Compared with the traditional grain drying machine, a growing number of people prefer to purchase low temperatures and mixed flow bean drying machine(also can be used for other crops). What is the advantage of it? I will introduce in the six aspects.

Wide adaptation

The bean drying machine adopts low temperature, mixed flow, frequency conversion and other technologies. It is suitable for drying rice, wheat, corn, sorghum, soybeans, sunflower seeds, millet and rapeseed etc. Relatively speaking, the drying range of the mesh type cross-flow grain dryer machine is rather limited. Due to the restrictions of holes, it cannot dry grains with smaller holes such as rapeseed and millet. What’s more, the high-temperature grain dryer machine can only dry corn.

The power of bean drying machine is low

The total power is 7.6KW, and you do not need to buy a transformer. It is easy to install.

Fast precipitation and low bursting rate

The mixed-flow grain dryer machine optimizes the design of the cross-section size and the length of the corner, which changes the running direction of the grain. Meanwhile, it makes the grain fall with an S-shape in a 2.7-meter high drying layer to enable the uniform drying. In addition, extending the downward distance of the grain is more than 5.5 meters, and the grain is heated for a longer time at a low temperature. Such design is conducive to the drying of the grain surface.

Low heat consumption

It uses a low temperature and constant temperature without secondary pollution. The moisture in the bean drying machine is the same on the inside and the outside, and they will not be mildew. Therefore, you can store it for a long time.

The service of bean drying machine is long

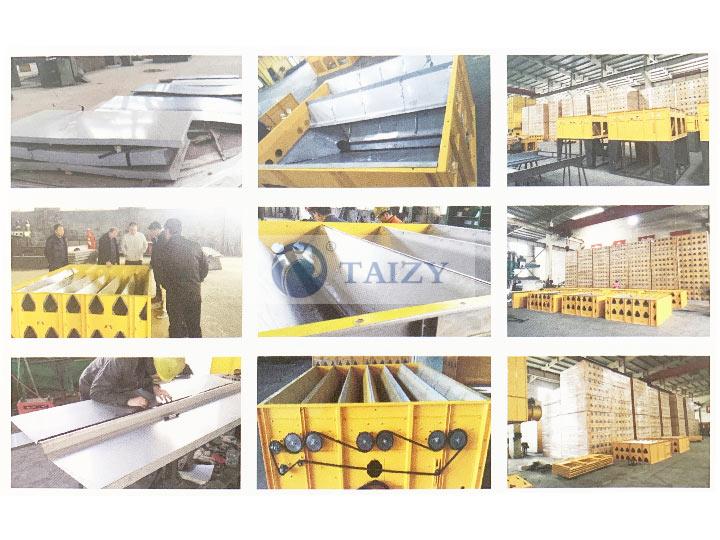

The main components of the bean dryer machine are thickened plates and stainless steel runners. The stainless steel is wear-resistant and smooth, and the grain flows smoothly. Thus, the grain will not be blocked. The surface of bean drying machine adopts an electrostatic spray paint process. However, the other grain dryer use of black iron plate and general spray painting process, which is are susceptible to rust, shortening the service life of the machine.

Low drying costs

The old type bean drying machine is often clogged with grain bran, causing poor ventilation and uneven drying. Even worse, it prolongs the drying time and the users need to afford the high drying costs with poor grain quality.

Our mixed-flow grain dryer adopts angled air intake, which has smooth ventilation and uniform drying. It is easy to clean. Importantly, the drying efficiency is 70% -80% higher than that of the mesh type cross-flow grain drying machine. Meanwhile, the drying cost is approximately doubled.