Round Silage Straw Harvester And Baler, Picking And Bundling Machine

Round Silage Straw Harvester And Baler, Picking And Bundling Machine

Straw picking and baling machine | Crop harvesting baler

Features at a Glance

The round straw harvester and baler machine integrate shredding, picking, and bundling. It has the advantages of small size, lightweight, compact structure, convenient operation, and high work efficiency. The machine is suitable for use in various farms, pastures, and straw recycling sites.

It can separately complete the harvesting, picking, and bundling of various dry and wet straws. During use, we can adjust the length and size of the bundle according to the needs of transportation and storage.

This round straw harvester and baler machine is for the fuel supply and storage of straw power plants. And also is a good helper for large-scale breeding enterprises.

Round straw harvester and baler machine applicable scope

Alfalfa, Leymus Chinensis, reed, cotton stalk, corn stalk, wheat stalk, etc.

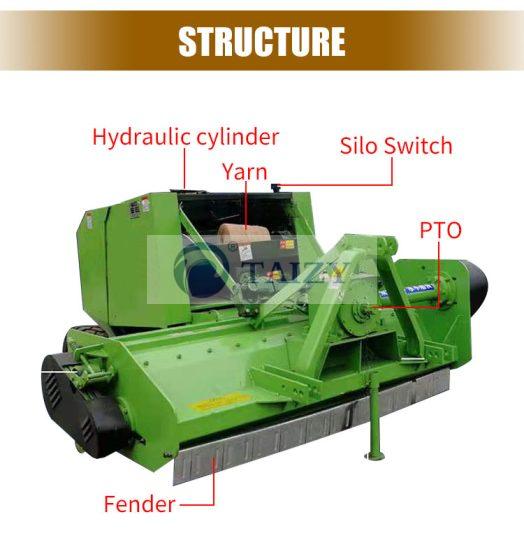

Structure of the forage crushing pick up baler

This round straw harvester and baler machine includes a PTO, crushing mechanism, picker, feeding mechanism, bundling mechanism, and other parts.

- PTO: connect to the tractor through a splined shaft (8 keys). First, start the tractor. And then transmit the power to the machine through the spline shaft.

- Crushing mechanism: breaks up the straw first.

- Picker: picks up and lifts the crushed straw into the feeding platform.

- Feeding mechanism: feeds the straw into the baling mechanism.

- Bundling mechanism: the piston and baling chamber compress and form the straw.

How does the silage cutting, picking and bounding machine work?

Firstly the round straw harvester and baler machine kneads and crushes the straw first. After that, the material is thrown into the auger under the inertia of the machine. The auger pushes the material to the feeding port.

Then the feeding fork sends the material into the compression chamber of the round straw harvester and baler machine.

Finally, the warehouse is hydraulically opened and bundled. The bundled forage is convenient for transportation, storage, and further processing.

The power output shaft of the tractor inputs the power to the input shaft of the round straw harvester and baler machine through a Cardan shaft.

After that, the sprocket and chain drive the rolling and pressing roller mechanism and the straw picking mechanism respectively.

Then we use the tractor hydraulic output interface to control the expansion and contraction of the cylinder piston to realize the bale unwinding operation.

Parameter of automatic corn stalk harvester and baler machine

| Model | Recovery width(mm) | Work efficiency(acre/day) | Power(kw/ml) |

| 9YY-0.5 | 1650 | 30-50 | >50 |

| 9YY-0.7 | 1800 | 50-90 | >50 |

Characteristic of round stalk crushing, picking and strapping machine

- There are two picking widths, which can adapt to different width operations.

- The compression mechanism is located on the upper part of the pickup mechanism. Therefore, the width of the equipment is smaller for the same picking range. It is more convenient for small field operations. The overall layout is more reasonable.

- The four-wheel tractor is used for positive traction operation, and the operation is stable.

- There is a safety clutch work with a power input part. The main drive shaft, compression device, and rope binding device are all working with safety bolts. When the system load is too large, the bolts are automatically cut to cut off the power transmission of the tractor. So that it can protect the system from damage.

Why choose our straw cutting, picking and strapping machine?

- It can harvest straw, hay, wheat straw, alfalfa, and other cereal stalks, with a wide range of applications.

- The machine has a simple structure, low failure rate, reliable work, easy operation, small bundle shape, and easy handling.

- Because it is a hang-up method. So it is suitable for small and medium horsepower tractors. Therefore, it has good flexibility, especially in small plots.

- After the bale is formed, the hydraulic system of the tractor controls the oil cylinder to open the rear frame and spit out the bale.

- It has easy maintenance, a low failure rate, good reliability, and a high bundling success rate.

- The feed opening of this machine is wider than other models. It can solve the transportation and storage problems of straw for the majority of farmers and professional households.

Contact us at any time

When you choose to use the round straw harvester and baler machine, if you have any questions or need further information, we are always ready to provide you with advice and services. We also have square bale straw pickup balers available. We are eagerly looking forward to establishing a cooperative relationship with you and jointly promoting the progress and development of agricultural machinery technology!