Peanut Harvesting Equipment丨Groundnut Harvester Machine

Peanut Harvesting Equipment丨Groundnut Harvester Machine

Peanut Harvester Machine | Groundnut Digger Machine

Features at a Glance

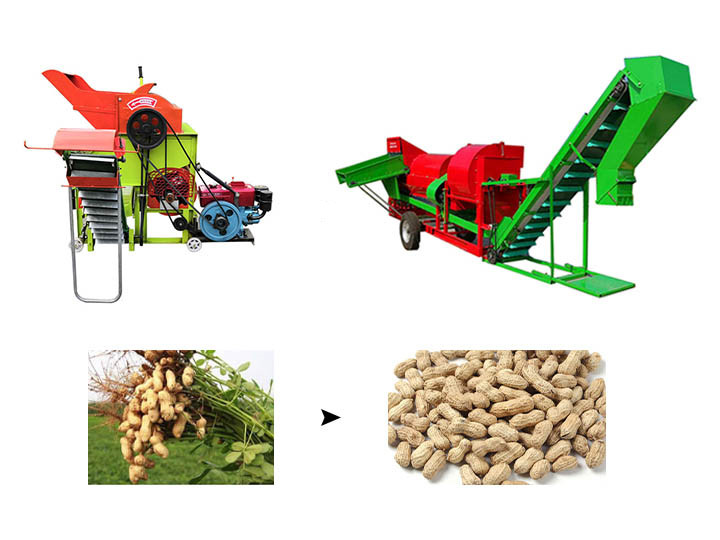

The peanut harvesting equipment is designed to improve peanut harvesting efficiency and reduce labor costs. The machine can be used with a 20-35 hp tractor and can easily cover 1300-2000 square meters per hour.

It has a fruit picking rate of more than 98% and a fruit breakage rate of less than 1%, effectively improving peanut yield and quality.

In order to meet the planting needs of different farmers, the peanut harvesting equipment supports 180-250mm row spacing adjustment, easy to operate.

Meanwhile, we also provide a full set of peanut processing equipment, such as peanut seeder, peanut picker, peanut sheller, etc., which can help you easily complete the whole process from seeding to processing.

Peanut harvesting equipment’s main structure

The peanut harvesting equipment is mainly made of a frame, power, transmission part, selection part, vibration device, ground wheel, digging blade, roller chain, bevel outlet, etc.

The peanut harvester has a high working efficiency and can neatly discharge the harvested peanuts to one side, which is beneficial for people to harvest. The following is an example of a small peanut harvester showing structural details.

Technical parameters of groundnut harvester

| Model | HS-800 |

| Power | 20-35HP tractor |

| Capacity | 1300-2000m2/h |

| Harvest width | 800mm |

| Weight | 280kg |

| Size | 2100*1050*1030mm |

| Packing rate | ≥98% |

| Breaking rate | ≤1% |

| Cleaning rate | ≥95% |

| Harvester width | two rows |

| Distance between rows | 750-850mm |

| Row spacing | 180-250mm |

| Dimension | 2100*1050*1030mm |

The peanut harvester machine’s body is waggling during operation.

- Reason: the digging shovel swings inconsistently or collides with hard objects such as stone.

- Solution: adjust the swing angle of the digging shovel.

Harvested peanuts contain much dirt and are not shaken off.

- Reason: the digging depth is so deep that swing strength is reduced.

- Solution: adjust the length of the central rod. Properly shorten the length of the central tie and keep it within 3-5 cm away from the ground.

Peanut fruit falls on the ground and needs to be picked up by hand again.

- Reason: the shovel is lifted excessively.

- Solution: the length of the central tie rod can be extended.

Peanut harvesting machine advantages

- Peanut seedlings are conveyed to the back outlet quickly after harvesting by a roller chain, which prevents them from sinking into the soil.

- There are no impurities after harvesting because the vibrating screen plays an essential role in collecting peanuts and can make the product cleaner.

- Groundnut harvesters can be operated flexibly even in a field with a lot of water, which can meet different field situations.

- Shoveling soil at a specific angle can fully harvest fruits with sharp blades. So do not worry about there being many fruits left in the soil.

- Peanut harvesters for sale can work with high efficiency, saving much labor time. And meanwhile, we can operate the machine easily.

- Peanut harvesting runs steadily during operation. Farmers can complete the peanut harvesting work. Also, this peanut harvester has a long service life, and people can use it for many years.

Working principle of peanut harvester

- The operator connects the groundnut harvesting machine to the tractor first. Carefully read the operation manual before using it.

- Digging a shovel of a peanut harvester with a sharp blade shovels soil at a certain angle.

- Peanut seedlings are harvested from the soil and then placed on the two sides of the machine.

- The seedlings are transported to the back position by a roll chain and roller, which can protect peanut plants from sinking into the soil and make it easy to dig.

Successful case

Last week we exported a peanut harvester to Botswana. The customer needed a small groundnut digger harvester. Our sales manager reached out to the customer and recommended this machine.

During the entire communication process, the customer is primarily concerned about the width of the machine’s harvest. Our machine’s harvesting width is 800mm (two rows), which fulfills the customers’ requirements. The diagram below illustrates the packaging and delivery of the peanut harvesting equipment.

FAQ of groundnut harvesting machine

Are you a manufacturer?

Yes, we are. Welcome to visit our factory.

Can you change the machine voltage as per our request?

Yes, we can.

How about your after-sales service?

Our engineer can go to install and train your workers to operate.

Warranty time of your machine?

1 year except for consumable spare parts.

How about the delivery time of your machine?

Generally, it needs 5-15 days for big machines or production lines, and it will be much longer but within our negotiated delivery time.

How many rows does this peanut harvesting machine can do?

Two rows.

Does the machine hurt the peanut fruits during the operation?

No, the machine just the peanut from the soil and won’t hurt the peanut fruits.

What is the loss rate?

The loss rate is less than 2%, and almost all peanuts can be harvested at one time.

Which machine do I need if I want to pick the peanut fruit from the seedlings?

If you need a peanut picker machine, please contact us to learn more.