Last month, one of our nursery tray seeding machines was sent to Australia, along with a matching air compressor. The customer, who has been cultivating raspberries, purchased the machine to specialize in strawberry seed cultivation to diversify his business.

Learn more about this machine through Nursery seeding machine | Seeder machine | Vegetable seeder machine.

Details of nursery tray seeding machine

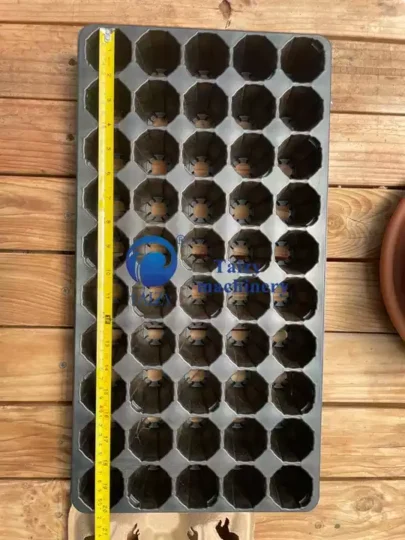

Through precise communication, we understood the customer’s specific needs for the hole trays, including key parameters such as size and center hole spacing.

Based on the precise sketches provided by the customer, the two companies worked together to design a nursery system that meets the needs of strawberry seeds that are extra small, including the No. 1 suction needle that is specially equipped for precise planting.

Nursery Machine

- Model: KMR-78

- Capacity: 200tray/hour

- Size: 1050*650*1150mm

- Weight: 68kg

- material: carbon steel

Air compressor

- Power: 3KW/ 4HP

- Voltage: 240v50hz

- Exhaust volume: 0.36m³/min

- Air tank: 110L

- Pressure: 0.8Mpa

- Weight: 80Kg

- Size: 1100*400*800mm

Nursery seedling machine transaction process

The design of this nursery tray seeding machine takes into account the special characteristics of strawberry cultivation, especially the tiny strawberry seeds, which require highly precise sowing techniques. The matching air compressor ensures the stability and reliability of the whole seedling nursery process.

Remarkably, thanks to our improved production technology, the factory was able to realize mass production. From order confirmation to shipment took just one week. After 25 days of sea transport, this state-of-the-art nursery system has arrived safely in Australia.