Double and Triple Oil Cylinder Silage Hay Hydraulic Baling Machine

Double and Triple Oil Cylinder Silage Hay Hydraulic Baling Machine

Hydraulic silage baling machine | Hay baler

Features at a Glance

Hydraulic hay bale is a machine to compress, bale, and pack crushed corn straw, hay, and other grasses, bearing a compact structure, easy operation, steady and reliable transmission, and excellent flexibility.

Baling hay machines are widely applied to the ensilage and desiccation of silage or hay, greatly improving its cleanliness and saving storage space. Most importantly, grass baled by baler machine takes longer to feed animals and reduces storage and transportation costs.

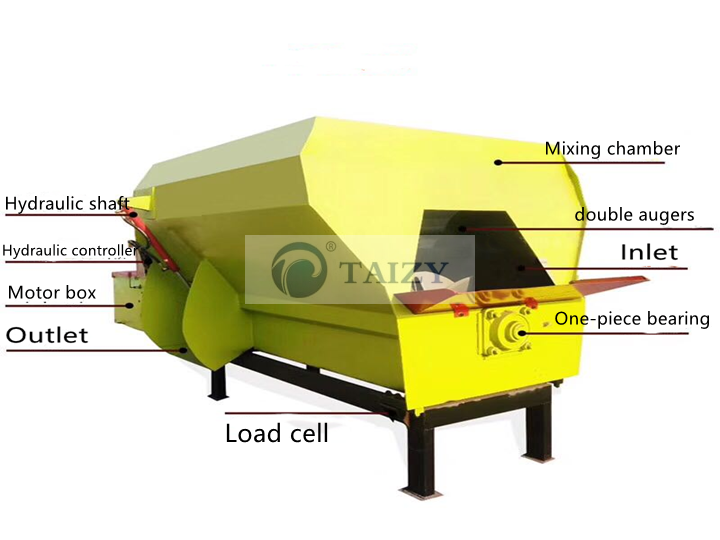

Type one: double oil cylinder hydraulic baler

This hydraulic hay bale machine can wrap up very crushed materials and can be preceded by a chaff cutter(4-15t/H Grass Cutting Machine / Cutting Wet Grass / Grass Cutter). This straw baler has two oil cylinders, which means the grass is pressed twice during operation, matching with a 15kw motor or 28HP diesel engine.

Technical parameter of hay bale machine

| Model | 9YK-70 (double oil cylinders) |

| Power | 15kw motor or 28HP diesel engine |

| Displacement of oil cylinder | 63-80L/min |

| Normal pressure of oil cylinder | 16Mpa |

| Bale size | 700*400*300mm |

| Bale Density | 300-400kg/h |

| Bundling efficiency | 1-2t/h |

| Weight | 1500kg |

| Dimension | 3400*2800*2700mm |

Working principle of hydraulic hay bale machine

- Add oil to the oil tank before working and the volume of oil should take up 2/3 of the whole tank.

- Crushed silage is placed into the machine from the upper inlet.

- The oil cylinder presses the silage horizontally when it enters the baling part.

- Then the other oil cylinder at the back of the silage outlet presses the silage again, then pushes them out, and you can put a bag on the discharge hole to collect the baled silage.

