Silage baling na kufunika mashine vifaa vya baler

Silage baling na kufunika mashine vifaa vya baler

Baler ya kulisha silaji | Mashine ya kufunga baler ya nyasi

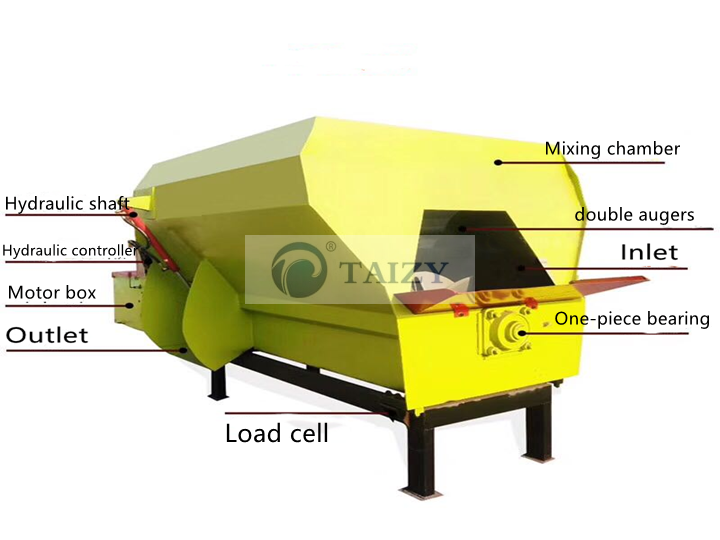

Vipengele kwa Mtazamo

Mashine ya kusawazisha na mashine ya kufunika ni aina ya kawaida ya vifaa vya utunzaji wa kulisha vinavyotumiwa na wakulima. Mashine ya kusawazisha na kufunika inaweza kufunika kila aina ya malisho na filamu ya plastiki, kamba, au wavu.

Vifaa vya kusawazisha nyasi ni kuhifadhi lishe ya kijani na yenye juisi (majani safi ya mahindi, malisho, nk) chini ya hali ya anaerobic (na Fermentation ya microbial). Ni mashine muhimu kwa kulisha mifugo ya ruminant (ng'ombe, ng'ombe, kondoo, kulungu, farasi, punda, nk)

Kulisha kwa baled huokoa nafasi ya kuhifadhi, inaboresha lishe ya malisho, na kuwezesha usafirishaji wa umbali mrefu kwa wakulima. Tuna aina mbili za mashine ya kusawazisha na mashine za kufunika, TZ-70-70 na TZ-55-52, na nakala hii ni juu ya TZ-55-52 baler. Kawaida, kabla ya kutumia baler tunaweza kuponda malisho na kikata makapi. Hii ni kwa sababu malisho ya kutibiwa ni rahisi kuota.

Iwapo ungependa kujua maelezo zaidi kuhusu mashine yetu ya kusaga silaji na mashine za kufunga, tafadhali bofya Mashine ya Silage Baler | Mashine ya Kutengeza Silaji ya Kiotomatiki Kamili.

Utangulizi mfupi wa Mashine ya Kufunga na Kufunga Mashine

Mashine ya TZ-55-52 ya moja kwa moja ya moja kwa moja ya moja kwa moja na gari 5.5kW na vipimo vyake ni 1600x1450x1060mm. Imewekwa na hali ya juu, kupata vifurushi 30-50 vya nyasi kwa saa, na kila bale ni 30-90kg. Mashine hii ya kusawazisha ina tabaka 2-4, na uzito wa mashine iliyofunikwa ni 135kg. Kuna kuzunguka pande zote na filamu ambayo inaweza kuhifadhiwa kwa muda mrefu.

