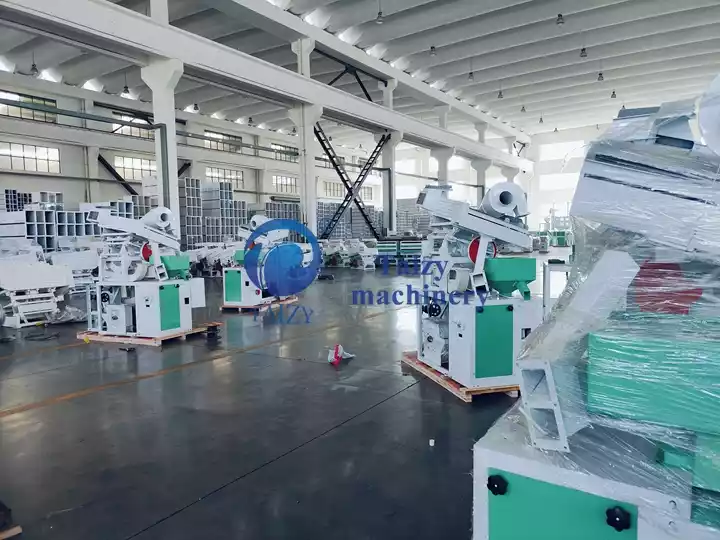

Good news! Our company has once again sent 4 sets of small rice milling lines with a capacity of 15 tons per day to a customer in Ghana. All the machines were finished in the middle of this month and successfully packed and shipped.

Customer background and requirements

This customer is the operator of a rice processing plant on a large scale. Previously, due to the uncertainty of the performance of the machine, he only purchased 3 sets of small rice milling lines for trial.

After a period of use, the customer is very satisfied with the performance and quality of our products and thinks that our rice milling unit is efficient, stable, and fully meets his production needs. Therefore, the customer decided to purchase 4 sets of rice milling machines again to expand the production scale and improve the processing efficiency.

For information about this Ghana customer’s first purchase, you can click to view: 3 Sets of Small Rice Mill Lines Delivered to Ghana.

Small rice milling line details and after-sales support

After many tests and feedback from customers, the equipment runs stably and has a low failure rate. The rice milling process is fine, ensuring high quality and good taste of the finished rice.

- Capacity:15TPD/24H (600-800kg/h)

- Power:23.3kw

- Packing Volume: 8.4cbm

- Weight: 1400kg

We also provide the following spare parts to ensure the stable operation of the machine for a long time: 8pcs of rubber roller for paddy rice husker, 24pcs of rice milling sieves, 20pcs of press bar, and 4pcs of emery roller.

Why choose our company?

After the customer purchased and used our small rice milling lines for the first time, he highly praised our service and technical support.

We ensure that our customers can fully understand and skillfully operate the equipment through detailed product introduction, video demonstration, and on-site training.

In addition, our after-sales team is always on standby to provide comprehensive after-sales support, solving any problems encountered by customers in the process of using the equipment and ensuring smooth production.