Corn Stalk Reaping Machine Maize Straw Reaper For Harvesting

Corn Stalk Reaping Machine Maize Straw Reaper For Harvesting

Corn straw reaper | Maize stalk harvesting machine

Features at a Glance

The corn stalk reaping machine is also called maize straw reaper and corn stalk reaper. It harvests upright corn stalks in the field when the corn is mature or close to maturity.

It has a clamping chain conveying device. The harvested straws are laid horizontally in bundles at the rear or right rear of the tractor. It applies to the waxy harvest of straw with a spike or ear of corn without producing areas and livestock breeding areas.

Corn stalk reaper machine working principle

During operation, the corn stalk reaping machine advances along the corn ridge. And the cutting knife cuts the corn stalks. The stalks are output from the right side of the upper, middle, and lower conveyor chains and placed naturally to complete the harvest.

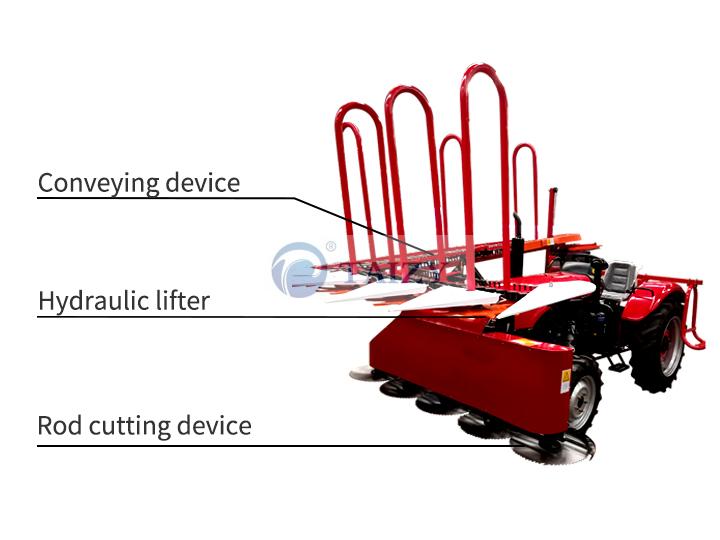

Structure of the corn stalk harvester machine

The corn stalk reaping machine consists of a rod-cutting device, a conveying device, a hydraulic lifter, and so on. They respectively arrange in front of and on the right of the tractor.

It is cut with a saw blade and adopts the form of clamping and conveying. It can directly harvest the upright straw in the field. And put the straw into bundles on the right side of the tractor.

Advantages of corn stalk chopper machine

- There is no need to clear the road manually during operation, which saves labor and improves labor efficiency.

- The cutting head is controlled by the oil cylinder to control the height of the stubble.

- The harvested straws are laid out neatly in the same direction, which is convenient for collection, storage, and transportation.

- The harvesting efficiency is high, 5-10 acres can be operated per hour.

- The cutting method is the overlapping and staggered cutting of saw blades, the cutting speed is fast, the cutting is complete, and no dead corners are left. The stubble is neatly cut and the vibration is small.

Machine parameters

| Supporting power | single-cylinder small four-wheel tractor with more than 20 horsepower |

| Operation efficiency | 5-10acres/hour |

| Whole machine weight | 510kg |

| Connection form | hanging |

| Theoretical harvest line spacing | 550-650mm |

| Harvesting width | 2.2meters (4 rows theoretically) |

| Power source | single cylinder: belt pulley, rear-wheel; multi-cylinder: rear output shaft, rear-wheel |

| Conveying method | clamping and conveying |

| Maximum height of saw blade from the ground | 300mm |

| Components | cutting rod device, conveying device, hydraulic lifter |

Difference between corn stalk reaping machine, straw crushing and recycling machine

Corn stalk reaping machine

Maize straw reaper is a special type and purpose harvester. It is to harvest the straw with or without ears and spread it flat behind or behind the machine for easy collection. It can be used not only to harvest corn but also to harvest pasture. And it can harvest the straw directly in one piece.

Straw crushing and recycling machine

The straw crushing and recycling machine has the function of crushing and recycling. It is suitable for upright or fallen crop straw. The machine directly crushes the straw. After that, the crushed straw comes out through the discharge port and falls into the storage box.

You can directly use the green straw harvested by the straw crushing and recycling machine to make silage. And use the dry straw to make biomass fuel. You can also use it as a nutrient for edible fungus.

Both types of straw harvesters have their advantages and uses. You can choose according to your needs. At the same time, we can also recommend the most suitable model for you according to your needs.

Machine factory display

Precautions for use

- Debug the machine before the operation to ensure that the machine is in good working condition.

- You can adjust the height of the stubble by adjusting the screw of the lifting frame. Before harvesting, adjust the cutting knife to touch the soil and ground and then lock the screw for a trial cut to see if the cutting condition is suitable. If it is not suitable, adjust it to meet the requirements and start harvesting. Generally, the recommended height of the stubble is greater than 3-5cm to avoid damage to the cutter.

- Check whether the gearbox is short of oil before harvesting, and if there is a shortage of oil, add oil in time. After the chain has been working for some time, there is also a drop of lubricating oil.

- Besides, the method of harvesting to improve efficiency is to harvest in circles around the plot.

- After using the cutter for some time, the cutting edge part of the cutter wears and becomes blunt. At this time, use a hand-held grinder to sharpen the cutting edge to help save power during harvesting. However, when sharpening the cutting edge, prevent overheating and dripping to cool down, so as not to reduce the durability of the cutting edge.

Maintenance of the machine

After the machine operation is completed, inspect the machine in time. Check if there is any damage during the operation of the machine. If it is found, repair and maintain it immediately.

When the machine does not operate for a long time and needs to be stored, lubricate the bearings and conveying parts to prevent the machine from rusting and affecting its use.