Peanut Sheller shelling machine / groundnut sheller factory

Peanut Sheller shelling machine / groundnut sheller factory

Peanut huller/Peanut husking machine

Features at a Glance

Brief Introduction of Peanut Sheller Machine

The peanut sheller machine mainly removes the shells of the peanuts, that is, through the high-speed rotating body the shells of the peanuts, and the peanuts are kept intact. The peanut sheller machine is also called the groundnut sheller or groundnut shell removing machine.

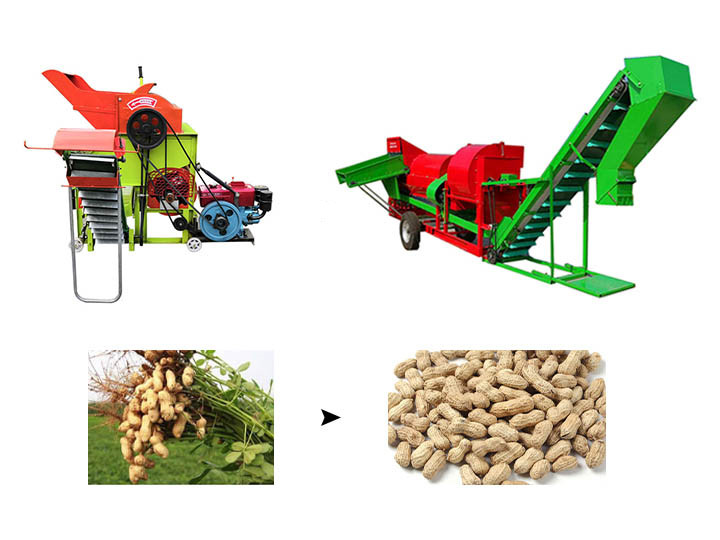

We have 2 types of peanut shelling machines, and different types bear different capacities, that is,200kg/h, and 600-800kg/h. You can choose the smaller one for home use, and both have great performance when working.

Type one(200kg/h)

Technical parameter of peanut sheller machine

| Model | TBX- 200 |

| capacity | 200kg/h |

| Size | 650*560*1000mm |

| Weight | 40kg |

| Engine | 2.2kw motor, gasoline engine or diesel engine |

Detailed pictures of peanut sheller machine

Type two(600-800kg/h)

Technical parameter of peanut sheller machine

| Model | TBH-800 |

| Power | 3KW Motor or gasoline engine or diesel engine |

| Size | 1330x750x1570mm |

| Capacity | 600-800kg/h |

| Weight | 160kg |

Working principle of peanut sheller machine

1. Operator places peanuts into the inlet by hand after the machine is idling for several minutes.

2. Peanuts fall into rubber roller. Due to the force between the rotation of the rubber roller, the peanut kernels and the shells are separated.

3. Then peanuts simultaneously drop on the grid, and shells are blown out through the wind.

4. As for the smaller peanut sheller machine, the process is finished and you can get clean peanut kernels.

5. Regarding to big size peanut sheller, some peanuts that have not been peeled off fall into the specific gravity sorting screen. Such peanuts with shells are conveyed by a plastic lifter and then go into the roller to be shelled again. Finally, the kernels drop into the container.

Requirement of peanut sheller machine

1. Requirements for the groundnut sheller machine. It is forbidden to drop any hard objects into the machine.

2. Requirements for peanuts. Peanuts should not be too dry and wet, which will cause a low shelling rate and affect working efficiency respectively

Advantage of peanut sheller machine

1. Peanut Sheller integrates peanut shelling, air delivery, and separation as a whole and works with high efficiency(600-800kg/h). The shelling rate can reach 97% or more.

2. Four wheels make it easy to move.

3. Low breakage rate. All peanuts can be unbreakable after shelling

4. High cleaning rate. There is a baffle at the exit of peanut kernels, and it can effectively block the peanut shell from coming out, improving the cleaning rate.

5. Rather than adopting a steel roller, a rubber roller does not exert damage to the peanut itself.

6. Thanks to the plastic lifter at the side of the machine, small peanuts and peanuts that are not fully peeled off can be shelled again.

Precautions of peanut sheller machine

1. During operation, impurities such as iron filings, stones, and other hard objects can not be placed into the inlet.

2. The screen inside the machine should fit the size of a peanut, otherwise, some peanuts may not be fully shelled.

3. It is necessary to please a fan baffle, which not only increases wind blowing but to reduces the shells mingled in the peanut kernels.

4. Confronting with more than a 5% breakage rate, the operator had better increase the gap between rollers, but it should be within 25~40 mm.

5. Check whether the machine is damaged before work.

6. During operation, the operator should close the inlet and open 1-2cm to allow the peanuts to come out when the screen is full.

7. Normally, the screen must remain full when working, otherwise some peanuts won’t be fully shelled.

8. If peanuts fall down the outside of the outlet, the operator should adjust the wind deflector outward, or close the air inlet.

9. If the breakage rate is high and red skin is removed. Peanut is too dry spray water on the peanut and shell them later.

10. There are four positioning bearings on both sides of the machine, and add butter to the middle of the sieve and the bearing every four hours when working.

Successful case of peanut sheller machine

Last year, we exported 70 sets of peanut sheller machines to Nigeria and received good feedback from our customers. He is a dealer and sold them to local farmers.

Our peanut sheller machine helps them improve working efficiency as well as life standards. We hope every farmer can benefit from our machine and their life can become better and better.

FAQ

Are the functions of the two types of peanut shellers the same?

Yes, you can get clean peanut kernels after threshing.

what is the difference between the two types?

Smaller size peanut shellers don’t have a lifter that the other has. In addition, the capacity is different.

what is the delivery time?

We have two types in stock and can deliver them to you at any time.

What’s the breakage rate?

Less than 5%.

which countries have you exported these machines to?

We have exported to many countries, especially the African market.