Combined Peanut Cleaning And Shelling Machine

Combined Peanut Cleaning And Shelling Machine

Combined peanut sheller | Groundnut cleaner and sheller

Features at a Glance

The combined peanut shelling machine is suitable for peanut and grain processing factories, peanut oil pressing factories, etc. Its output is from 800kg/h to 8000kg/h, the shelling and cleaning rate is up to 99%, and the loss rate is less than 0.5%. The peanut breaking rate is less than 5%.

The peanut kernel produced by this combined peanut shelling machine is cleaner due to its integrated cleaning system. Whenever the machine is activated, the cleaning mechanism first ensures the peanuts are thoroughly cleaned. Throughout this process, various impurities such as stones, sand, and peanut seedlings are effectively removed.

Five models of combined peanut sheller machine

We have five models of large-yield peanut shellers, and their output is different. They are 6BHX-1500, 6BHX-3500, 6BHX-20000, 6BHX-28000 and 6BHX-30000. These combined peanut shelling machines use the principle of hierarchical peeling, first peeling large peanuts, and then peeling small peanuts. This improves the peeling rate and reduces the damage rate.

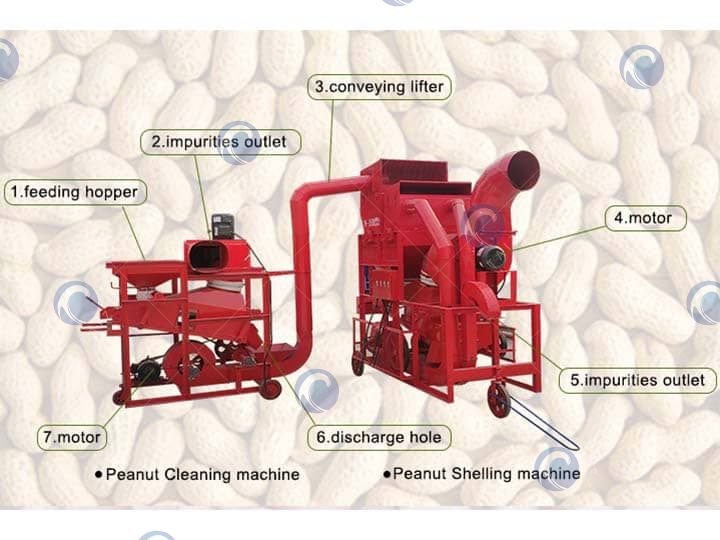

Large peanut sheller and cleaner structure

The large peanut sheller mainly includes the feeding hopper, impurities outlet, discharge hole, power, peanut kernel discharge port, universal wheels, etc.

The main components are the mainframe, the feeding hopper, the screen with the left and right spiral plates, the rollers, the conveying lifter, pipes, etc, of which the number of drums and screens can be customized according to your requirements.

Characteristics of our combined peanut shelling machine

- The combination of a closed-screen box and a dedicated fan achieves suspension sorting. The movable screen on the side is a historic breakthrough for the combined peanut shelling machine.

- The stem-removing system setting reduces functional consumption, protects the internal structure of the sheller, and accelerates transmission efficiency.

- At the same time, this peanut sheller is simpler in structure more environmentally friendly, and is the ideal equipment for peanut processing farmers.

Peanut shelling and cleaning machine technical parameters

| Model | 6BHX-35000 | 6BHX-28000 | 6BHX-20000 | 6BHX-3500 | 6BHX-1500 |

| Capacity (kg/h) | ≥8000 | ≥6000 | ≥5000 | ≥2000 | ≥1000 |

| Dimension(mm) | 2785*1900*3260 | 2750*1800*3360 | 2650*1690*3360 | 2500*1200*2450 | 1500*1050*1460 |

| Total Weight(kg) | 2750 | 2380 | 2270 | 1200 | 550 |

| Cleaning Motor | 5.5kw, 7.5kw | 5.5kw;5.5kw | 5.5kw,5.5kw | 3kw,3kw | 1.5kw 1.5kw |

| Shelling Motor | 11kw,7.5kw,5.5kw, 18.5kw | 15kw,4kw,15kw | 11kw;4kw,11kw | 5.5kw,4kw | 1.5kw,3kw |

| Cleaning Rate(%) | ≥99 | ≥99 | ≥99 | ≥99 | ≥99 |

| Shelling Rate(%) | ≥99 | ≥99 | ≥99 | ≥99 | ≥99 |

| Loss Rate(%) | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 |

| Breakage Rate(%) | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 |

| Humidity(%) | 10 | 10 | 10 | 10 | 10 |

How to properly use a combined groundnut shelling machine?

