Venta de mezclador de pienso horizontal TMR | Mezclador de forraje | mezclador de puré

Venta de mezclador de pienso horizontal TMR | Mezclador de forraje | mezclador de puré

Silage feed mixer/Feed mixing machine

A horizontal feed mixer is a kind of feed processing equipment that integrates crushing, stirring, and mixing. It is mostly used in animal breeding farms, such as cattle farms and sheep farms. Thus this machine can fully mix coarse materials, concentrated materials, minerals, vitamins, other additives, etc.

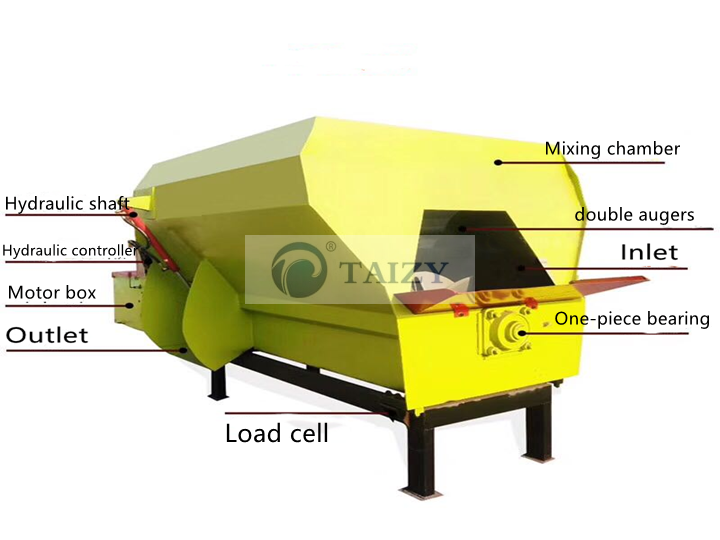

Estructura del mezclador de pienso TMR

The feed mixer contains several parts. You can get more information from the below picture.

1. Sistema interno

The internal system of the horizontal feed mixer is mainly composed of three augers, one is the main auger, and the other upper two are auxiliary augers.

Después de cortar el tallo de maíz usando un machi cosechando tallos de maízne, you can put the corn stalk into the horizontal feed mixer. During the mixing and cutting, the materials are simultaneously rotated and stirred from each position at both ends of the box to the middle of the mixer. Then the blade cuts and stirs the various fibrous forages and straws that pass through. To achieve the effect of pulverizing and mixing the total mixed ration feeding.

2. Sistema de descarga

Discharge gate control consists of a hydraulic cylinder, fixed support, linkage support, and a sliding discharge baffle. The discharging sliding baffle is installed on the reciprocating shaft of the hydraulic oil cylinder. Which can open the discharging or close the stopper. The outlet can be located on the left or right according to the user’s requirements.

3. Sistema de adición de pienso

The machine adopts an advanced grass-feeding mechanism and a unique grass-feeding roller device. It owns automatic feeding, smooth grass-feeding, and high production efficiency.

4. Sistema de pesaje y medición

It is composed of four bridge-type load-bearing sensors and a load-bearing display controller. All system uses a 220V power source to send signals to the weighing display through a four-directional bridge weighing sensor. It aims to display gross weight, net weight, peak value, and net weight. The weighing and measuring system also has an overload alarm function.

Vídeo de trabajo

Parámetro del mezclador de pienso

Tenemos tres tipos de mezcladores de alimento; puede obtener información detallada en la siguiente hoja.

| Modelo | / | TMR-5 | TMR-9 | TMR-12 |

| Dimensión | milímetros | 3930*1850*2260 | 4820*2130*2480 | 5.6*2.4*2.5 |

| Peso | kg | 1600 | 3300 | 4500 |

| Velocidad de rotación del sinfín | R/min | 23.5 | 23.5 | 23.5 |

| El volumen de la cámara de mezcla. | metro cúbico | 5 | 9 | 12 |

| Tipo de estructura | / | fijado | fijado | móvil |

| Rango de potencia de apoyo | kilovatios | 11—15 | 22—30 | 50-75 |

| Forma de poder de apoyo | / | Motor eléctrico | Motor eléctrico | Motor eléctrico |

Características del mezclador de forraje:

1. The cutting blade of this product is made of high-quality high-alloy steel. And the product design is reasonable.

2. Este producto tiene una estructura simple, por lo que es fácil de operar.

3. The efficiency of the product is extremely high, the cutting speed and stirring speed are fast enough. Thus the machine can reduce the workload of people and reduce the investment of manpower and financial resources.

4. Besides, a forraje mixer is equipped with an automatic feeding port, so the amount of feeding is even. So the production efficiency is extremely high.

5. Además, nuestro mezclador de alimento se puede personalizar según las necesidades del cliente.

Ventajas del mezclador de alimentación horizontal:

1. We can design a unique outlet according to the feed’s trajectory, it aims to achieve fast and uniform feeding efficiency.

2. El pienso se mezcla con alta uniformidad y aporte energético equilibrado. Por lo que es propicio para el crecimiento de los animales.

3. It has a simple structure, few wearing parts, and low maintenance cost.

4. Because the hydraulic transmission and mechanical transmission are of high reliability, they need short maintenance time.

5. The mixing chamber has less abrasion with a long service life.

6. Se corta el pasto al procesar el alimento, lo que no dañará la fibra gruesa.

7. This machine can process all kinds of roughages, and then directly add dozens of forages.

Máquina cortadora de césped para alimentación animal | cortador de paja | cortadora de pasto con gran capacidad

Producto caliente

Secador de grano de maíz, trigo, mijo, sorgo, a la venta

El secador de granos es un equipo especializado para secar…

Máquina extractora cortadora de cáñamo de yute Kenaf/descorticadora Kenaf

Breve introducción del decorticador de cáñamo Nuestro cortador de cáñamo...

Deshidratador de estiércol de pollo, vaca, cerdo y caballo | deshidratador de estiércol

El deshidratador de estiércol de ganado también se llama estiércol de aves...

rompe mazorcas de cacao | partidor de mazorcas de cacao | abridor de mazorcas de cacao

The cocoa pod breaker just need one person…

Pulverizador de mochila / mejores drones / pulverizador de mochila individual

Introducción del rociador de mochila: el rociador de mochila tiene un…

Máquina automática para plantar semillas de trigo, sembradora de trigo de 6 hileras

La sembradora de trigo es adecuada para funcionamiento directo...

Trilladora de maíz | Trilladora de maíz | desgranadora de maíz 5TYM-650

Este es un nuevo tipo de trilladora de maíz.…

Se venden dos modelos de cosechadora de patatas.

La cosechadora de patatas se utiliza ampliamente en campos grandes...

Máquina sembradora para viveros | Máquina sembradora | Máquina sembradora de hortalizas

Una sembradora de vivero es un dispositivo que...

Los comentarios están cerrados.