Cocoa bean peeling machine | roasted cocoa peeling machine

Cocoa bean peeling machine | roasted cocoa peeling machine

Cocoa bean shell remover/Cocoa bean hulling machine

Features at a Glance

Cocoa bean peeling machine is a machine often used for processing cocoa beans. After opening the pod, the cocoa beans need to be peeled. The best effect of peeling is to roast the cocoa beans first so that the quality of the peeled cocoa beans is high.

Working process of the cocoa bean peeling machine

When using this machine, you only need to pour cocoa beans or peanuts into the feed inlet. The machine will automatically finish peeling and screening.

How is chocolate made from cocoa beans?

Cocoa beans can make chocolate in five steps.

- Open the pod

- Fermentation

- Exposure (baking)

- Peeling

- Grinding

The pod opening of cocoa has been mentioned before, just use the cocoa pod breaker. Fermentation and exposure do not need a machine. If you are a large-scale production, you can buy a roasting machine. Today I want to share with you the peeling of cocoa beans. How to peel cocoa beans?

How to peel cocoa beans?

A cocoa bean peeling machine is a machine required for peeling cocoa. After putting roasted cocoa beans into the cocoa bean peeler machine, you can get clean cocoa beans. The peeled cocoa beans are very useful, such as making chocolate, cocoa powder, cocoa juice, and so on. Therefore, the cocoa bean peeling machine has always been our best-selling machine.

Application of roasted cocoa peeling machine

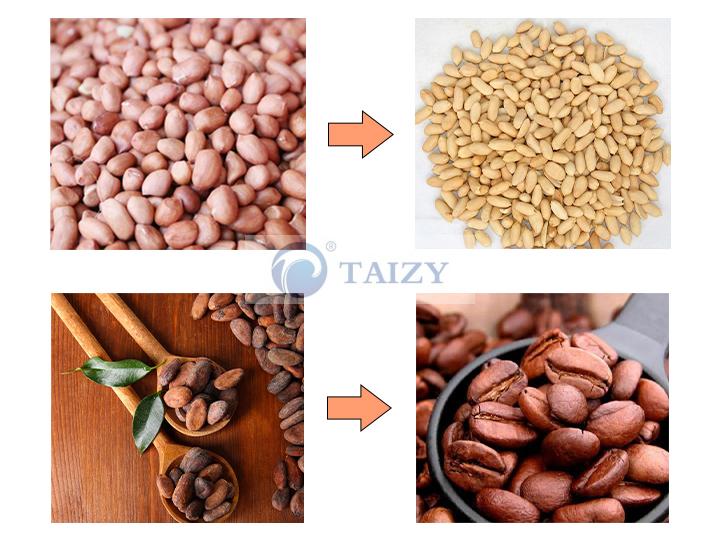

Our peeling machine can not only peel cocoa beans but also peel peanuts, that is, to remove the red skin of peanuts.

The advantages of cocoa bean peeler

- Peeling rate above 98%

- Crushing and separating cocoa hulls and bean kernels 2~3 kg per minute

- Operation is simple, almost no manual operation is required.

- The degree of automation is high, only people need to pour the materials into the machine, and the machine can automatically complete peeling, separation, and screening.

What are the requirements for cocoa beans when peeling?

- Fermentation is required so that the pulp from the cocoa beans can be separated. Do not peel the cocoa beans directly after opening the pod.

- Don’t get moldy. The way to avoid moldy is to dry and reduce the moisture from 70% to 7%.

- Cocoa bean needs to be roasted, and the husks will gradually fall off during the roasting process. This is conducive to the peeling of the cocoa beans. It is also during the roasting process that the cocoa beans absorb heat, while balancing the inherent flavor and the flavor produced during fermentation, the bitterness is also reduced and the aroma produced by roasting is absorbed.

Machine display

Technical Parameters

| Capacity | 500-700kg/h |

| Voltage | 220V/380V/50HZ |

| Power | 1.5kw*2 |

| Peeling rate | 98% |

| Size | 1900*850*1350 |

Contact us at any time

We sincerely invite all customers to actively consult and learn more about cocoa bean peeling machines. Our professional team is willing to provide you with detailed product introductions, customized solutions, and technical support to discuss how to improve your cocoa bean processing efficiency!