The visiting client from Turkey specializes in large-scale vegetable cultivation and project operations, primarily growing tomatoes, peppers, eggplants, and Panicum (Panicum grass). As their cultivation area expands, the client seeks to enhance seedling consistency and transplanting efficiency through mechanization, while identifying stable, mature nursery seedling transplanter machines for future overseas projects.

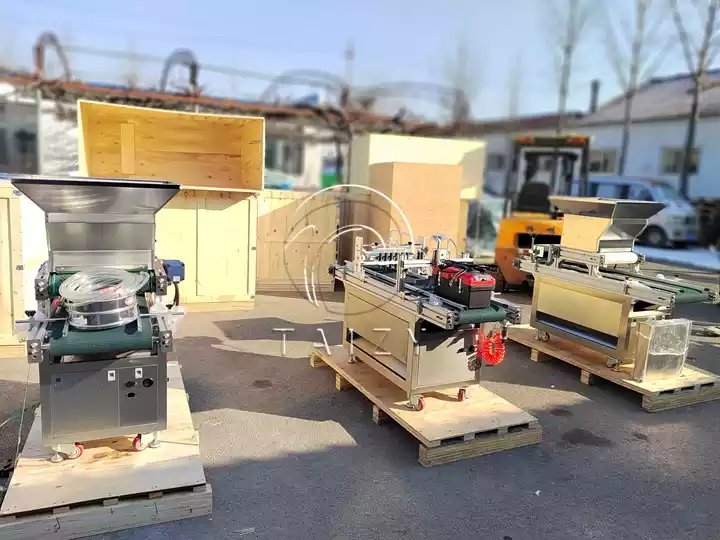

Nursery seedling transplanter machines factory tour

During the factory tour, the client focused on inspecting and conducting on-site trials of the fully automatic KMR80-2 seedling machine. This model has been upgraded to accommodate seed trays up to 350mm wide, better aligning with their multi-crop seedling production plans.

Rice seeds, whose particle size is similar to Panicum seeds, were used for testing. The trial demonstrated stable performance, with the client acknowledging the machine’s uniform seeding and consistent seedling emergence.

Equipment selection and purchase plan confirmation

Following multiple rounds of on-site discussions and testing, the customer finalized the purchase plan:

- 1 KMR80-2 fully automatic seedling machine for centralized standardized seedling production of various vegetables and forage crops.

- 2 six-row towed transplanter machines to complement the seedling machine, enabling seamless transition from seedling production to field transplanting.

This integrated solution meets the client’s practical requirements for efficiency, stability, and operational continuity.

This batch of seedling machines and transplanters will be shipped collectively to Iraq for local vegetable and forage cultivation projects. The client stated that this collaboration lays the foundation for establishing a complete seedling and transplanting machinery system. We’ll develop further equipment expansion plansbased on project progress.