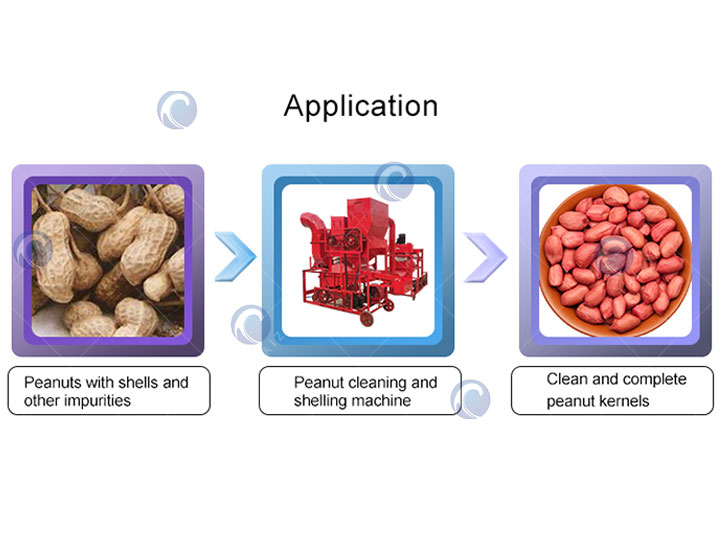

Start by connecting the peanut cleaning machine to a combined peanut shelling machine. Next, place the peanuts, which contain various impurities, into the cleaning machine.

After a few minutes, the cleaned peanuts will move on to the shelling machine. The separation of the peanut shell from the kernel occurs through repeated impacts, friction, and collisions with the rubber roller.

Peanuts that are smaller than the holes in the screen will be directed to the next layer for a second shelling. If your combined peanut shelling machine has four layers of screens, the smaller peanuts will continue to drop down to the next layer until all the shells are completely removed.

After that, three powerful fans will blow away the shells and impurities. Finally, the clean peanut kernels will be discharged through the outlet. You can also connect a long vibrating screen at the end of the outlet to achieve even cleaner peanut kernels.

What is the role of a peanut cleaning machine?

Typically, the combined peanut shelling machine can be used right away, but most suppliers primarily offer peanut shellers. However, during harvesting, peanuts often come with soil clumps, stones, peanut leaves, dust, and other debris.

If these impurities are not removed, they can lead to a significant number of peanuts being damaged, which affects their appearance, and can also harm the machine’s components.

To address this issue, we developed a specialized peanut cleaning machine that attaches to the side of the peanut sheller, significantly enhancing the cleaning efficiency. Its cleaning rate exceeds 99%.

Requirements for shelled peanuts to be used as seed

- After harvesting, you should avoid shelling peanuts too early, as this can cause the seeds to lose the protective husk, making them more susceptible to moisture in the air and decreasing their survival rate.

- Once the peanut shell is removed, the kernel is exposed to air, which can lead to oxidation. This process often darkens the color of the peanut skin to a dark red.

- It’s important to place the shelled peanuts in a plastic bag or a sealed container right away; otherwise, exposure to moisture can negatively impact the germination rate.

- Peanuts should not come into contact with fertilizers or pesticides, and they should not be smoked with coal.

What’s more, we also have a peanut shelling machine without cleaning equipment. People can also use the peanut picker machine before using the sheller machine. Please ask us for more information.

FAQ

What’s the capacity of the combined peanut shelling machine?

Its capacity ranges from 800kg/h-8000kg/h.

Can I only buy a peanut cleaning machine?

No, you can not, it must match with the peanut sheller.

What is the cleaning rate of the peanut cleaning machine?

More than 99%.

Can the peeled peanut kernels be used for seeds?

Yes, of course.

How many layers of the screen are inside the combined peanut shelling machine?

The number of the screen can be 1 layer, 2 layers, 3 layers, or 4 layers, and we can customize it according to your demand. What’s more, it is movable.

What is the humidity of peanuts better for peeling?

The suitable moisture is 13%-14%. The drier the peanut, the lower the breakage rate.

What is the combined groundnut shelling machine price?

Zhengzhou Taizy Machinery Co., Ltd is a large-scale enterprise focusing on R&D and sales of agricultural machinery. There are various models of peanut shell removing machines that can meet the different needs of customers, and now we are sold in dozens of countries. Tell us your needs, and we will customize the peanut sheller machine for you.

Successful cases of peanut shelling units

Our client is from Brazil. This customer found our peanut sheller by exploring our website. Once we received their contact information, we promptly reached out to them.

From what we’ve gathered, this customer cultivates a significant area of peanuts, and after each harvest, they hull and sell them to the local grain harvester.

In the past, they used a small peanut sheller that lacked a cleaning machine. This time, the customer specifically requested a sheller that includes a cleaner.

After discussing their needs, we suggested the 1500-type sheller. Ultimately, the customer decided to purchase the machine. Below is the packaging and delivery diagram for the machine.

Our professionalism is also one of the most important reasons to gain the trust of our customers. The following shows more countries’ shipments and related certificates.

We warmly invite all customers to actively consult and discuss with us how to use combined peanut shelling machines to improve production efficiency and reduce costs.