Automatic Rice Nursery Seedling Machine Paddy Seed Sowing Equipment

Automatic Rice Nursery Seedling Machine Paddy Seed Sowing Equipment

Rice paddy nursery sowing machine | Rice seedling tray machine

The fully automatic rice nursery seedling machine integrates automatic soil spreading, seed sowing, sprinkling irrigation, earth-covering soil, etc. It can complete all the operation procedures of seedling sowing at one time. The use of this rice seedling sower greatly improves the precision sowing of small batches. It saves 20% on empty seeding rate than manual sowing.

At the same time, the machine has a good seedling effect, increasing production and saving costs. The disc cultivation bud planting line has the characteristics of slim, neat, and strong. The machine can use both plastic hard disks and floppy disks, and its efficiency is more than 900 disks per hour.

The spiral seeder meter meets the needs of precision seeding. It can realize the adjustable number of seeds and improve the uniformity. This rice seeder uses the key technical fields of the transplanting seedling industry to improve the automatic technology.

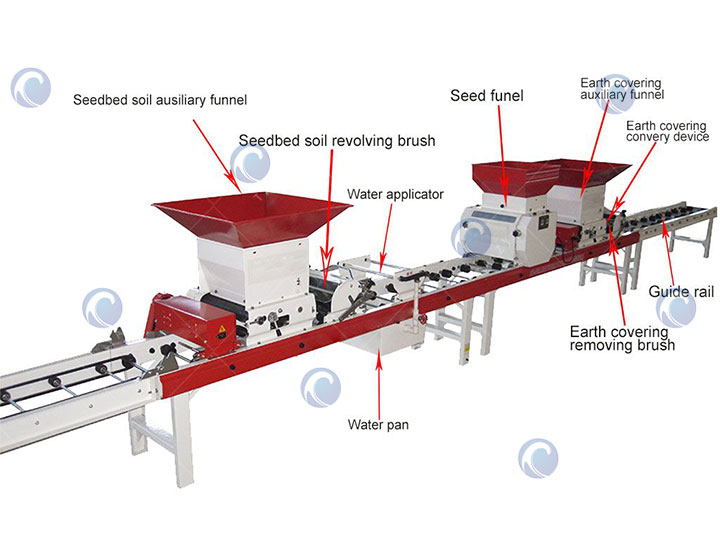

Structure of the rice seedling machine

The whole rice seedling raising machine can include a hanging plug seedling tray device, seedling plate covering device, seedbed soil revolving brush, spray setting, seed funnel, earth covering auxiliary funnel, earth covering removing brush, plates collecting machine, etc.

Technical parameters of rice nursery sowing machine

| Model | TZY-280A |

| Size | 6830*460*1020mm |

| Weight | 190kg |

| Power | 240W for deliver 120W for seeding |

| Seedbed soil auxiliary funnel | 45L |

| Seed funnel | 30L |

| Hybrid rice sowing quantity | 95-304.5g/tray |

| Capacity | 969-1017tray/hour |

| Thickness of subsoil | 18-25mm |

| Thickness of surface soil | 3-9mm |

Tips and attention when using a rice seeder machine

Tips

- Seedbed soil: choose vegetable garden soil, matured dry soil, or paddy soil for seedbed soil. Crush and sieve the soil. Then add biological bacterial fertilizer or rice special fertilizer.

- Rice seed: choose high-quality, high-yield, and stress-resistant varieties that are suitable for local planting as seedlings. Before seedling, sun the seed for 1 day and then soaked with the medicament for 72 hours to disinfect the seeds to kill the germs on the seeds.

- Seedbed preparation: pay attention to choosing seedling fields that are convenient for irrigation, drainage, and seedling transportation, and easy to manage. Of course, you can also choose to use the seedbed frame, which has a water spray system, and it is more convenient.

- Pay attention to the amount of seeding: generally, one seedling tray uses one paper cup of seed for seeding. The seeding is required to be accurate, uniform, not heavy, and not leaking. The automatic seedling raising machine can realize accurate seeding.

Attention

- When covering the soil, pay attention to the thickness of the covering soil, which is generally about 0.3 cm-0.5 cm, and it is better not to see the rice seeds.

- Pay attention to heat preservation and moisturizing during the seedling emergence period. Generally, we should control the temperature at 30°C. And when it exceeds 35°C, ventilation, and cooling should be performed. And we should keep the humidity above 80%, and drain water in time in case of heavy rain to avoid water accumulation in the seedbed.

