Grain needs multiple steps from harvest to storage. After harvesting the grain, people will send the grain ears to the thresher. During the threshing process, there will be many impurities in the crops. Therefore, it is also necessary to remove the impurities in the grain particles after the threshing. Then carry out a series of processing, and finally put it into the warehouse for storage. The following are the main steps before storage:

Remove impurities in crops

- The traditional method of removing impurities is spreading in the crosswind direction. The aim is to make dust, broken leaf veins and other debris drift away with the wind. At that time, science and technology were not very developed. After that, impurities such as wheat and stalk husks are separated.

Splattering grains

Splattering grains

2. Dustpan is a kind of agricultural tool, its function is to dust off the impurities and empty shells in the grain. Generally, the negative pressure formed by the downward movement of the dustpan fan out the lighter impurities; the intention of the rough texture of the dustpan is to separate the small impurities and bump them out. Generally, impurities that are lighter than grains are sifted out, and small stones and soil blocks that are heavier than grains are manually selected.

Dustpan

Dustpan

3. The traditional method is more troublesome. With the advancement of science and technology, more and more farmers use electric lifting machines and screening machines to remove impurities, which solves the problem of removing debris in large grain warehouses. The grain winnower machine is a kind of equipment for simple cleaning of grains, which can remove light impurities and large impurities in the grains to facilitate the storage of grains.

Seed-winnower

Seed-winnowing-machine

Reduce moisture of crops

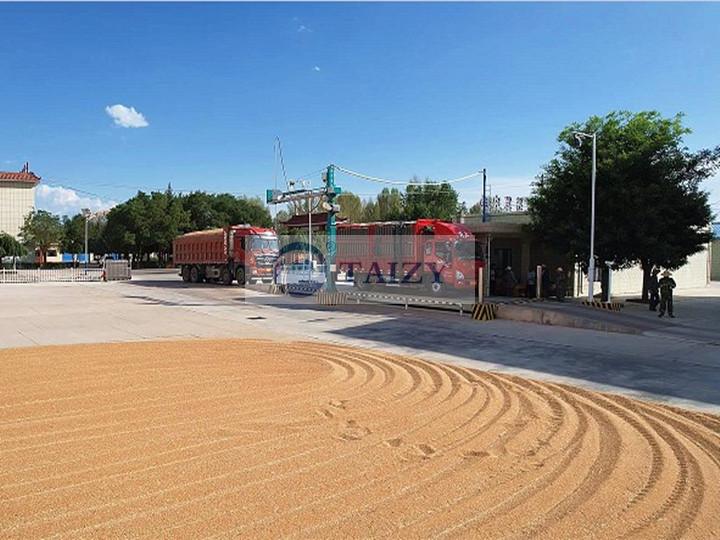

After harvesting the crops, the moisture content is very high, and direct storage will produce mildew. Reduce the moisture in the grain generally through the method of drying. Drying should choose a sunny day, the best time is to start after nine o’clock in the morning and end before three o’clock in the afternoon. When drying, the drying thickness of wheat and rice is about 10 cm; corn and soybeans are about 15 cm so that a good drying effect can be achieved.

Collect the grains that have been air-dried that day as soon as possible and cover them with waterproof materials. The purpose is to prevent the grains from absorbing moisture again after the temperature drops. After continuous drying, the grain precipitation will reach the warehousing standard. Under conditions, you can also use a professional grain moisture dryer for precipitation treatment. The grain after the precipitation treatment can proceed to the next step.

spread grain

dry grain

Moisture detection

In order to measure the moisture content more accurately, we can use a fast moisture detector to detect moisture on site. Moisture detectors include plunger type, a resistive type, capacitive type, etc. Here we introduce how to use them:

- Plunger-type moisture detector: insert its sampling plunger into the grain pile, and the meter can display accurate values.

2. Resistance-type moisture detector: a certain amount of sample is obtained from the grain pile with a sampler and sent to the instrument. If you turn on the switch of the instrument clockwise, the moisture content value will appear.

3. Capacitive moisture detector: place the grain sample in the moisture detector with a measuring cup, then press the detection switch, the moisture content of the grain will display.

In order to improve the accuracy of the measurement data, no matter using which method, choose several samples for measurement and take the average value as the final measurement result.

Empty warehouse disinfection

Before storing grains, in order to prevent pests, clean the warehouses firstly and then disinfect them. Since the medicine is a chemical agent, in order to prevent the grain from being contaminated during storage, 48 hours after the disinfection is completed, open the window for ventilation, and put the grain into the warehouse after 24 hours.