Industrial combined peanut groundnut shelling machine

Industrial combined peanut groundnut shelling machine

Combined peanut shelling machine / Groundnut cleaner and sheller

Features at a Glance

In addition to small models suitable for home use, peanut shellers also have larger models applied to factory use. Usually, the groundnut shelling machine will be used with a peanut cleaning machine. This big-sized peanut cracker unit has the characteristics of clean peeling, high work efficiency, and low impurity rate. Also, these features meet the requirements of the factory to process large quantities of peanuts every day.

Under normal circumstances, these peanuts are used to make non-staple food or to extract peanut oil. Peanut oil is an oil that people often eat in daily life. To process peanut oil, a screw oil extraction machine can be used. In addition, the screw oil press machine can also process sesame, soybean, and other materials.

Brief introduction of industrial combined peanut groundnut shelling machine

Our 6BHX series industrial combined peanut groundnut shelling machine includes 4 models. And in this passage, I will introduce the model of 6BHX-1500. This model of peanut shell remover’s capacity is 1000kg per hour. The power provider is an electric motor.

Also, this peanut shell removal machine has 2 screens, which can shell the peanut cleaner. The difference between the small-size peanut shelling and this combined groundnut shelling machine is that it works with the peanut cleaner.

The peanut cleaner can remove the clods, metal particles, peanut stems, etc. mixed in the peanuts with a fan. Then the clean peanut will be sent to the peanut shell-removing machine. Compared with other peanut dehuller machines this series machine can produce less dust. And it can help the factory process large quantities of peanuts.

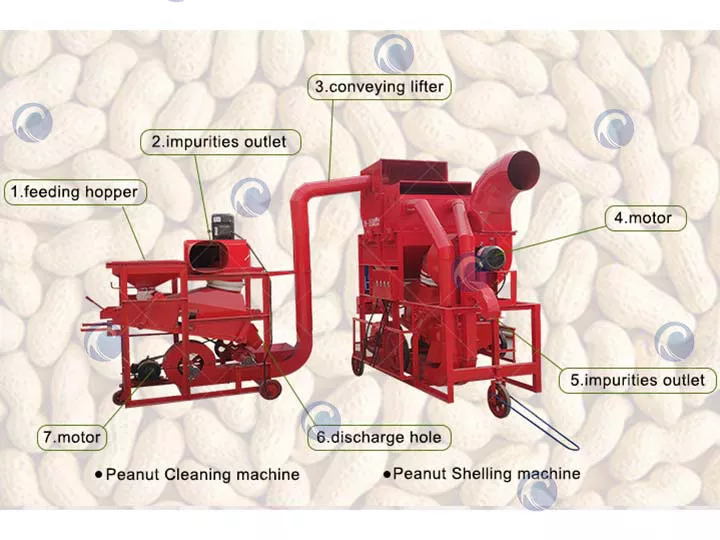

Structure of industrial combined peanut groundnut shelling machine

1. Shelling system structure

It consists of an electric motor, feeding hopper, shelling structure, grading, and sorting screen, crankshaft, suction fan, etc.

2. Peanut cleaning system structure

It includes an electric motor, feeding hopper, sorting screen, crankshaft, suction fan, and air transport device.

Working principle of industrial groundnut shelling machine

1. Peanut cleaning system

Pour the peanuts with impurities into the hopper first and flow into the sorting screen. Then the sorting screen sucks the broken leaves and floating dust out of the machine through the suction fan and the crankshaft.

Heavy sundries (soil, rocks) are sorted through the sorting screen. And then flow out of the machine from the miscellaneous discharge port. The peanuts after removing impurities descend from the sieve surface and flow into the air-conveying device. Finally, the air force transports the peanuts into the hopper of the shelling system.

2. Shelling system

The peanuts in the feeding hopper flow into the corresponding shelling drum. And the peanuts are peeled through the repeated rubbing force of the rib and the cage. When processing peanuts, all the mixed materials after shelling enter the grading and sorting sieve.

The peanut shells are discharged out of the industrial combined peanut groundnut shelling machine through the suction fan. In the grading and sorting sieve, the peanut kernels travel from the sieve surface to the outlet of the machine.

Working video of combined peanut shelling machine

Parameter of 6BHX-1500 groundnut sheller

| Model | 6BHX-1500 |

| Capacity | 1000kg/h |

| Shelling Rate (%) | ≥99 |

| Cleaning Rate (%) | ≥99 |

| Breakage Rate (%) | ≤5 |

| Loss Rate (%) | ≤0.5 |

| Humidity (%) | 10 |

| Shelling Motor | 1.5KW+3KW |

| Cleaning Motor | 2.2KW |

| Weight | 520kg |

| Size | 1500*1050*1460mm |

Advantages of industrial peanut shelling machine

1. Suspension sorting that no peanut with a shell will be missed.

2. The roller has left and right swirls and the peeling rate is higher.

3. The sealed vibrating screen box has a higher cleaning rate and prevents dust from flying.

4. The crushed peanut shells are blown out by a special fan, which can be directly used as fertilizer.

How do you choose the right industrial peanut shelling machine for your needs?

- Capacity: Determine the number of peanuts that need to be shelled per hour. This helps you to choose an industrial peanut shelling machine model that meets your needs.

- Good work performance: Pay attention to whether the final peanut kernel has a high breakage rate. Choose a groundnut shell remover with a smaller breakage rate.

- Power: Peanut shellers can be equipped with electric motors, diesel engines, etc. Choose the peanut sheller power that meets your needs.

- budget: Different models of peanut shellers have different prices, so customers can choose the right peanut shelling equipment according to their budget.

- Brand and customer feedback: Be careful to check how the customer feedback on the peanut shelling machine for the sale manufacturer.

What are the benefits of using groundnut shell remover?

- High efficiency: The groundnut shell remover has a high shelling rate and a low damage rate, allowing a large number of peanuts to be processed in a short time. This saves time and labor costs.

- Improved quality: This peanut shelling machine for sale produces clean and undamaged peanuts, thus improving the quality of shelled peanuts. This also increases their value in the marketplace.

- Versatility: The automatic peanut sheller can shell different types of peanuts, including Spanish, Virginia, and Valencia. A wider range of applications.

- Easy to operate: The industrial peanut shelling machine is easy to operate and can be learned once.

- Durable and reliable: The automatic peanut sheller is built with high-quality materials, making it more durable and reliable. It also reduces the number of repairs and the cost.

If you are interested in this industrial combined peanut groundnut shelling machine then feel free to contact us for more pictures and videos and a quote for the machine. We are looking forward to cooperating with you.