Electric Grass Mixer Silage Spreader Animal Husbandry Feeding Car

Electric Grass Mixer Silage Spreader Animal Husbandry Feeding Car

Grass Mixer Silage Feeding Car | Cow Cattle Feed Spreader

Features at a Glance

The silage spreader is primarily used to mix silage feed or other feed evenly and then quickly and uniformly spread it into the feeding areas for cattle and sheep. Using this equipment can increase feed utilization by 15%-20%, significantly reducing waste.

This machine integrates mixing, transportation, and spreading functions, offering convenient operation and high efficiency, enabling scientific and large-scale feed distribution.

It not only effectively improves feeding efficiency and farm management standards but also ensures that cattle and sheep receive balanced nutrition, thereby promoting healthy growth and reducing feeding costs.

Silage spreading machine applications

- Livestock feeding for farms: suitable for large-scale farms and family-run livestock operations, this system is designed for feeding ruminant animals such as cattle and sheep with silage, straw, forage, and pellet feed.

- Compatible with multiple feed types: capable of processing various feed materials including corn silage, straw meal, hay, and compound feed.

- Multi-environment application: whether in open pastures, barns, or semi-enclosed farming environments, it can operate flexibly to ensure even feed distribution.

- Suitable for different farming scales: suitable for both small family farms and large livestock companies, with options for different capacities and models based on needs.

Animal husbandry feeding car benefits

- Highly efficient and energy-saving: several times more efficient than manual feeding, with a single machine capable of feeding hundreds of cattle and sheep per hour.

- High feed utilization: even distribution of feed prevents selective eating and waste, improving feed utilization by 15%-20%.

- Reduced labor costs: automated operation significantly reduces labor input and lowers labor costs.

- Flexible and maneuverable: compact design and flexible operation allow free movement and operation across various terrains and farming environments.

- Safe and reliable: constructed with wear-resistant steel and a high-performance transmission system, the machine features a robust structure, long service life, and simple maintenance.

- Promotes livestock health: ensures livestock receive balanced nutrition, promotes healthy growth, and improves marketability and milk production rates.

Types of silage spreader

According to your needs, we provide different types of silage spreader trucks, you can choose according to the actual situation.

Vertical and horizontal silage spreader

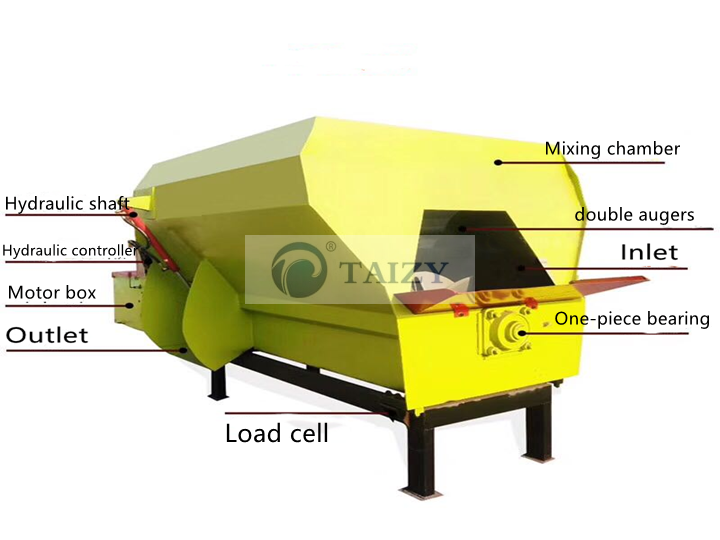

The only difference between these two types is that the vertical is cylindrical and the horizontal is cubic. Volumes are available in 3 and 5 cubic meters. The two pictures below demonstrate their differences.

Electric vehicle-driven spreader

This type of silage spreader uses an electric vehicle as its power source and is usually equipped with a powerful electric engine.

The advantages of electric drive are environmental friendliness, low noise, and low energy consumption, making it suitable for applications that require working in a relatively quiet and clean environment. At the same time, electric models offer excellent flexibility and controllability, making them easier to operate in limited spaces such as pastures and farms.

This machine needs to be fitted with a separate mixer to spread the silage bales (usually handled with a bale wrapper, which has the effect of preserving the fermentation. Related article: Silage Baler Machine | Full-Automatic Silage Baling Machine) This is then given to the silage spreader via a conveyor belt.

Diesel model cattle feed spreader

This machine is also driven by an electric vehicle, but the machine is equipped with a diesel engine, so that the self-contained mixing function, directly after mixing and feeding, there is no need for a separate mixer.

The advantage of the diesel engine is the high energy density of the fuel, so that it can provide a sustained and strong power output over a long period, suitable for a long time, high-intensity use.

How the cow cattle feed spreader works?

The working principle of silage cattle and sheep feed spreader is divided into two main steps:

Feed loading

First, the operator loads the silage (usually chopped forage or plants) into the container of the spreader. This may be done by a mechanical loading system or other loading equipment.

Some spreading wagons may also have a mixed loading feature that allows different types of forage to be mixed to ensure livestock receive balanced nutrition.

Spreading process

Once the feed has been loaded, the silage spreader truck spreads the feed evenly over the feed area through a mechanical system.

This is usually accomplished by rotating a fan or circular spreader. The spreader adjusts the extent and density of the spread to ensure that the feed is evenly distributed throughout the livestock feeding area.

The speed at which the vehicle travels and the speed at which the spreader rotates can often be adjusted to meet the needs of different feeding sites.

Parameters of silage mixer spreader

| Model | SL-3 |

| Overall size | 3.6*1.5*2.0m |

| Bin size | 2.0*1.2*1.4m |

| Belt width | 400mm |

| Number of batteries | 6 |

| Input voltage | 72V |

| Battery specification | dry battery Chaowei or Camel brand |

| Tire model | Rear wheels 3.50*12(2) + 5.00*12(1) |

| Bin size | 3m³ |

| Bearing | F206(4) |

| Conveying method | apron |

| Spreading method | bi-directionality |

| Brake | oil brake |

| Spreading height | 60cm |

| Transmission | chains |

| Steering wheel | knobbed |

| Electric motor | 1.5/1.5/2.2 |

| Battery capacity | 70A |

Contact us at any time

If you are interested in our silage spreader, please feel free to contact us for more detailed information about the machine. We will be happy to provide you with detailed product descriptions and customization suggestions to meet your specific needs. In addition, we also welcome you to visit our factory, and we look forward to working with you to create more efficient and intelligent feeding solutions.