Plug seedling machine | Nursery seedling machine

Plug seedling machine | Nursery seedling machine

Nursery seeder / Nursery tray seeding machine

Features at a Glance

The plug seedling machine is a special machine for cultivating seedlings of fruit and vegetable forests. The use of nursery machines can increase the germination rate and survival rate of seedlings. In addition, it can achieve large-scale seedlings, which greatly improves the efficiency of artificial seedlings.

People widely use it in the seedling industry of fruits, vegetables, flowers, and so on. It meets the needs of large and medium-sized seedling production enterprises, agricultural production cooperatives, private farms, and vegetable and flower production bases.

As a producer of agricultural machinery, we have vegetable transplanters and rice transplanters, in addition to the production of seedling machines. He helps people to plant more efficiently and conveniently.

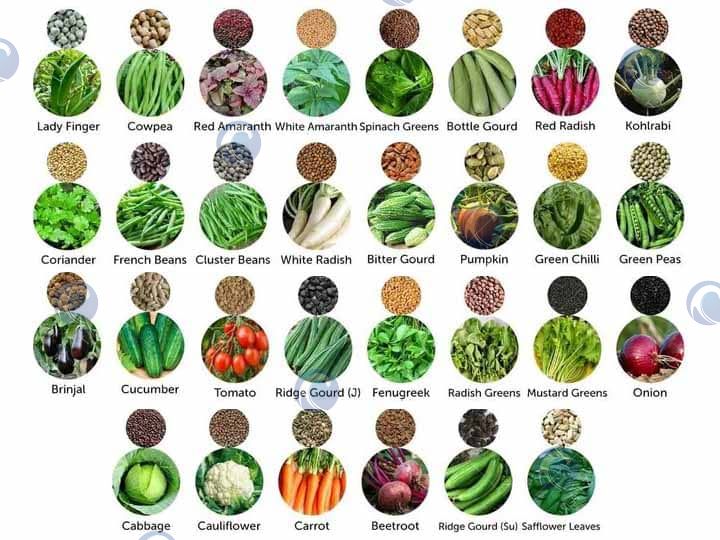

Application of the plug seedling machine

The plug seedling machine can sow various vegetable and flower seeds. For example, carrots, beets, reddish, kale, broccoli, turnip, mustard, spinach, arugula, amaranth, scallions, celery, cilantro, Bok choi, Tomato, lettuce, Chinese cabbage, cabbage, sweet corn, pumpkin, hemp seed, okra, cucumber, etc.

Working principle of the nursery seedling machine

The plug seedling machine of this series needs an air compressor during use. The precision seeding operation of seeds is realized by vacuum suction and positive pressure drop. The precision planter uses a vacuum device to generate a vacuum, and the negative pressure air absorbs the seeds from the seedbox.

When the sensor detects the plug, the metering device aligns with each hole. At this time, the negative pressure switches to a lower positive pressure, and the positive pressure is used to sow the seeds to a predetermined position in the plug tray to achieve precise seeding of one hole and one seed.

Different models of vegetable nursery seedling machine

Type 78 manual seedling machine

This model manual seedling machine is a semi-automatic tray seeder. The use of this seedling machine is required to manually put the plugs and take the plugs after sowing. The function of this model is mainly punching and sowing. Therefore this machine is small, lightweight, and less expensive.