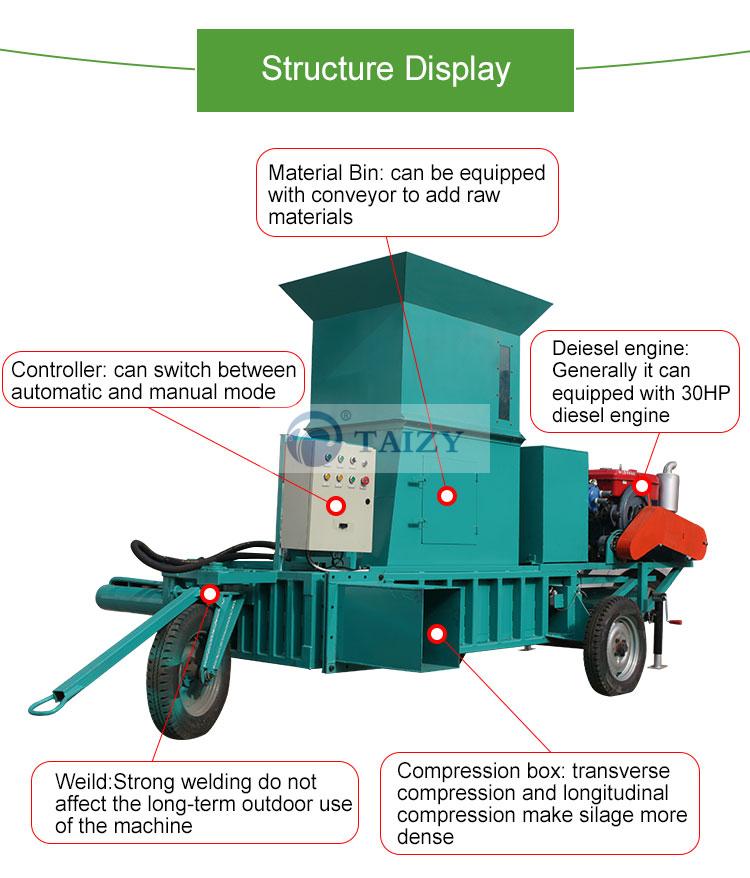

Type two: three oil cylinder hay bale machine

Technical parameter of hay bale machine

| Item | 9YK-130 (three oil cylinders) |

| Power | 22kw |

| Displacement of Oil Cylinder | 80L/min |

| Normal Pressure of Oil Cylinder | 18Mpa |

| Bale Size | 700*400*300 |

| Bundling Efficiency | 6-8t/h |

| Bale Density | 800-1100kg/m3 |

| Weight | 2600kg/h |

| Dimension | 4300*2800*2000mm |

| Speed of Bundling Piston | 4-8m/min |

How to install a hydraulic hay bale machine (for double oil cylinders)

Installation steps

First, take out 1 and 2 from inside of the machine.

- 1. hydraulic cylinder 2. pushing baffle

Insert the embolus(3) into the hole in the hydraulic cylinder (4).

- 3. embolus 4. fixed hole of baffle

Fix the fixed hole of the hydraulic cylinder(5) and the fixed hole of the pushing baffle(6) like the following.

- 5. Fixed hole of hydraulic cylinder 6. The fixed hole of the pushing baffle

Install hydraulic oil pipe, the short oil pipe (above) is mounted on the inner side, the longer oil pipe (below) is installed on the outer side.

- 7. hydraulic oil inlet 8. longer oil pipe

Advantage of hay bale machine (for two types)

- The hydraulic hay bale machine can improve the cleanness level of silage feed. The baled silage has a longer storage time, which is beneficial for animals to eat.

- Oil in the oil cylinder can be recycled again and again, saving cost. All processes go automatically which saves time and energy.

- The baled grass saves labor time, reduces labor intensity, and decreases occupation costs.

- The hydraulic hay bale machine has two different modes of power supply, such as a motor and a diesel engine.

- The processed materials maintain freshness and original taste, and it is green and clean that animals prefer to eat.

- Hay bale is suitable for a variety of animal husbandries, such as farms and pastures. Many farmers and distributors have already purchased it.

- The processed materials have the same volume and size, meeting the packaging standards, and they are convenient for transportation and storage.

- Automatic control cabinet, one-button start processing, and packaging, which is simple and convenient.

Hydraulic hay baler successful cases

We delivered 2 sets of double oil cylinders hydraulic hay bale machines to Nigeria and Mexico respectively, and the following are the delivery details. They are moving the machine to the container. One of the customers’ raw materials is bagasse.

FAQ of hydraulic silage baling machine

What is the difference between two hydraulic baling press machines?

The grass-backed by three oil cylinders machine has a longer storage time than baled by two oil cylinders one.

How much oil should be put in the oil cylinder before working?

2/3 of the oil cylinder.

Do I need to add oil to the cylinder constantly during operation?

No, the oil can be recycled again and again, and the whole process won’t waste much oil.

What can be the raw material?

Crushed silage, straw, hay, and other grasses.

Contact us at any time

If you are interested in our straw hydraulic hay bale machine or want to know more detailed information, feel free to contact us. Our professional team will provide detailed product information, answer your concerns, and ensure that you choose the most suitable equipment for your needs.