Electric & Gase Peanut Roasting Machine Groundnut Roaster For Sale

Electric & Gase Peanut Roasting Machine Groundnut Roaster For Sale

Peanut Roaster | Groundnut Roasting Machine

Features at a Glance

The peanut roasting machine is mainly used for roasting or drying groundnuts, walnuts, almonds, beans, coffee beans, melon seeds, and other granular materials and powders.

This machine uses electric heating, oil, gas, or coal as the heat source. It adopts a rotating drum, heat conduction, and heat radiation principles, and uses coal as fuel, the production cost is low. The machine has the advantages of easy use, high efficiency, energy saving, and durability. The baked products are of good quality, hygienic taste, and can meet export standards.

How does the peanut roaster machine work?

The working principle of the peanut roasting machine is divided into the following steps:

Loading

Peanuts are placed at the entrance and enter the baking chamber through a conveyor belt or other means.

Preheat

Before the peanuts enter the baking chamber, the machine will preheat briefly. This ensures that the entire system is at the proper temperature for an efficient baking process to begin. Generally set at room temperature 300 degrees.

Roasting

Peanuts are roasted for a certain period in the baking chamber through hot air or radiant heating. The control of temperature and time is very critical to ensure that the peanuts are heated evenly and achieve the desired taste and color.

Cooling

After baking, the roasted peanuts need to be cooled in the machine. This stage helps stabilize the temperature of the peanuts while ensuring they don’t overheat and affect their quality.

Unloading

The cooled peanuts finally leave the machine and can be collected by conveyor belts or other systems or entered into subsequent processing stages.

Parameters of peanut roasting machine

| Model | Dimension(mm) | Capacity(kg/h) | Power(kW) | Electric Heating Power(kW) | Gas Consumption(kg) |

| MHK—1 | 3000*1200*1700 | 80—120 | 1.1 | 22 | 2-3 |

| MHK—2 | 3000*2200*1700 | 180—250 | 2.2 | 44 | 3-6 |

| MHK—3 | 3000*3300*1700 | 280—350 | 3.3 | 66 | 6-9 |

| MHK—4 | 3000*4400*1700 | 380—450 | 4.4 | 88 | 9-12 |

| MHK—5 | 3000*5500*1700 | 500–650 | 5.5 | 110 | 12-15 |

Multiple types of machines

Our factory produces roasters with 1-5 cylinders. In addition, besides the drum type, we can also provide conveyorized continuous roasters as well as integrated roasting and cooling machines.

Depending on your needs for machine size and output, we can manufacture different types to meet your needs.

The following are two types of peanut roasting machines, single-cylinder and double-cylinder. These two are also the hottest-selling machines.

Single-cylinder peanut roaster

Double-cylinder groundnut roasting machine

Groundnut roasting machine main benefits

- Even roasting: the peanut roasting machine adopts advanced drum technology to ensure that the peanuts are heated evenly, avoid over-roasting or undercooking problems, and ensure a consistent taste of the product.

- Intelligent control system: equipped with an intelligent temperature and time control system, which makes the operation easier, the production process more controllable, reduces human errors, and improves production efficiency.

- High production efficiency: through automated processes and continuous operation, the peanut roasting machine can complete mass production in a short time, improving production efficiency and reducing production costs.

- Multi-functional design: it is suitable for roasting nuts of different types and specifications, and has strong versatility, making it an ideal choice for food processing companies to flexibly respond to market demands.

- Stable product quality: the machine’s precise temperature control and operating system ensure the consistency of the roasting quality of each batch of peanuts, providing manufacturers with more reliable products.

Groundnut roasting machine successful cases

Our peanut roasting machine has been successfully shipped to many countries, such as Ghana, Tanzania, Pakistan, Bangladesh, Germany, etc. The picture below shows you the machine packaging and shipping diagram.

Recently, we successfully dispatched two units of our peanut roasting machine to a customer in Ghana. This customer operates a bustling snack business, specializing in the production and sale of roasted peanuts and other nut-based snacks.

With our machine, they aim to meet the growing demand from local markets while expanding their product offerings to include innovative snack variations.

Contact us at any time

If you are interested in this peanut roasting machine, then please feel free to contact us. We will send you more details and a quotation.

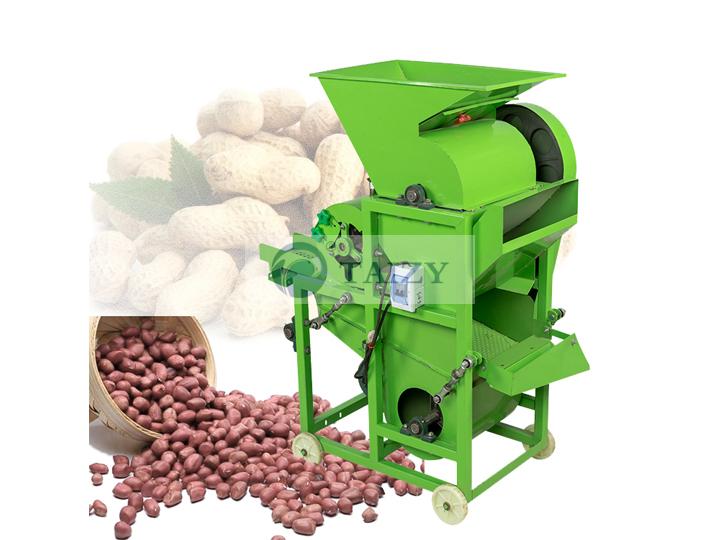

To comprehensively improve your production chain, we also recommend other peanut-related processing machines from our company, including peanut seeders, groundnut harvesters, peanut shelling machines, etc., to ensure that you have a complete solution.

You are welcome to visit our factory to experience and understand these innovative technologies firsthand. Let us work together to help you achieve greater success in your peanut industry journey!