Uboreshaji wa tairi kubwa ya kuvuta tairi

Baler yetu ya hivi karibuni ya Silaha 55-52 ya Silage na Wrapper imeimarishwa kutoka kwa mfano wa asili, sasa ikiwa na matairi makubwa ambayo yanawezesha harakati rahisi na harakati za haraka katika viwanja mbali mbali vya ardhi, na kuongeza kubadilika kwa utendaji.

Uboreshaji huu ni mzuri sana kwa Afrika na maeneo mengine yenye maeneo yenye changamoto na shamba zilizotawanyika, na kufanya mchakato wa kusawazisha na uhifadhi mzuri zaidi na wa watumiaji. Ikiwa ni kwa shamba kubwa au shamba ndogo, mfano huu unasimama kama chaguo bora la kuongeza tija ya kilimo.

Wigo wa Maombi ya Mashine ya Silage

Mashine hii ya kusawazisha nyasi na mashine ya kufunika inafaa kwa karibu kila aina ya silage, majani safi au kavu ya ngano, mchele, soya, mahindi, na kisha tunaweza kulisha silage iliyosafishwa kwa ng'ombe, kondoo, sungura, kulungu, farasi, Nguruwe, ngamia, nk.

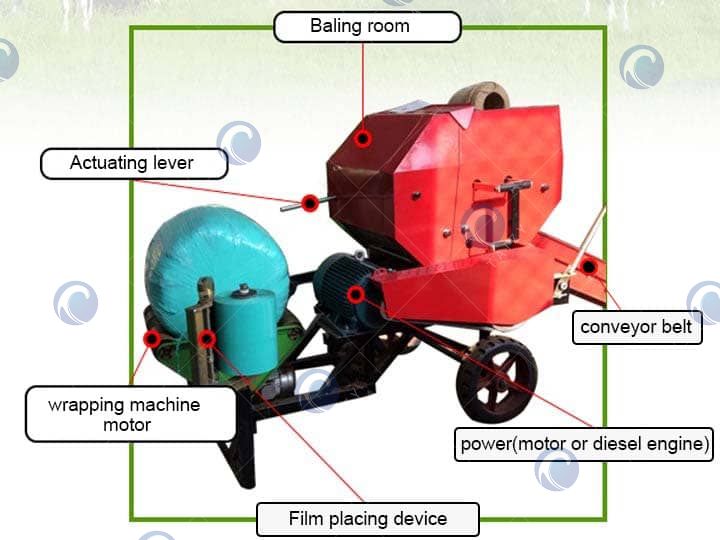

Mashine ya Mashine ya Hay Baler

- Kuvunja sehemu

Silage au malisho yametayarishwa na kugawa, kusagwa, na kuzidisha kuvunja sehemu ngumu za shina kwenye uso wa majani, na kuifanya iwe rahisi kwa mifugo kutumia sehemu za majani ambazo hazijakamilika moja kwa moja. - Sehemu ya kupiga

Uzalishaji hulishwa haraka na sawasawa ndani ya chumba cha kufanya kazi cha Bale kwa compression. Mara tu kila bale ina uzito wa takriban 80kg, gurudumu la ishara huzunguka kwa kasi thabiti, ikishirikisha kushughulikia kwa vilima ili kufunika bale na kamba. Baada ya kukata kamba, mtumiaji hufanya kazi ya ufunguzi ili kutolewa bale. - Sehemu ya kufunga

Bales zimewekwa kwenye mikanda miwili inayofanana ya mashine ya kufunika. Wakati swichi ya kufunika imeamilishwa, inazunguka sura ili kusonga bales. Bales kisha kunyoosha filamu ya plastiki kujifunga moja kwa moja. Watumiaji wanaweza pia kurekebisha idadi ya tabaka za mipako, kuchagua kati ya tabaka 2 hadi 4.

Kanuni ya Kufanya kazi ya Mashine ya Baler

- Opereta anatumia koleo kuweka majani kwenye ghuba.

- Baada ya dakika kadhaa, vifurushi vitakamilika chini ya nguvu ya kamba.

