Combined rice mill | Rice milling and crushing machine

Combined rice mill | Rice milling and crushing machine

Combined rice miller/Paddy rice processing machine

Features at a Glance

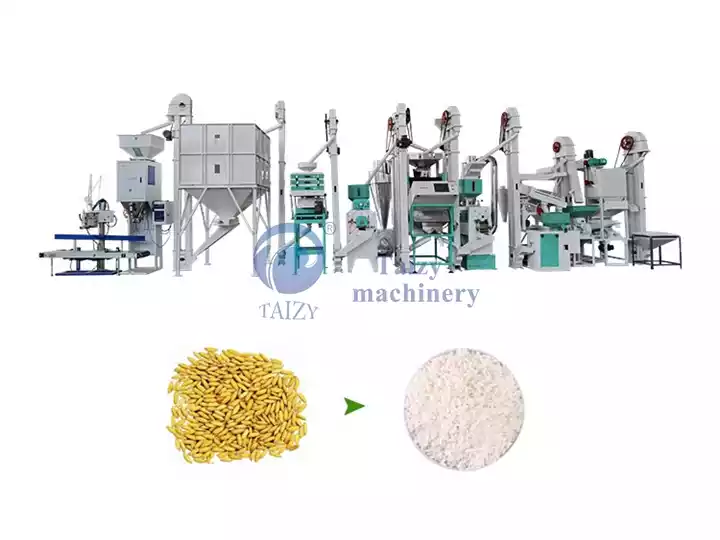

Introduction of rice milling and crushing combined machine

The combined rice mill adds a crusher to the rice milling machine so that one machine has two different functions. In this way, not only can one machine be used for multiple purposes, but also the production cost of customers can be reduced.

At the same time, two machines use one motor, which is more efficient. It is suitable for crushing corn, soybeans, pepper, medicinal materials, spices, etc. So it is widely used in factories, rural households, feed processing plants small businesses, and other places. In addition, customers can choose different models and different outputs according to their own needs.

Structure of rice milling and crushing combined machine

The machine is mainly composed of four parts: rice machine, grinder, motor, and frame. The combined rice mill is composed of a machine cover, a rice roller, a rice sieve, a blade, a feeder, a separator, a pulley, and an adjustment device. The crusher is composed of a feed hopper, a crushing chamber, a discharge port, a frame, and other parts.

Advantages of combined rice mill

- The rice milling part of this machine can process rice into rice at one time, and complete the separation of rice, bran, and broken rice at the same time. The crushed part can be used to crush rice, corn, sorghum, beans, potatoes, and stems.

- The fuselage is made of high-quality materials, thickened steel plate, sturdy and durable, beautiful and generous.

- Excellent engine, with strong and stable power.

- This combined rice mill has the advantages of a reasonable structure, compact model, simple operation, convenient maintenance, fast rice milling speed, low power consumption, safety, and reliability.

- The rice milling chamber adopts one-piece casting and the design of support at both ends makes the rice roll more stable, effectively reduces the rate of broken rice, and prolongs the service life of the rice roll.

- The rice milling design of the rice roller supported at both ends makes the rice roller more stable during operation, effectively reduces the rate of broken rice, and prolongs the service life of the rice roller.

- The traditional rice knives are replaced by rice rolls, made of stainless steel, and the performance is superior. The steel fan tube is more durable, not easy to break, and has a long service life.

- You can choose the gap size of the rice sieve for installation.

Working principle of rice milling and crushing machine

Rice milling part:

The rice enters the rice milling chamber through the feeder, and then the rice is squeezed by bearings and rice blades. In this step, the rice will be hulled and discharged to the discharge port.

The unique discharge port design separates the whole rice from the broken rice. At the same time, the broken rice bran will enter the bran bag through the screen, and the user can use the bran powder as feed.

Crush part:

The raw material is constantly hit in the high-speed rotating gear disk and then becomes powdery. And use screens of different sizes to control the particle size of the powder.

Work video of rice miller

Combined rice mill parameter

| Model | 6N80-9FZ23 combined rice mill |

| Rated motor speed | 1600r/min |

| Meter roll diameter | 80mm |

| Rice machine productivity | ≥150kg/h |

| Rice output rate | ≥65% |

| Broken rice rate | ≤30% |

| Diameter of the sieve ring | ≥150kg/h |

| Rotor diameter | 230mm |

| Diameter of sieve ring | 280mm |

| Screen size (mm) | 840×100 |

| Accessories | In and out of the hopper, 2 sets of screens, protective cover, motor wheel, V-belt |

Model and configuration

Among the existing basic models, you can choose single-bucket or double-bucket rice milling and crushing combined machines, combined machines, and cabinet-type rice milling and crushing integrated machines. In addition, in the upgraded model, you can choose the one with the claw grinder, or you can choose the one with the grinding and refining function. At the same time, the power choice of our combined rice mill is a high-quality motor, which can extend the service life of your machine.

Contact us at any time

If you are interested in our advanced combined rice mill machine, please feel free to contact our professional team for more details. We are happy to provide you with customized solutions to meet your rice processing needs.