Great performance corn sheller丨maize threshing machine

Great performance corn sheller丨maize threshing machine

Corn thresher/Maize sheller machine

Maize sheller is a professional equipment for threshing sun-dried corn. The corn sheller has a small footprint, high work efficiency, and is easy to move. It is easy for you to move it everywhere. Therefore, this corn thresher is the first choice for household corn threshing.

As an agricultural machinery manufacturer, we are constantly upgrading the corn thresher, and the current corn thresher is the latest model. The work of corn thresher is more stable and durable.

Brief introduction of corn sheller machine

The maize sheller machine is equipped with a high capacity(3-4t/h). Owned lightweight(86kg) and 4 wheels, it is easy for farmers to move. This type of hand corn sheller has a high shelling rate and low breakage rate, which is why our customers highly praised this machine. The new design cylinder roller enables the corn not to be damaged easily.

We can equip this corn thresher with three different powers, motor, gasoline engine, and diesel engine. So it is convenient for customers to use it everywhere. We also have other thresher machines, such as multifunctional thresher machine, rice and wheat thresher, fresh corn threshing machine, etc.

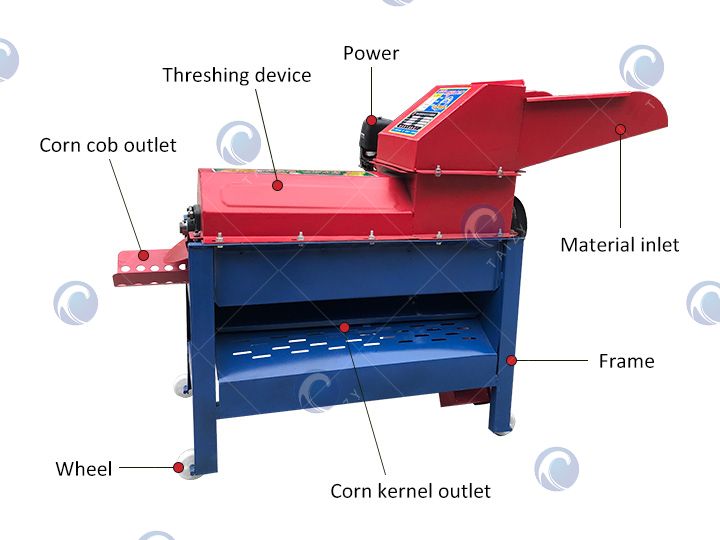

Main structure of maize threshing machine

The main structure of a maize sheller machine is mainly composed of a frame, a material inlet, a threshing device, a screen, an engine (motor, gasoline engine, or diesel engine) wheel, a corn kernel outlet, a corn cob outlet, etc. The maize threshing machine has a beautiful appearance and long service life, which is a good helper for household corn threshers.

Technical parameter of maize sheller

| Model | SL-B |

| Power | 2.2kw motor,gasoline engine and diesel engine |

| Capacity | 3-4t/h |

| Weight | 86kg |

| Size | 1080*6500*1300mm |

What advantages does the maize sheller machine have?

1. The maize sheller machine has a compact structure and high-quality steel. So people can use it for a long time.

2. High cleaning rate. Not only does the machine have a high removal rate, but the final corn kernel is also clean.

3. With special material, our new design rollers inside the machine won’t damage kernels. So, the corn kernel can be sold directly.

4. Maize sheller is easy to use and adjust, occupying small sites with high output. So it is popular in both domestic and foreign countries.

5. Its flexible structure can save labor energy and time, finishing such operations as threshing, winnowing, and screening.

Working principle of corn sheller machine

1. When the maize sheller is working, operators first put the corn into the inlet.

2. The corn enters the threshing chamber through the feeding port and then the rotor hits the corn kernels.

3. Rollers rotate under the force of the motor and thresh corn with amazing speed when corn moves into the middle of two rollers.

4. Corn cob is discharged from the tail of the maize sheller machine. The corn husks and other impurities are discharged from the draught fan that can absorb husk and some small particles to keep corn kernels clean.

5. The corn kernels fall from the sieve holes. There is a baffle in the lower part of the inlet to prevent the falling corn kernels from injuring people.

Note: The threshing efficiency of the corn thresher is determined by the length and diameter of the drum. The spike on the rotor is vulnerable. And we should check it frequently. When it wears a quarter of the teeth, we can correct or replace it with electric welding to ensure the balance of the rotor. The screen is a consumable part as well. So, we should replace, it when it is broken.

Application of corn sheller machine

Maize sheller separates the corn kernels from the cobs at an amazing speed and the kernels can remain intact, which is widely used for livestock breeding, farms as well as daily use by people.

The successful case of corn sheller machine

Our customers are very satisfied with the maize thresher machine very much due to its low crushing rate, excellent ability towards cleanness, and high efficiency. Until now, we have exported many corn threshing machines all over the world.

And received good feedback from them. With perfect after-sale service and a sincere attitude, we have gained the trust of customers. We always put our feet into the customer’s shoes and treat their benefit as a priority.

FAQ

Does this machine only thresh corn?

Yes, it is the machine only for corn.

What is the vulnerable part of this machine?

The roller and screen are vulnerable. And we should replace them frequently.

How many types of corn sheller machines do you have?

Corn sheller machine is our hot sale product. We have different capacities such as 1t/h, 3 -4t/h,4t/h,5t/h,6t/h. Welcome to contact us to know more.

How to change the screen?

The screen is easy to change. We will provide you detailed video of changing the screen.