- Mtumiaji anasukuma vifurushi mbele na kisha kubofya kitufe, na vifurushi vitawekwa banda kiotomatiki.

Jinsi ya kufunga Mashine ya Baler ya Corn Silage?

Chip nyekundu ya filamu ya silage inakabiliwa na kisha imewekwa kwenye sura ya filamu inayowasilisha. Basi unapaswa kutumia muundo kurekebisha angle yake. Umbali kati ya filamu za silage unapaswa kuwa sawa. Ikiwa umbali ni pana sana, inaweza kubadilishwa na screw mbili chini ya conveyor.

Pili, weka kamba ili kupita kwenye shimo kwenye mashine ya kufungia na mashine ya kufunga.

Tatu, kuunganisha waya. Unapaswa kuunganisha waya za umeme za awamu tatu ndani ya sanduku la kudhibiti. Kuna marekebisho ya mara mbili ikiwa ni pamoja na kupeleka kamba na baling, ambayo inaweza kubadilishwa.

Nne, ufungaji wa pampu ya hewa. Unganisha injini ya pampu ya hewa kwenye usambazaji wa umeme. Unganisha bomba la hewa kwenye mashine, na ufungue swichi ya vent. Shinikizo la hewa wakati wa operesheni inapaswa kudumishwa kati ya 0.6 na 0.8Pa.

Angalia sehemu zote za mashine ya kusawazisha na mashine ya kufunika kwa uangalifu kabla ya matumizi na uthibitishe kuwa mashine hiyo inaendesha kwa mwelekeo sahihi.

Param ya kiufundi ya mashine ya kusawazisha na kufunika

| Mfano | TZ-55-52 |

| Injini | 5.5KW |

| Dimension | 1600x1450x1060mm |

| Uzito | 380kg |

| Kasi ya uendeshaji | 30-50 vifurushi/saa |

| Uzito wa bale | 30-90kg |

| Safu iliyofunikwa | 2-4 safu |

| Ufanisi uliofunikwa | 12seconds/bale 2 tabaka… |

| Uzito wa mashine iliyofunikwa | 135kg |

| Aina ya baling | Sura ya pande zote na filamu kwa uhifadhi wa muda mrefu |

| Malighafi | Inafaa kwa karibu kila aina ya silage, majani ya ngano, mchele, soya, mahindi, nk safi au kavu |

Mashine ya Kupakia Silaji Inauzwa hadi Bangladesh

Wateja wetu kimsingi ni kutoka Bangladesh, na wanatufikia kupitia kituo chetu cha YouTube. Mteja anatarajia kununua mashine ya kusawazisha na mashine ya kufunika kwa matumizi ya kibinafsi.

Wakati wa majadiliano, wasimamizi wetu wa mauzo hukusanya habari kuhusu bajeti ya mteja. Kama matokeo, meneja wa mauzo alipendekeza mashine ndogo ya kufunga Silage Baler TZ-55-52.

Wateja wanaamini mashine hii inafaa mahitaji yao vizuri. Kwa kuongeza, mteja alionyesha hamu ya kupakia malisho kwa kutumia nyavu na kamba. Mashine hii ni ya kutosha kutoshea chaguzi zote mbili, inashughulikia mahitaji ya mteja.

Maswali Yanayoulizwa Mara kwa Mara

Nguvu ya mashine ni nini?

Nguvu inaweza kuwa injini ya dizeli, injini ya petroli, au motor ya umeme. Aina tofauti za mashine zina mahitaji tofauti ya nguvu.

Madhumuni ya mashine ya kufunga baler ni nini?

Silage kavu au mvua, magugu, majani.

Mlisho uliopakiwa unaweza kuhifadhiwa kwa muda gani?

Miaka 2-3.

Je, mashine hutumia compressor ya hewa?

Mahitaji ya kiotomatiki kikamilifu, nusu-otomatiki hauitaji compressor ya hewa.