Our customer is from Alibaba. The customer’s needs were clear and he indicated on the RFQ that he needed a corn silage baler machine. Our sales manager saw it and contacted the customer directly. Then we added WhatsApp to communicate with the customer. After that, we understood that the customer was buying a maize silage machine for his company.

According to the customer’s needs, we provided him with a quote for a TZ-55-52 silage packing machine. The customer said he was satisfied with the machine, but he needed additional film, net, and yarn. So our sales manager update the quotation. The customer finally decided to buy it and we also confirmed with the customer the destination for shipping the machine.

Application scope of the corn silage baler machine

This corn silage baler machine is suitable for silage of pasture, wheat straw, rice straw, corn straw, alfalfa, sugar cane tail leaves, groundnut vines, reeds, bean seedlings, etc. The baled silage has a high commercial value and turns the waste of crops into treasure.

Also, the silage baler machine improves the utilization rate of resources and makes up for the shortage and low quality of forage sources for animal husbandry. It also reduces the cost of feeding, improves the production and quality of meat or milk, and makes the pasture industry commercialized.

How about the parameter of the silage baler machine?

| Model | TZ-55-52 |

| Power | 15hp diesel engine |

| Bale size | Φ550*520mm |

| Baling speed | 50-60 pcs/h, 5-6t/h |

| Machine size | 3520*1650*1650mm |

| Machine weight | 850kg |

| Bale weight | 65-100kg/bale |

| Bale density | 450-500kg/m³ |

Net’s detailed information

| The length of a roll of net | 50cm |

| Diameter | 22cm |

| Weight | 11.4kg |

| Packing | plastic film |

| Packing size | 50*22*22cm |

| A roll of the net is about 280 bundles |

Parameter of the packing film

| Weight | 10kg |

| Length | 1800m |

| Packing | 1 roll/carton |

| Packing size | 27*27*27cm |

| 1 roll can wrap 55 bundles |

Specification of the yarn

| Weight | 5kg |

| Packing | 6pcs/PP bag |

| Length Packing | 2500m |

| Bag Packing size | 62*45*27cm |

| 1 roll yarn can bind about 85 silage bales |

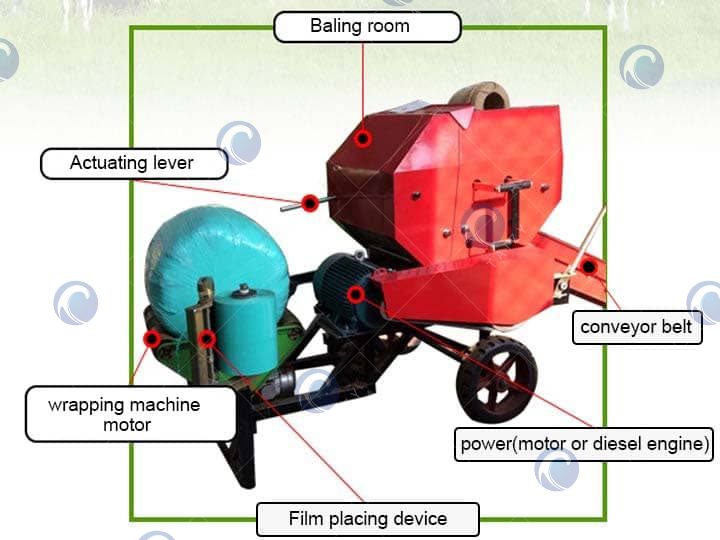

The composition of the automatic silage making machine

This automatic silage-making machine mainly includes baling room, conveyor belt, power(motor or diesel engine), film placing device, wrapping machine motor, actuating lever, etc. The TZ-55-52 bale wrapping machine can bale bales of 55cm in length and 52cm in diameter. The bale wrapping machine can bale silage with good quality, is easy to transport, and keep for a long time. It is the necessary equipment for baling feed-in farming plants.

What are the advantages of the corn silage baler machine?

1. The round silage baler machine is one of the special equipment for silage, micro-silage, and yellow silage wrapping. This machine can automatically wrap the fresh straw and fresh grass bales.

2. This maize silage machine can change two layers of wrapping, three layers of wrapping, four layers of wrapping, and six layers of wrapping after adjusting the counter.

3. Silage bales wrapped by this machine can be preserved for 1~2 years after natural anaerobic fermentation.

4. This silage baler can work with the chaff cutter.

5. Compared with similar products at home and abroad, this machine has the advantages of reliable and dense film wrapping, good stretching effect, flexible and convenient operation, and can save about 25% of the film.

Compared with the traditional silage, the film silage has the following characteristics

1. Good quality of stored feed. The good sealing of stretch film wrapped silage, improve the quality of the anaerobic fermentation environment of lactic acid bacteria. And improve the nutritional value of the feed, aromatic smell, high crude protein content, low crude fiber content, high digestibility, good palatability, high feeding rate, and the high utilization rate of livestock.

2. No waste mold loss, fluid loss, and feeding loss are greatly reduced. Traditional silage loss up to 20%-30%.

3. No pollution of the environment. Due to the good sealing performance, there is no liquid outflow phenomenon. Proper packaging, small volume, high density, ease of transport, and commercialization, to ensure a balanced supply. And year-round use of modern livestock silage for small, medium, and large dairy farms, beef cattle farms, goat farms, farmers, etc.

4. Long preservation period. Compaction sealing is good, and not affected by the season, sun, rainfall, and groundwater level. And can be stacked in the open air for more than 2-3 years.

Packing and shipping of the automatic silage making machine

After confirming all the machine details with the customer, the customer paid the deposit. We start to make the corn silage baler machine. Before shipping the machine we pack it carefully. Usually, we use wooden boxes for packing. This is good for moisture and avoiding bumps. Here are the packing and shipping pictures of the automatic silage-making machine.