 1800m*250mm*25mm |

Silage baler machine working site

What is the best partner for a stalk baler machine?

Please check the working video. Before baling the silage, we can process the stalk by using the chaff cutter machine. The processed stalk can enter the baler’s conveyor directly. It is good for saving the stalk’s nutrition. So, the chaff cutter is the best partner for a round silage baler. Customer can choose according to their needs.

FAQ of silage baler and wrapper machine

What is the raw material?

The raw material is nearly all kinds of silage, fresh or dry straws of wheat, rice, soybean, corn, etc.

What is the difference between the two silage baler machines?

The difference between them lies in whether the bundles can move to be baled with film automatically. As for the semi-automatic baler machine, people need to push the bundles to the baling part.

Can I adjust the size of the bundles?

No, it can not be adjusted.

How many layers are around the bundle?

2-4 layers. You can adjust according to your needs.

Use and maintenance of the baling machine

Use of the baler machine

Regular maintenance of the baling machine is very important to ensure the safety of the operator. For example, lack of maintenance (excessive wear, excessive accumulation of grass, lack of lubrication, etc.) will cause the bale phase to overheat and cause a fire.

- Before starting up, check whether all parts are firm and reliable, and add enough lubricating oil before starting up.

- Before starting the machine, the machine should be rotated manually for 3~5 weeks to confirm that there is no abnormality before starting the machine.

- Before starting the machine, pull the clutch handle to check the direction of rotation and whether it meets the requirements. It is strictly prohibited to turn on the machine in reverse.

- Before each work, run the machine empty for 2~3 minutes to confirm that the machine rotates smoothly and there is no other abnormality.

Maintenance of silage baler machine

- After the load test machine is 3~5 bundles, the machine should be shut down to check whether there are other abnormalities in the rotating parts and fixed parts: if there is no abnormal phenomenon, it can be put into production.

- Every half an hour of work, the small silt under the feeding roller of the machine should be removed to reduce the resistance caused by this: it also reduces the wear of the lower aluminum roller.

- Note: Cut off the power source before manually clearing any blockage.

- The machine should be maintained after the normal production of 2000 bundles. Turn it on again and still use it according to the previous 6 regulations. Maintenance and inspection of content.

Advantages of round bale wrappers

- Improved storage: wrapping with plastic film can help protect forage from moisture, air, and other environmental factors. This reduces spoilage and maintains the quality of the forage over a longer period.

- Reduced labor costs: silage baler machines can get the job done quickly. Wrapped bales are easier to handle and transport than loose forage. This can reduce the need for labor, saving time and money.

- Improves feed quality: wrapping feed in plastics helps to maintain the nutritional value of the forage. This is because it prevents the growth of harmful bacteria, molds, and other microorganisms that can reduce the quality of feed.

Taizy silage baler and wrapper machine

Taizy produces three different models of silage baler for sale.

There are two types of silage baler machines produced by Taizy. One is fully automatic and the other is semi-automatic. The semi-automatic version requires more labor and is cheaper. We will recommend the right type of machine according to the customer’s specific needs.

So far we have exported baling and wrapping machines to Kenya, Nigeria, the Philippines, Peru, Indonesia, Malaysia, Qatar, Guatemala(Corn silage baler machine sold to Guatemala), etc.

If you are interested, please feel free to contact us anywhere!