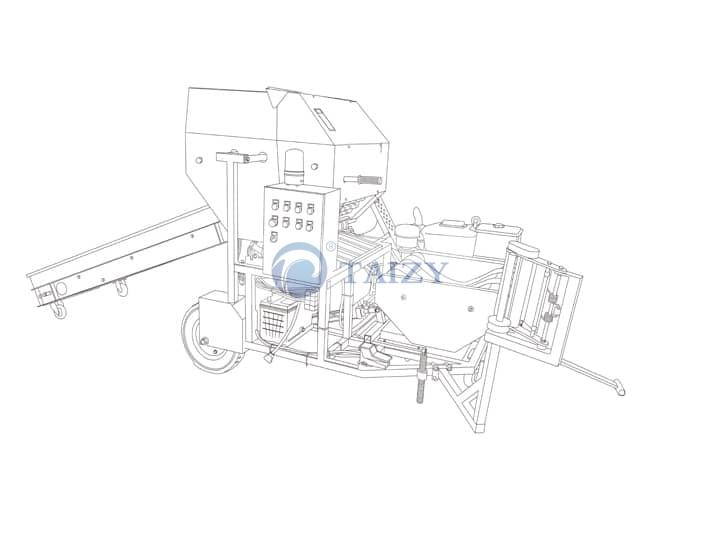

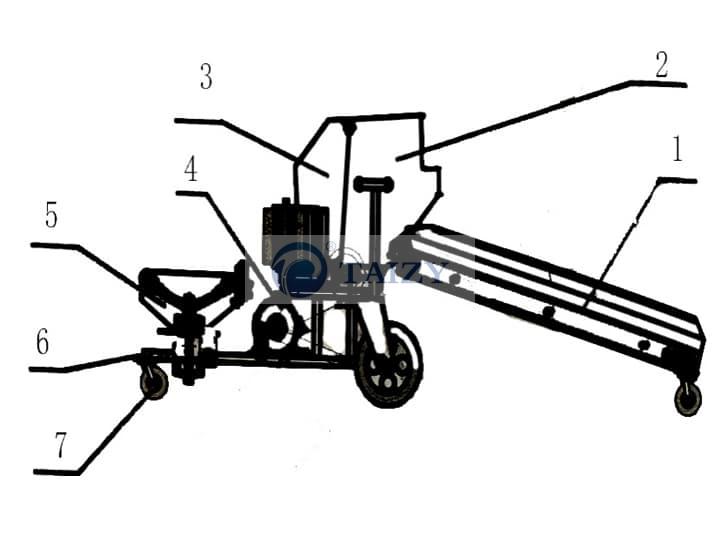

Overview of Silage Baler and Wrapping Machine

silage baler and wrapping machine is a fixed bundling machine. It is the only equipment in China that can reliably feed, bundle, and wrap the rubbed corn stalks. The bundled corn stalks have a high density, which is convenient for storage. This silage bundling machine can also bundle other dry and fresh grasses. It is one of the necessary equipment for animal husbandry.

The silage must have a certain humidity, which is an important condition to promote the fermentation of lactic acid bacteria. Generally, the moisture content of silage is 65%~75%, and for legumes, 60%~70% is the most suitable.

The forage bales that are bundled and wrapped by the machine can keep fresh, maintain and promote fermentation of the forages. It is good silage and is easy to transport.

Working Principle of the Silage Strapping Machine

Sequences of the feeding part

The motor power drives the air compressor to run. The compressed air generated by the air pump is delivered to the air storage cylinder to the air pressure of the air storage cylinder. When the working pressure (0.6~0.8Mpa) is reached, turn on the switch of the air storage cylinder to supply air to the solenoid valve of the silage strapping machine.

Turn on the green start button of the distribution box. After the standby machine runs normally for 3 to 5 minutes, an operator will evenly spread the straw on the conveyor belt. The conveyor belt will gradually transport the straw to the silo of the baler. The rotating rolling roller drives the straws to rotate together, and as the straws are fed in, the bales gradually increase.

After the straw in standby, the warehouse is full and reaches the set density. The inert roller rotates to drive the signal wheel to rotate, and the sensor transmits the signal to the alarm light. The alarm light buzzes, and the conveyor belt stops. At this time, the operator should stop placing the straw, the control system issues an instruction for the first time. The winding mechanism rotates, and the winding starts.

Process of the bundled film part

After the hemp rope starts to wrap around one circle from the left end, it returns to the cutter position, the blade cuts the hemp rope, and the winding ends.

The control system issues a command for the second time. The opening cylinder moves, the cylinder rod extends, the movable door opens. The bale automatically rolls down to the rotating frame of the silage baler and wrapping machine under inertia. The cylinder rod contracts, the movable door closes, and the conveyor belt turn, the baling will automatically enter the next working cycle.

The control system issues an instruction for the third time. the film motor rotates, the film holder clamps one end of the film, and the film starts. After two turns, the film holder loosens. when the film is wound to a predetermined number of layers, the film stop, the rotating frame returns to the starting position.

The control system issues a command for the fourth time, the cylinder rod of the package turning cylinder moves out, and the packaging machine turns over.

In the process of turning, the blade cuts off the film, while the film holder clamps the film. The bale falls on the transport trolley, the cylinder rod shrinks, and the silage bundling machine falls to the working position. The wrapping machine automatically enters the next job cycle. Another operator transports the bale to the storage location.

Working Video of Silage Bundling Machine

This video showed us the whole baling process of the silage bundling machine, and the same is true for silage making.

If you want to make silage, you can contact us directly.