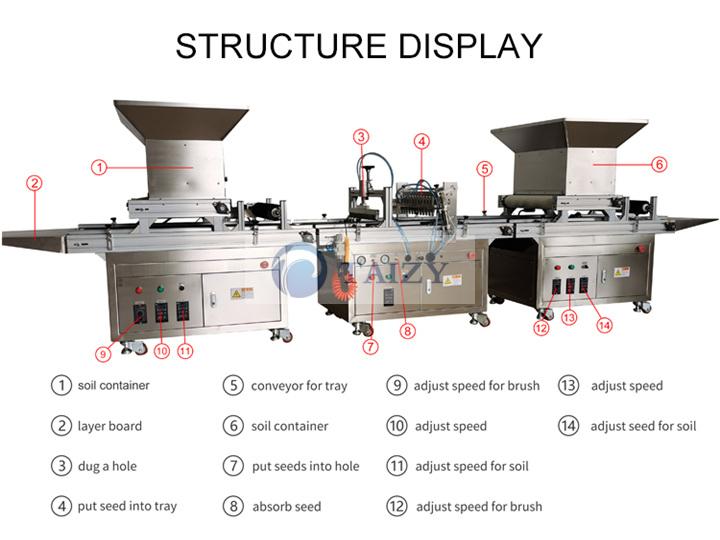

Structure of the vegetable nursery seedling machine

This 78-vegetable nursery seedling machine mainly has digging, planting, tray worktable, frame, etc. This tomato nursery seeding machine is convenient for you to move everywhere.

Work video of nursery seedling machine

Advantages of the manual tray seeder machine

This machine is small in size, light in weight, flexible in operation, simple in structure, and precise in seeding, cavitation, and seeding completed at one time. The working process is integrated and automatic pressing holes and seeding.

- According to different seeds and sowing requirements, you can configure the corresponding seed suction nozzle. The applicable seed size range is 0.3-12mm, and it is suitable for regular pepper, tomato, grass, and flower seeds.

- Automatically press the seeding hole with uniform depth. Sowing the seeds completely reaches one hole and one seed, without any damage to the seeds.

- This machine is easy to operate, which greatly reduces the labor intensity of the staff, and the workers only need to do simple tapping and placing actions.

Parameter of nursery seedling machine

| Dimensions (mm) | 1050*650*1150 |

| Applicable seed size (mm) | 0.3-12 |

| Seeding speed | 200-260 trays/h |

| Sowing accuracy | 98% (pelleted seeds) |

Type 80 automatic seeding machine

This automatic seeding machine is our fully automatic seedling machine, which can automatically mulch, punch holes, sow seeds, mulch again, and so on. It is also possible to add the function of watering. The machine has the same function as the 78-2 model. But the difference is that the machine has two parts, while the 78-2 model has three parts.

Work video of 80 automatic nursery tray seeding machine

Advantage of the automatic vegetable seeder

Based on the 78 manual models, it adds a computer control system and adopts a one-button one-button operating system. And the workflow is paving-pressing cave-sowing-covering soil. In addition, you can increase the sprinkling process if you need it.

It is a plug seedling machine that can complete the plug substrate filling, suppression, plug seeding, soil covering, and other processes at one time. It can be completed at one time. So it has high production efficiency.

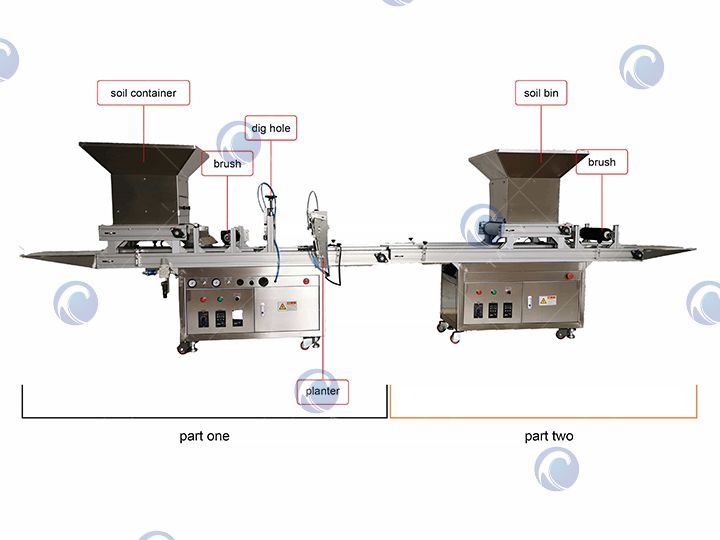

Components of the automatic nursery seed sowing machine

This 80 automatic nursery seed sowing machine has two parts. One part includes the soil bin, brushing, digging, and sowing. Another part has a second soil covering and brushing. Also, you can choose the watering at the end of the machine.