- Fertilizer and water management. Pay attention to wet first and then dry. Before the seedlings have only three leaves, the soil or seedbed soil is moist. Control water before transplanting to promote the healthy roots of the seedlings. Apply fertilizer in time according to the seedling situation. When fertilizing, we should pour with water to avoid the direct application of dry fertilizer.

- Prevention is the first and combines prevention and control. At the same time, pull out the bad seedlings and weeds frequently to ensure purity.

2BZP-800 economic model rice nursery seedling machine

In the case of traditional rice nursery equipment, which is generally characterized by high price and complicated operation, the 2BZP-800 rice nursery seedling machine provides a cost-effective and practical solution for small and medium-sized farmers with the core of “light investment and high return”. The following are the core advantages.

- Designed for small and medium-sized farmers, the price is only 60%-70% of similar products. The sowing accuracy is stable at ±3% of the industry standard, with the groove roller seeder, to ensure that the amount of seed per tray is precisely controlled at 50-150g (adjustable).

- The whole machine measures only 3450×500×1010mm and weighs 124kg, easily adapting to the narrow space such as greenhouses and fields.

- Equipped with 35L large-capacity soil spreader and mulch box, the single loading can work continuously for more than 200 trays, which reduces time-consuming repeated refilling.

- Integrating the whole process of “soil spreading – watering – seeding – mulching”, the single machine completes the work of the traditional 4 sets of equipment.

- Soil spreading and mulching both adopt wheel and belt structure, with 0.025-0.125m/s adjustable conveyor belt, it can handle 500 trays in 30 minutes, and the efficiency is increased by more than 50%.

- The total power of the whole machine is only 260W (the traditional model is more than 500W), and the three motors of soil spreading, seeding and mulching are driven independently, and the power consumption is less than 1 yuan per day.

- Modular design of key components, seeding box, conveyor belt and other wear parts to support the rapid dismantling and replacement, without the need for professional maintenance personnel.

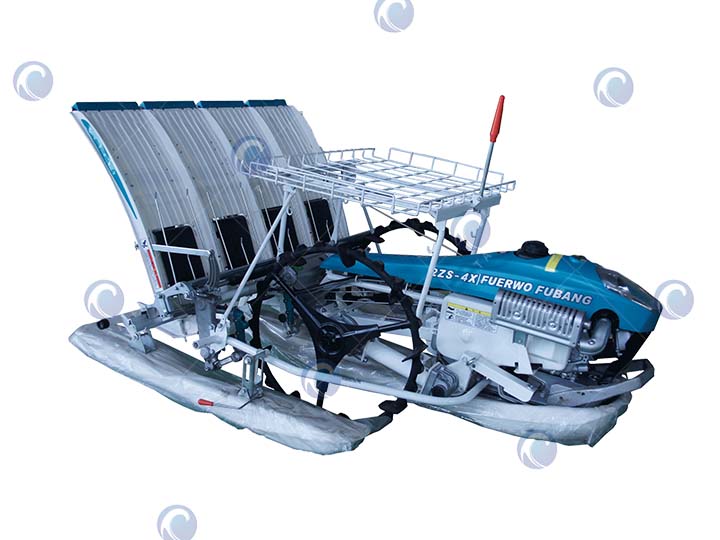

Rice nursery seeder match with rice transplanting machine

After the rice seedlings are completed, the rice transplanter machine needs to be used for transplanting.

Below is the walk-behind rice transplanter.

Operation video of rice transplanter

We can customize a 2-row, 4-row, 6-row, or 8-row rice transplanter according to your rice nursery seedling machine.

Rice nursery sowing machine shipped to Pakistan

The customer is from Pakistan and he has a special greenhouse to grow rice. The customer has been using traditional planting methods before. To improve the efficiency, he was looking for a professional rice nursery seedling machine.

He wanted to know more about the rice nursery seedling machine by reading our website. Our sales manager communicated with the customer via WhatsApp. And our sales manager gave prompt and professional answers to all questions. Finally, the customer decided to buy from us.

FAQ about rice nursery seedling machine

Can this rice seeder nursery other vegetables?

No, this is a nursery seeding machine specifically for rice. We have a special vegetable seeding machine.

Which countries have you exported to?

To be a specialized agricultural machinery manufacturer, our rice nursery seedling machines have been exported to Azerbaijan, Uganda, Kenya, Indonesia, and so on.

What should I do if the rice nursery seedling machine is broken?

First of all, we have a one-year warranty. Secondly, we will be equipped with wearing parts and toolboxes. The point is that the machines we exported did not have such problems.