Peanut Sheller Removing Machine For Groundnut Harvesting

Peanut Sheller Removing Machine For Groundnut Harvesting

Groundnut Shell Removing Machine | Peanut Shelling Machine

Features at a Glance

This peanut sheller removing machine is designed for efficiently handling large quantities of groundnuts and is suitable for all types of farms and food processing plants. The machine can quickly strip peanut shells and ensure that peanut kernels are intact, with an output of up to 800-1100kg/h.

Brief introduction of peanut sheller removing machine

As a common crop, peanuts often appear in people’s daily lives. The shell of peanuts is inedible, and artificial threshing is difficult, so more and more users are buying peanut sheller removing machines.

Our peanut sheller removing machine has many improvements to the original peanut sheller machine and it can use gasoline, diesel, and electricity to get power. Compared with manual threshing, removing groundnut shells from peanut shellers can greatly reduce the labor of farmers, save a lot of manpower, and greatly improve work efficiency.

Structure of groundnut thresher machine

Our groundnut shell removing machine consists of five main parts: import, diesel engine, export, big tires, and traction frame. Our groundnut thresher has a diesel engine, which can be powered by diesel and it can meet the needs of customers who are accustomed to using diesel. The big tires and the traction frame cooperate, which makes the movement of the peanut thresher more convenient and saves manpower.

Advantages of our groundnut sheller

Our automatic peanut sheller machine has the advantages of a compact structure, easy operation, and stable and reliable performance. It has high peeling efficiency, low crushing rate, good sorting, and low loss rate. Our peanut sheller removing machine can peel at least 800 kilograms per hour, the peeling rate is greater than or equal to 98%, and our breakage rate does not exceed 4%.

The peanut sheller machine is driven by electricity, gasoline, and diesel, so you have many choices. To meet the needs of African customers, we have added a bracket and a traction frame under the groundnut shell removing machine. If you have this need, please contact us and we can customize it for you.

| Model | 6BHD-800B(Double drum) |

| productivity(kg/h) | ≥800–1100 |

| damage rate(%) | ≤4.0 |

| damage rate(%) | ≤3.5 |

| Stripping rate(%) | ≥98 |

| Impurity rate(%) | ≤3.0 |

| Loss rate(%) | ≤0.5 |

| Load noise dB(A) | ≤90 |

Peanut thresher Working process

The peanuts enter the front drum from the feeding hopper, and then the groundnut is peeled apart by the rotation of the suspension sleeve and the rubbing force of the concave plate to realize the separation of kernels and shells. The separated peanut kernels and shells fall through the front concave plate simultaneously and pass through the front slide plate.

In the air duct, the peanut shells are blown out of the peanut sheller removing machine by the wind to achieve wind preliminary selection; the peanut kernels and the peanuts that have not been peeled fall into the specific gravity separation sieve for selection, and the selected peanuts pass through the kernels along the sieve surface and enter the sack.

The peanuts that have not been peeled go down the sieve surface and then enter the air conveyor through the discharging trough, and the air conveyor sends them into the rear drum for secondary peeling.

Finally, the peeled kernels and shells pass through concave plate falls, and then through the preliminary wind selection, the specific gravity is separated and selected. Then all the shells can be realized.

Maintenance of peanut shelling machine

- The peanut sheller removing machine uses a triangle belt. After using the new belt for some time, it will gradually elongate and appear slack, so it is necessary to check the tension of each transmission belt regularly, whether the gap between each matching part is appropriate, and adjust it in time.

- During operation, you should always pay attention to whether the machine’s speed, sound, and temperature are normal.

- You should check the screen body’s suspension shaft and all the movable joints’ bearings in time for lack of oil and wear, and if they appear, they should be replaced in time.

- After each operation, the bottom of the sieve of the fruit rubbing machine, that is, the holes and seams of the fish scales, are regularly cleaned with a wire brush.

- After the processing season, carry out a major inspection of the peanut sheller removing machine. After the inspection, repair the damaged part to remove the dirt and residual peanuts from the machine.

- After using the peanut thresher, remove the belt and place the machine in a dry warehouse for storage. After removing the belt, hang it on an indoor wall that is not exposed to sunlight.

Something about stock and shipping

As shown in the picture below, our factory has strong strength, so we have enough stock, welcome to buy our products with confidence. The first picture is the peanut sheller removing machine without painting, and the second picture is the finished product.

Our peanut thresher looks exquisite, and you are welcome to buy it. Regarding delivery, we use wooden boxes for packaging and take adequate safety protection measures. Therefore, please do not worry about damage to the machinery during transportation.

Price of peanut thresher

Due to the different components, we cannot give you a clear price, but we hereby promise that we will give you the most considerate service and the most favorable price. You can leave your contact information and our staff will contact you within 24 hours to understand your needs, welcome to consult.

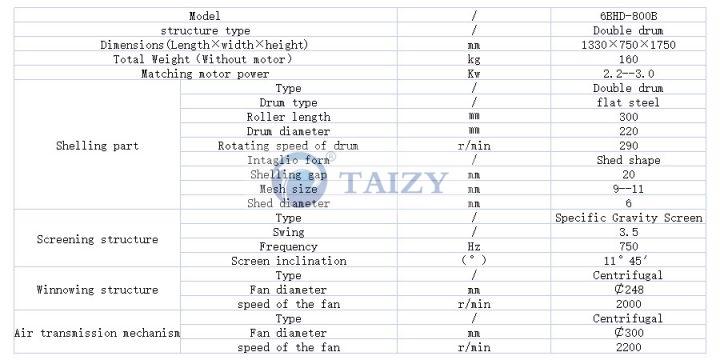

Technical parameter

Above is the detailed parameter list of this machine, this can be used for reference. If you want to know more types and details of peanut shelling machines, please feel free to contact us.