Technical information about the nursery sowing machine

| Dimensions (mm) | 4200*600*1260 |

| Maximum size of the plug tray (mm) | Width 300 |

| Applicable seed size (mm) | 0.3-12 |

| Seeding speed | 300-400 trays/h |

| Seeding accuracy | over 97% (pelleted seeds) |

Type 78-2 latest vegetable seedling machine

This 78-2 latest vegetable seedling machine has three parts, which facilitate the splitting and matching of the machine.

Structure of the nursery planting machine

What advantages does the nursery planting machine have?

Compared with 80 models, the planting speed is faster and smarter. Its degree of automation is the highest among existing planters. Take a video with a camera, then put it into a computer for processing and give an evaluation mode.

In this way, the planting position and quantity are automatically determined. In this way, it can not only complete the precision seeding process but also test the performance of the seeder. Therefore, it realizes the process of integrating production and inspection.

Detailed information on the plug seedling machine

| Dimensions (mm) | 5600*800*1260 |

| Maximum size of the plug tray (mm) | Width 540 |

| Applicable seed size (mm) | 0.3-12 |

| Seeding speed | 550-600 trays/h |

Advantages of using a plug seedling machine to grow seedling

1. The plug seedling technology has the advantages of saving labor, saving energy, facilitating large-scale management, and protecting and improving the ecological environment of agriculture. So, it is widely used in vegetable and flower production.

2. The main substrate used for plug seedling cultivation is peat soil, vermiculite, perlite, and other light substrates. These substrates have light-specific gravity, good air permeability and water retention, moderate pH, and low virus pollution.

The substrate does not adhere to the surface of the plug and is easy to come out of the tray. And does not stick to the surface of mechanical parts, which is convenient for mechanical operation.

3. Plug seedlings have a high germination rate and strong seedling vitality. Which significantly saves seeds.

4. The density of plug seedlings is several times higher than that of traditional seedlings. As a result, the fixed investment cost of the greenhouse is amortized per seedling. And the greenhouse operating expenses are greatly reduced.

5. Plug seedlings can achieve mechanized seeding. The use of a seeder assembly line can make the filling amount, seeding depth, compaction degree, and covering the depth of each hole of the plug the same. The emergence date and seedling size are uniform, which is beneficial to the commercialization of seedlings.

6. We can easily disinfect the entire production line of plug seedlings.

The principles that should be followed when choosing a seedling machine

When using plug seedling technology, how does choosing a plug seedling machine relate to the cost of seedlings and the quality of seedlings? Consider from the perspective of ecological and environmental protection. It does not contain live pathogens and larvae. And do not contain or try to avoid containing harmful substances.

To prevent environmental pollution and the food chain after they enter the growing field with the seedlings. To achieve this, it should ferment quickly with a starter, to achieve the purpose of sterilizing, killing viruses, and removing larvae.

1. The plug seedling planter must have a function similar to that of the soil. So from the perspective of nutrient composition standards and the growth environment, the cultivation substrate is more beneficial to plant growth than the soil. But it still needs to have other functions for the soil. Such as facilitating the coiling of the rhizomes (for lumping) and good water retention.

2. The plug seedling machine is equipped with organic and inorganic compound cultivation substrates. When configuring the plug seedling planter, pay attention to the scientific and standardized combination of organic. Adjust the air exchange, moisture, and health status of the plug seedling planter as soon as possible. And select and apply locally abundant, high-quality, and low-cost light cultivation substrates.

78-2 plug seedling machine shipped to USA

Our customer from the USA bought a 78-2 latest automatic vegetable seedling machine from us. The customer read our website and wanted to know more about our seedling machine. And based on the customer’s budget and desired output.

We recommended the 78-2 seedling machine to the customer. In the process of communication, we provided the customer with detailed parameters of the machine. The customer decided to buy a fully automatic seedling machine after understanding. Here is the packing and shipping picture of the machine.