4 row peanut groundnut seed planter equipment

4 row peanut groundnut seed planter equipment

Efficient peanut sowing machine/Automated peanut seeding machine

Features at a Glance

As one of the world’s oil crops, peanuts are cultivated in large areas all over the world by using peanut seed planter equipment. Nowadays, with the development of agricultural technology, people usually use peanut seed planter equipment instead of manpower. The use of peanut seed planter machines saves a lot of manpower and improves work efficiency.

A good peanut planter’s function can improve the survival rate of peanuts and increase the yield of peanut planting. And now there are many different models and functions of groundnut seed planters on the market, which can meet people’s different needs.

Introduction of 4 row peanut seed planter

With our continuous research and development of peanut planters, we produce high-quality multi-row peanut sowing machines now. This series of peanut seed planter equipment includes 2 rows, 4 rows, 6 rows, and 8 rows.

The rest of this article mainly introduces the 2BH-4 model peanut seeding machine. This model of groundnut planter can sow four rows of peanuts. In addition to the function of sowing.

The 4-row groundnut seeder can also function as fertilization, mulching, ridge sowing, and ground sowing. So customers can choose the corresponding functions according to their own needs.

The machine needs to work with the tractor, and the connection is a three-point suspension. The machine has simple installation and convenient operation. We also have peanut pickers, peanut harvesters, and peanut shelling machine. The combination of the three machines can greatly improve production efficiency and manpower. And people can choose the different machines according to their different needs.

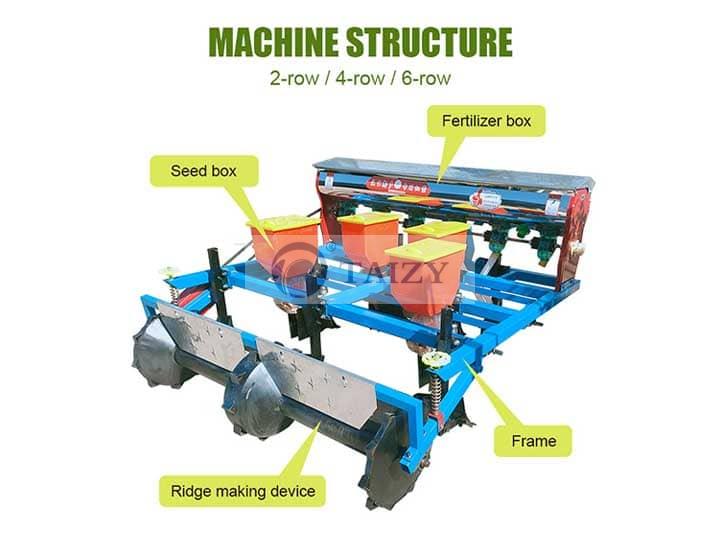

Structure of 4 row groundnut planter

The 4 row groundnut planter has the main parts of a frame, fertilizer box, seed box, seeding control system, ridge-making device(ground sowing wheel), and ditcher.

Working principle of peanut seed planter equipment

- When operating the peanut planter, the seeding quantity is precisely controlled by the seeding control system. This can ensure that the seeds can be placed regularly in the soil layer.

- The ditcher of the groundnut planter digs out the soil layer and applies fertilizer to the soil. This action will make natural seeding emergence distance. Also, this reduces the need for manual removal of the extra peanut sprouts and improves work efficiency.

- The peanut planter can complete the work of fertilization, sowing, spraying, mulching, and ridge at one time.

Working video of 4 row peanut planter

Parameter of groundnut seed planter

| Model | 2BH-4 |

| Row space | 23,48cm |

| Row | 4 row |

| Power | 22-36kw |

| Working width | 1420mm |

| Ground wheel diameter | 40cm |

Why choose our peanut seeder?

- The top screw bolts of the groundnut seeder machine are all high-strength bolts with a performance grade of 8.8.

- This peanut seeder machine series is equipped with a front ridge, first ridge, and then sowing. This ensures consistent seed depth, rapid germination, high germination rates, and higher average yields.

- The diameter of the ground wheel is increased by 480mm, so the height of the whole peanut seed planter equipment is higher 50mm than before. Compared with the traditional small ground wheel, it is not easy to be congested, and the passability is higher.

- The double-row seed metering device can effectively reduce congestion and is suitable for direct sowing after wheat harvest.

- Cooperative research and development of seed metering device that is more accurate seed metering. So, the seeds have uniform grains, fewer rotten seeds, and more secure plant spacing.

- We can adjust the width of the ridge by 60-70cm, which can be adapted to different local conditions. So, the peanut seed sowing machine has a wider application range.

If you are interested in our peanut seed planter equipment or want to get more details, please feel free to contact our sales team. We are committed to providing efficient and reliable agricultural machinery solutions to make your farming work easier and more enjoyable.